Contents of this page:

- Colour Print

- Control Panels.

- Security

- Duty Cycle

- Print Speed

- Multifunction & Scanner

- Copy Abilities:

- Fax Abilities

- Print Resolution

- Paper Handling

- Paper Trays

- Duplex

- Optional Paper Handling

- Maximum Capacity

- Processor

- Memory

- Interface

- Network

- Network Protocols

- Print Languages

- System Compatibility

- Power

- Power Consumption

- Environment

- Dimensions

- Weight

- Acoustic Noise

- Consumables

- Maintenance Kit

- Spares

- Fault Finding

- Service

- Options

Systematic Information:

There are more than 60 printer manufacturers![]() and many thousands of printer designs. To have information readily to hand and make comparisons between products information needs to be collected systematically.

and many thousands of printer designs. To have information readily to hand and make comparisons between products information needs to be collected systematically.

A framework for systematic collection of information follows. Each of the items we research gets a brief comment. The lists of printers and spares are here![]() .

.

The question today is not whether you want colour print, so much as whether you very deliberately choose black and white. Colour is there on the cheapest printers in the supermarket. You have to deliberately buy a mono laser-printer to lose the colour and cut printing costs.

Colour print has a high social value because it was once difficult to achieve. Printing processes put one colour of ink on the page, usually black because that gives the greatest contrast. The four-colour-process to print colour illustrations in books was developed in the late 19th century and uses three coloured inks, Cyan, Magenta and Yellow plus Black. Each colour subtracts its complement from the light reflected from the page, so yellow subtracts all the blue light but leaves the red and green. There is more explanation here ![]() .

.

Running a succession of colour presses to achieve colour print is obviously more complicated than having just one, but by the 1970s computer control of printing presses and low cost printing inks lowered costs so that previously staid journals like the Economist

and New Scientist

switched to colour. By the mid 1980s even the FT

had coloured pictures - a bit of an effort because it doesn't work naturally with their traditional pink paper.

Computer colour print was once done with £2,000 pen-plotters or £20,000 colour copiers. Neither was commonplace.

Colour Inkjets

Low cost colour inkjet printers were quite an innovation when they first appeared in the early 1990s. Printing photos from a digital camera on the desktop was an exciting new possibility. For instance the highways department of a council got one of the first Kodak digital cameras and a Canon BJC-600 inkjet; they were able to cut the response times for changing road layouts in response to an accident from months to days because they could communicate the problem straight away.

Some jobs just demand colour. It is possible to distinguish the segments of a pie chart or the strata of geological traverse using various kinds of shading but colour gives a dramatic rise in comprehension.

Adding the colour mechanism to an inkjet printer doesn't cost printer manufacturers all that much. The change in the printer is a few extra drive circuits and connectors for the cartridges. Inkjets are quite slow, so a nearby computer does page formatting as a background task. The complicated works are in the printhead but they are mass-produced by techniques similar to chip-making. The user pays to buy a succession of cartridges and printheads, so meeting this after-market is profitable business for printer makers.

Colour Laser Printers

Making a colour laser printer is significantly more complicated than an inkjet. However it didn't take laser printer designers long to catch on that people wanted colour, and that people with colour printers use more cartridges, so it was a very profitable idea.![]() .

.

Most colour laser printers use four inline toner-developer-drum sets (all three parts are often in one cartridge) and a transfer belt. The mechanism can be packed quite neatly, although the machines are often heavy and full of precision parts. Minolta were the first to get a colour laser printer to market for under £1,000 in 1999. Now it is possible to buy a colour printer for £150, although beware of the ownership costs as the cartridges are used up. A machine for everyday use with a set of full-life consumables is still likely to cost £1,000.

Printer manufacturers are naturally very keen that users should have colour. They suggest ideas like - colour print for the cost of black and white

. Could these promises hold true?

Colour laser printers are quite complicated. It is possible to almost entirely disengage the colour mechanisms so that only one toner, developer and drum are in use but that isn't how most colour printers work ![]() .

.

Colour Cost

Ink on paper costs money; use more ink and it costs more money. Page-cover almost inevitably goes up with colour; photos and pie charts can use a lot of ink. Given the extra complexity of a colour printer it is unlikely that running costs will be lower than for a mono printer.

Printer makers basically want to sell colour because users will be much more inclined to print big, bold, full-colour pictures using their proprietary toners and inks.

Of course it is possible to have lower cost colour print - all the manufacturers have to do is cut the cost of their cartridges. Both Kodak and Kyocera have promised much better economies. So far the main way people cut costs is to use refurbished or compatible cartridges.

If you run an office and print business forms, with just the odd need for a colour report or photo, then it's probably sensible to use a mono laser printer for the main task. Get an office-quality inkjet to handle those odd colour tasks. It's usually a good idea to have more than one printer anyway. (To the best of our knowledge there are NO mono inkjet printers - colour is compulsory on inkjet printers)

If printer running costs really are a huge concern then consider dot matrix printing![]() .

.

If producing brochures and marketing material is a significant part of the job then although a colour laser printer will cost a bit more to run it is the right tool for the job. There is a choice between the colour laser printer or professional printing. Professional printing is usually cheaper where the print run is greater than a few thousand sheets and there is the convenience that you just order the job and collect the box of print. Short runs of a few hundred are normally done with a laser printer. If there is a lot of short-run work consider a laser printer with big 2-piece cartridges and document finishing machinery. Some printer manufacturers now claim their inkjets can run for less than the cost of a laser printer. Establishing that will take a while![]() .

.

Controls & Features: | |

Control panels are not very important to the actual working of a printer but make a difference to the user experience. A shared printer really needs a control panel. So does a multifunction printer intended to work as a fax or photo printer without a computer.

No Control Panel

A printer can have no control panel at all, relying entirely on a nearby PC and printer driver to provide all the user interaction.

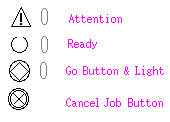

In practice even the lowest cost printers usually do have a couple of lights and buttons. Even with lights one of the common reasons for "my printer doesn't work" help calls is that it isn't turned on. Designers could make the lights brighter.

Printers with just a few lights often flash them in clever

ways to signal errors like low toner or defective fuser. The problem with this is that the user is expected to look up the pattern in the user manual and they have probably lost it.

Handy hint: type the name of your printer in quotes and filetype:pdf into a search engine for instance:<<"laserjet 1018" "user guide" filetype:pdf>>

One or two manufacturers seem to have some odd objection to the user manuals being available online.

Control Panel

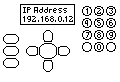

Business printers usually have a control panel to tell users their status and allow the set-up to be changed. This is particularly useful on network printers, where the printer needs to be given a fixed IP address![]() .

.

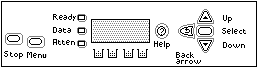

Recent printers sometimes have sophisticated control panels; this allows them to work as multifunction copiers and picture printers independently of a computer.

Printers often have a great many control panel options and may be able to print out a chart of them to help. However in most cases the computers override the printer settings. So if the printer asks for letter-sized paper every time you print it is likely to be the default US

settings in the PC (or another on the network) doing it - not the printer.

Most of the options in the printer itself are defaults

for print jobs that don't specify something else. For instance the printer might default to print courier on letter-sized paper but the computer will override that using PJL / PCL (or whatever control language) and specify arial on A4. Default settings are only likely to be used when printing from a command prompt or using the Unix lp

command; if the printer were set for US paper but loaded with A4 it would then give the PC-LOAD-LETTER

error message.

Ease of use is important, particularly in a business where several people share a printer and some of them will know very little about it. A big display with lots of help messages is useful.

Printers with keypads and bigger, better LCD screens make several things practical. Setting up defaults such as printing 2 pages per side and duplex (although again, look at the PC settings first). Document storage in the system until the printer gets a PIN releasing the print to the user. One use for the good LCD displays comming into fashion is to give a preview of the page just before it prints giving the user the chance to abort the page or the whole job if they don't look right.

Security: |

In an organisation some of the things printed are not meant to be seen by everyone. Medical and legal practices are an obvious example where people might expect documents to be restricted to a need to know basis. Accountants, personnel and design offices also handle confidential information.

Some printers offer security features, like the ability to hold onto prints until the control panel gets a PIN showing the right person is present.

Logfiles and PINs can also be used to identify who is printing what. Some offices find that the ability to print holiday snaps gets out of hand. Users can be assigned privileges

like colour print, or print quotas.

Duty Cycle: | |

Duty Cycle is a gauge of how much work the printer can reasonably asked to do. A small, lightly built printer made largely of plastic with a small cartridge probably won't last as long under heavy use as bigger machine with a metal chassis and a big cartridge. Some way to state the expected use of the printer is needed.

Manufacturers often suggest their expectations as a duty cycle

, saying how many pages per month can be expected. It is commonly implied that this is some sort of measure of how many pages a printer can print without wearing out it's components. This idea may have some merit, for instance, many of the cogs are "lubricated for life" so if the cogs run non stop the lubricant will be exhausted too quickly.

There is often a recommended use

level given as well, particularly for recent printers. The maximum duty cycle is often much higher than recommended monthly usage. Recommended use and duty cycle are related to the size of consumables. Bigger and more expensive printers have bigger drums and toner hoppers that handle more printing.

The real use of a duty cycle is probably to limit warranty claims. If a printer is rated for 5,000 pages per month and a warranty call comes in after 6 months and it turns out it has printed 50,000 pages the service engineer (and the manufacturers legal team) are likely to say it's outside our warranty terms

. Customers who have (ab)used a small printer in this way might expect them to be grateful - using all those cartridges must have helped their budget! But no; you'll be asked to pay for repair.

Print Speed: |

Print speed is one of the key characteristics of a printer, particularly in business use. If a printer will be used very frequently then doubling it's speed will cut down the queue of users. Some jobs may be impossible with a slow printer. For instance if there will be ten people in an 8am meeting and they each need a 6 page copy of the minutes a 60 page per minute printer will do that with almost no interruption - but a 6 page per minute printer is going to need 10 minutes to do the job. Similar considerations apply in offices and shops where people might wait for the print-out

Fast printers characteristically have bigger motors, which implies bigger driver chips and a more substantial power supply. There isn't a complete deterministic relationship, a small printer might be fast if it has an exceptionally small cartridge. Some sort of proportionality between the printer size, expected duty cycle and cartridge size is normal.

Speed is often counter-posed to resolution: some printers slow down when asked to print a high quality image.

Inkjet Speeds

Inkjet printers are notable for slowing down to give higher quality images. The printhead only has so many nozzles which can fire at some given frequency. Asked to print at high speed the motors run fast but the ink doesn't have much density on the page and accurate positioning of dots might suffer as well. Asked to print at high quality the machine slows right down, increasing the dot density (and the accuracy). Many inkjet models can achieve high speed but only at the cost of giving low resolution. The headline speeds given for inkjet printers are often for draft quality

and are hopelessly optimistic for ordinary use.

A new breed of pagewidth inkjet printers claim print speeds of 60 pages per minute and may be able to sustain that. They aren't cheap, partly because they have built-in processor and memory like those of a laser printer. However they are an interesting development.

Laser Printer Speeds

Laser printer speeds are usually more realistic than those given for inkjets. If a laser printer is rated for 30 pages per minute it is surprising and worth investigating if it is very much slower. The problem is usually memory - laser printers can need a large amount of memory to "rasterise" the page - turn the print language into the page image in the formatter

.

Laser printers can't actually print slowly; they print at the rated engine speed. There may be two engine speeds, many older printers ran at half speed to achieve 1200 dpi for instance.

Laser printers do respond slowly (and sometimes not at all) when they run short of memory for the page image. Reports of a laser printer being "slow" usually mean it waits between pages. Typically, the printer is attempting to format a complicated page, a photograph, map or pdf. Some web pages (like Google maps) and PDFs that have been scanned in can be more complicated to print than they may seem ![]() . Many printers have slots for expansion memory. Alternatives are to change the print language, using PCL rather than PostScript may halve the memory footprint. Using 300dpi rather than 1200dpi cuts the size of an A4 bitmap from 16 megabytes to 1 megabyte.

. Many printers have slots for expansion memory. Alternatives are to change the print language, using PCL rather than PostScript may halve the memory footprint. Using 300dpi rather than 1200dpi cuts the size of an A4 bitmap from 16 megabytes to 1 megabyte. ![]() The relevant settings for page resolution and print language are in the computer's print control panel (the computer settings will usually override those in the printer)

The relevant settings for page resolution and print language are in the computer's print control panel (the computer settings will usually override those in the printer) ![]() .

.

Older laser printers often have a speed / quality tradeoff as well, asked to print photographs at 1200 dpi the printer may slow down to half speed. The laser in the scanner doesn't have the speed to generate an accurate image at full speed. The formatter may need extra time as well. With recent laser printers there doesn't usually seem to be any down-rating of speed caused by higher resolutions.

Computer Power

Print speeds naturally cannot be higher than the computer or network feeding them. Computers can to be too slow, classic signs are an unresponsive mouse and the hard disk light constantly on as the machine makes excessive use of swap memory.

Printers can slow a computer down. The classic problem is that low cost printers rely on the computer to do the page formatting and that can consume quite a lot of memory, pushing the computer into that problem with swap memory.

One reason to use a network-attached printer or a print-server rather than use Windows printer sharing is that the latter tends to slow the computer down. This can be particularly noticeable with dot matrix printers. When a print-job is sent the computer is bogged down servicing frequent printer interrupts for more data.

Multifunction & Scanner Abilities: | |

Having a printer that can double as a copier is very useful, particularly in a small office ![]() . Scanners are common on modern printers which double as copiers, fax machines and as the front end for document management systems. Single sheet copying of pages that are guaranteed flat just needs a simple flatbed scanner. Pages from books may need a more complicated CCD camera based scanner. Multi-page documents benefit from a scanner with an Automatic Document Feeder. A duplex printer might have a duplexing ADF - one that can turn the document over and scan the other side.

. Scanners are common on modern printers which double as copiers, fax machines and as the front end for document management systems. Single sheet copying of pages that are guaranteed flat just needs a simple flatbed scanner. Pages from books may need a more complicated CCD camera based scanner. Multi-page documents benefit from a scanner with an Automatic Document Feeder. A duplex printer might have a duplexing ADF - one that can turn the document over and scan the other side.

There is sometimes a distinction between AIO

All-In-One

printers which are usually inkjet based printers and Multifunction

devices which tend to be more office oriented. An AIO is likely to have good features for photographic work; SD slot, PictBridge and DVD burner software. A Multifunction printer might lack those features but have an ADF, document finishing options and automatic FTP upload.

Copy Abilities:

Copy abilities vary. Multifunction printers can scale what they copy over the range 25% reduction to 400% zoom. Some multifunction printers have higher resolution scanners with better colour range suited to photography. And some scanners have CCD cameras which give a good depth of field to cope with the book bindings.

Fax Abilities: |

Faxing is a relatively simple addition for a multifunction printer - all that is needed is some extra software to control the fax dialogue and a modem to interface with the phone line. Faxing is a curiously popular method of communicating given that it tends to need the expense of an extra phone line and that scan to email would usually do much the same job. One explanation is that a signed fax has legal status in some countries whilst and email does not.

Print Resolution: |

People naturally want to know how a printed page will look. Page appearance isn't something that can easily be summed up on a specification sheet, but print resolution is a factor.

Print appearance has been largely a matter of the maximum resolution the printer could give until quite recently. This in turn is partly a matter of the technology used, with dot-matrix and thermal printers giving low resolution of around 200 dots per inch, laser-printers mid levels around 1200 dpi and inkjets designed for photography boasting 4800 dpi or more.

Giving a figure for print resolution is used as a way to summarise print quality. There are actually several issues submerged in the figure:

- Resolution is really a matter of the finest mark a printer can make. At 1200 dpi that mark is just over 20 microns across, so its microscopic (0.02mm) . Some plotters - wide-bodied printers intended for diagrams - do have a minimum line size on their specification sheet.

- Resolution is often used to suggest how good the printer will be at producing photographs, where higher figures mean more complicated dither patterns and better looking photos. However there are other things that contribute to how good photographs look: number of ink colours, overprinting and colour mixing, dot-gain, dot contrast, colour purity and dot modulation or greyscale.

- Pictures won't look good at very low resolutions but beyond a certain point (probably 1200dpi)the software interpreting the picture on its way from camera to paper will be at least as important as the physical dot size. The computers printer-driver and the raster-image processing software in the printer formatter are important. Resolution doesn't always tell the whole story.

Human visual acuity is around one minute or arc. Very approximately this might be something like 6000 lines vertically and horizontally for one eye (it could be less, but eyes continually saccade). Computer screens with 1280x1024 SXGA resolution usually fill a part of the visual field, an HDTV 1920x1080 screen might fill a bit more. The current generation of screens don't entirely satisfy what our eyes could do. Paper documents are more tried and tested.

A typical A4 / US-letter document tends to occupy about half its readers visual field horizontally, a bit more vertically. Paper tends to be used in portrait

orientation; this seems to be chosen because there is a limit to how far we can saccade the eyes and accurately position to the next line which makes very wide columns of text uncomfortable.

Conventional printing presses such as offset litho compose pages using a dot-pitch of 300 dots per inch or 12 dots per millimeter. There are various reasons to think that this is adequate for text. For instance Latin text needs to be 9 pixels high to resolve the letter forms clearly so it would allow text 0.7mm high- about 2 point - which is smaller than anything normally used. Ordinary text is about 2.5 mm high and 300 dpi gives 30 pixels height, sufficient space for the letter forms to be very clear and to add artistic flourishes like serifs.

There are a few possible uses for graphics at 600 or 1200 dpi, it is possible to see hair thin lines although it isn't easy to discern dots without a microscope.

The main purpose of higher resolution in print is usually to improve the handling of continuous tones or greyscales

in photographs. Chemical photography is unusual amongst mechanical print processes in producing black, white and every level of grey. Colour photographs expose three layers with colour filters so they are still effectively greyscales. Digital cameras typically take pictures with 8 bits (256 levels) per colour channel.

The most cost-effective print mechanisms can only manage bi-level or binary

print, at any one point the paper is either coloured or it is not, a black mark mark can't be made into a grey mark.

Printing presses use a method called halftoning to give an appearance of grey. The image is turned into dots at a pitch somewhere from 65 lines per inch to 300 lines per inch. From the 1880s through to the 1980s this was done using optical techniques, the result being dots of ink of varying sizes. In the 1990s digital typesetting machines took over the job, these worked internally at 2400 dots per inch to produce plates at 300dpi. To make the greys of a black and white photo print presses print larger and smaller black dots. For various reasons to do with speed, economy and the absorbency of cheap paper the dots on newsprint are at 65dpi, large enough to be visible. Desktop computer screens are usually at about 85 dpi and at normal viewing distance dots are scarcely visible. Normal books use 300 dpi and dots are not normally visible. Artistic material might be at 600dpi.

There are a whole range of possible digital print technologies: photo-printing, dot-matrix, laser-print, piezoelectric inkjet, thermal inkjet, thermal direct print, thermal transfer and dye sublimation.

Photo-printers, dye-sub and piezoelectric inkjet can all manage some measure of dot modulation, they can vary the size or intensity of a printed dot. Photo printers have never been common although there were a few polaroid based devices. Typesetters were often based on photographic film. Dye sub tends to be expensive to operate and is mainly used to do things like decorate short-run and personalised ceramics. Dye sublimation printers can produce very good looking photos at 300 dpi because they have a greyscale ability.

Piezoelectric inkjets use the way some crystals flex when an electric field is placed across them to eject ink from a nozzle. A very similar mechanism is used in quartz watches, but inkjets tend to use a ceramic material called lead zirconate titanate. Almost all big commercial inkjets use this technology. Epson developed Micro-Piezo heads in 1994 and got an early lead in photo printing using small printers.

Thermal inkjets originated as a way to produce lightweight printers with disposable printheads. However, the printhead manufacturing process began to share technology with chipmaking, including it's ability to double the number of nozzles every couple of years. The HP DeskJet introduced in 1988 had 50 nozzles, a resolution of 300 dots per inch and a price of $995 but the speed was rather low. By 2008 machines like HP's Officejet Pro K8600 had 1056 nozzles per printhead. Inkjet specifications once commonly gave the number of nozzles but it seems to have become a non-issue. One exception is where the printer has a pagewidth head.

Dot matrix printer designers did try to shrink the print pins and increase their number. When pin size fell below 0.2mm and numbers grew beyond 24 pins got bent too easily. Dot matrix printers tend to deliver less than 300dpi, or they are slow producing pictures. As a result they now tend to be confined top work where pictures aren't expected like billing and dispatch notes.

Laser Printers originated in the 1970s but machines with a relatively low purchase cost were first available in 1984. Apple's LaserWriter from 1985 with 1.5 megabytes of memory, PostScript language and 300 dpi resolution would still make a good correspondence printer. At the time 1.5 megabytes of memory was a lot and made laser printers expensive. Laser printers need a lot of memory because the page image has to be "rasterised" ready to use before the printer starts. An A4 page printed bi-level black and white at 300 dpi (11.5 x 300 x 8 x 300) needs a megabyte of memory.

Laser printer resolution increased to 600 dpi with introduction of the LJ-4. In principle a bi-level image might need 4 megabytes but at the time that wasn't affordable so printers shipped with half that amount and expansion slots to allow memory to be expanded. To provide 1200dpi resolution the potential memory demand quadruples again to 16MB. The LaserJet 4000 offered this in 1998 but slowed down to half speed - that tradeoff was once common with laser printers but is no longer needed. Laser printers can have true engine resolutions beyond 1200 dpi

Laser printers work slowly when they are running short of memory. The raster image is full of whitespace so it is highly compressible; printer rasterisation software attempts to fit image to memory in various ways and when it runs short of memory it rarely gives a straight-forward error.

Inkjet printers generally use the PC they are connected to create the page image. Some laser printers using "GDI" principles do something similar.

Paper Handling: | |

A lot of traditional standards apply to paper. Records kept in ring binders, or a report printed on cut-sheets and stapled in the corner have been industry-standard for a century. Many standards were established by typewriters and filing cabinets in the 1890's and refined by inventions like Melvin Dewey's card indexes, Rand Kardex and the Rolodex. Outside a computer, the most popular way to hold information is as a book.

Paper records have a great many merits. For instance it is often much quicker to have a paper record to hand and easier to make a note about some exception on paper than it is on a computer record. Paper has properties sometimes called affordances

that make a dogeared catalog fall open at the right place or allow an urgent message on an errant purchase order![]() .

.

People like cut-sheet paper, which stacks neatly in vertical files and ring binders. Cut-sheet paper can be difficult to move in a regular fashion through a machine.

Standards like pre-cut sheet paper are a problem for printer designers and perhaps even more so for field service and support technicians.

Paper is generally thin and light, but also bends, crumples and tears quite easily. Common papers vary from 60 gsm copy paper to 120 gsm letterhead bond and finishes vary from polished and waterjet cut to handmade and ragged. Some of the varieties of paper people may like are not going to pass easily through a machine.

Continuous Stationery

Reliable paper movement is best guaranteed using continual stationery on a roll or fanfold

stack. Ticket machines and label printers tend to work like this.

For extra reliability take away the paper's freedom to move in any other way by putting sprocket-holes down the side. This is the mechanism used with photographic film. Paper has 5/32nd inch holes (4mm) at half inch intervals (13.7mm) as a standard. Tractor feed paper tends to be available in two sizes, 15 inch by 11 inch and 9.5 inch by 11 inch (381x279 mm and 241x279mm). The wide paper is often printed with green lines which help the readers eyes maintain continuity along a line. The formats are time honoured, they originated with IBM printing tabulators in the 1920s.

The problem with fanfold tractor feed paper is simply that people don't like it much. It gained a user base in the 1980s and '90s when dot matrix printers were commonplace and it was perceived as modern. Then laser printers made plain cut sheets more common and inkjet printers followed that trend. Cut-sheet paper feed is now sufficiently reliable to make tractor feed an unusual requirement used in fast printers running largely unattended ![]() .

.

Dot matrix printers often still use tractor feed - its partly tradition and it also contributes to reliability. There are few laser printers with continuous feed tractors, it tends to be the preserve of machines like the InfoPrint or Microplex series.

Roll Feed

Large printers like HP's Designjet

series use roll-feed, partly for reliability and because sheets of A1 or A0 paper are rather inconvenient in an office space. Very large sheets are rarely fed from a tray - the sheet is just too large to be picked up by rollers and the floor-space taken up by an input and output tray would be too great.

Point of sale printers used in supermarkets and label printers used in logistics also use roll feed. Roll feed gives reliability. Printers are typically thermal and very simple, the only drive roller is often the platen itself. The printers are often very easy to reload, just a matter of dropping a new roll of paper in and extending the first label out of the print station.

Cut Sheet Paper

Automatic cut sheet feeding dates back to the 1980s. Rutishauser used to make cut-sheet feeders for Diablo daisy-wheel printers which were otherwise loaded by hand - as typewriters had been for a century. The Apple ImageWriter had a sheet-feeder as well. Neither was reliable.

Laser print was intended from the outset to be correspondence quality

. Early laser printers were quite expensive - $2995 for an HP LaserJet and $6995 for an Apple LaserWriter. There are implications that the printed material carries some prestige, is somehow personalised, was thought through, that it wouldn't have been too much trouble for someone to load paper into the typewriter.

Paper Feed

It would be far too much trouble to load paper into a laser printer of course. At 8 pages per minute it would also be a full time job.

Early paper feed mechanisms often relied on black rubber rollers that were hard to the touch, intended to last. To get reliable paper feed the main change has been towards softer rollers. Paper pickup rollers usually have a soft rubber coat with a textured surface which is intended to grip the flock or surface texture of the paper to push it through the printer.

In a laser printer, paper movement is often driven from the main motor cog chain via a clutch. In a typical arrangement this turns a D

shaped roller through one turn, where the roller disengages from the paper after half a turn or less. The paper should now have been pushed forward to a registration station

which is usually a long hard rubber roller mated with a long steel roller. Paper is pushed into the nip between them.

Just before the registration rollers there is a paper sensor that will trigger when a sheet arrives. If the roller turns but the sensor doesn't trigger at the correct time the printer's engine control microprocessor will report a paper feed error. On an HP printer the paper feed error numbers begin 13

![]() .

.

If paper won't feed properly check the tray paper guides first (see below). Then check for jammed labels and paper swarf, and make sure the paper detector switches move correctly (if you can spot where they are). After that suspect the paper pickup and feed rollers ![]() .

.

The pickup rollers in modern printers are not intended to last forever. If the printer is old the roller rubber may have aged and stiffened. If the roller has been heavily used it's texture will have worn away. Pick rollers are often matched by separation pads in the body of the tray or by a separation roller and they wear as well. It is normal to replace both the pickup and separation device at the same time.

Small printers operating at low speed often have a single feed roller and pad which push the page to the registration station - the point where printing begins.

Larger printers may have additional feed rollers for each tray. Fast printers tend to use a pickup roller, a separation roller which idles gently the opposite way and a feed roller.

Paper crumpling as it feeds can be caused by unevenly worn feed rollers pushing it towards one side

In recent times most professional

printers have used soft rubber rollers but have made them fairly easy to replace. That isn't always true for cheap printers where the manufacturer may have thought the whole printer would be treated as a disposable item. Cheap printers can be annoyingly the most difficult to repair.

Paper Trays: | |

The cut sheet paper feed mechanisms used in modern printers have their origins in inventions dating back to the 1940s and refined in photocopiers during the 1970s. The general idea is to put a small stack of paper in a tray, hold the tray up against a feed roller using a spring and turn the feed roller at an appropriate time until paper arrives at some registration station rollers or a platen. At this point the paper feed roller usually disengages allowing the registration rollers to push the paper through the machine.

It sounds simple, but cut sheet feed for low cost printers only became reliable in the 1980s and is still sometimes a source of problems. Poor quality paper (damp or with badly guillotined edges) and worn feed rollers commonly cause misfeeds.

In principle any kind of printer might take any sort of feed mechanism, but that isn't how things are in practice. Laser and inkjet printers almost invariably have cut-sheet feeders, whilst most dot matrix printers have forms tractors for continual forms and thermal printers are roll fed.

The average small printer has two paper sources:

- A main tray built into the printer body, often sliding into the base.This might be called a

cassette

. - A multi-purpose tray that folds down at the front of the printer and takes a few envelopes or several sheets of paper such as letterhead. On low cost printers this might be missing, or a

priority slot

to feed one letterhead or envelope might take it's place.

A priority slot is a modification to an existing tray which allows one item of stationery to be pushed on top of the stack of paper in the tray, but handled by the same feed rollers. It servers the same function as a multi-purpose tray but isn't as flexible and requires the person using the printer to be next to it.

Multi-purpose trays normally fold down on the front of the printer and use a slightly different feed path with it's own feed roller and separation pad to present paper to the registration station. Typically a multi-purpose tray might hold up to 150 sheets of paper - some transparencies or about 10 envelopes. Envelopes are difficult to feed because they are made from two layers of paper. Very often there is a nearly straight through path from a laser printer's multipurpose tray to the rear face-up paper flap - this route will handle heavier media than the main tray.

As well as their useful roll handling labels, envelopes, transparencies, and other odd media the multi-purpose tray is also a help in testing printer feed problems. If paper will feed from the multi-purpose tray but not from the cassette that helps narrow down the fault.

Low Cost Paper Feed

Paper feed mechanisms vary in sophistication. In some inkjets just one motor is used for both carriage motion and paper feed, running in different directions for the two jobs and using the print carriage being at the left to engage a clutch and pick up paper (HP Deskjets did this). Most older and low cost laser printers have a drive-chain driven by a main motor with a solenoid operated cam or a clutch to operate the feed rollers. Many older cut-sheet feeder designs rely on gravity a bit to keep the bottoms of the sheets aligned and reduce the power needed by the feed process.

Printers intended for domestic use often have a tray with a maximum capacity of 150 sheets of paper. Whilst that is adequate for home use it can be annoying in business, particularly if the printer is shared on a network. Shared printers typically have a cassette holding 250 sheets so that a large part of a ream of paper can be emptied into them at once. The bigger and more office-oriented the printer the bigger the paper tray capacity.

Power Lift

There is often a design step-change between machines with 250 sheet and those with 500 sheet cassettes. In the lighter design the weight of paper can be held up against the feed roller by a spring. The greater weight of paper in a 500 sheet cassette usually implies there will be a motorised cog-driven power lifter which hauls the paper stack up toward the roller. the power lifter can keep the pressure on the feed rollers just about constant, reducing the probability of misfeeds.

Printers designed for serious office use can often take a tower

of paper feed options, two or more additional trays including one holding up to 2,000 sheets. the large capacity tray will often let the printer run without operator attention for several days, which is useful for large shared machines like multifunction copiers. Printers like this usually have a base including castors so the whole thing can be free-standing.

Most recent laser printers send printed paper to an output bin on top of the machine by default, typically holding 250 sheets. There is usually a paper detector which will stop printing when more than 250 sheets have accumulated. Some printers have an offsetter which can push each print job to one side of the bin or the other so that it is easy to distinguish between print jobs. Printers intended for office sharing often have the option of an output stacker which can send different pages or different jobs to separate output bins.

Tray Terminology

Unfortunately there is no standard terminology for paper trays. HP usually provide two trays on all but their cheapest laser printers, the multipurpose tray is often called an MP

tray" but is tray 1 in the printer driver dialogues. The cassette

slides into the printer, usually in it's base and it tray 2

. Any subsequent trays become tray 3, 4 or 5.

If you ask for a tray for an HP printer that is likely to be interpreted as both the tray and its housing - a whole accessory tray. HP normally call the thing paper drops into a cassette. In the US where paper sizes are less standard it is common for businesses to have two or three cassettes so that they can swap paper sizes easily. In the UK and Europe that is unusual - we tend to use A4 for everything.

Brother call the fold-down tray "MP" but don't give it a number, the cassette is tray 1. Lexmark call the optional assembly for extra paper a drawer

but the spare doesn't come with the tray/cassette in it.

Beware when dealing with extra trays. It is very easy to order a cassette in mistake for a paper feed unit, a 500 sheet cassette instead of a 250 sheet one and so forth. Use diagrams, pictures and part-numbers where possible. These parts are not common items and ordering the wrong thing will cause consternation. Suppliers will not take items back once the parcel has been opened because their suppliers and the manufacturer will not.

It is usually preferable to order extra trays and duplex units with the printer. Optional trays, duplex units and output stackers are usually much cheaper bought with the printer.

Duplex: | |

Duplex means printing both sides of the page. Most printers can print on both sides of a page if someone turns it over and re-inserts it in the machine but that means someone standing over the printer. Auto-duplex units take a page as it moves to output and re-inserts it at the input the other way up. Adding duplex to a printer adds a certain level of mechanical complexity, the duplex unit typically has several opto-detectors and rollers.

Duplex printing was almost unknown in the 1990s, a few machines like the HP-4Si had it as an option. Duplex is now commonplace and sometimes adds very little to the purchase price of a printer.

A point to watch out for is that duplexing can significantly slow some printers down. Rather than the next page being a flick of the feed-roller away it has to make a return journey from the fuser to the registration station, and probably be reversed at some point.

Duplex print tends to look more professional - more what is expected of a printed booklet. Duplex printing reduces paper use and will save both money - and trees.

| | Optional Paper Handling: | |

One of the measures of a printer is the range of optional accessories it can take. A big-office system has a fairly simple print-engine at its core but it sits in a nest of options -a multi-function scanner, paper input devices, output stackers, collators and booklet makers.

Options for paper handling usually include:

- - a variety of input trays, ideally users might have a tray for every paper type they are likely to use.

- - a duplex unit - built in on some recent printers.

- - output trays and finishers. Stackers, collators, hole punches, stapler-stackers and saddle-stitch finishers to group and bind documents.

Printers shipped with a duplexer, an extra tray and a network connection designed for office use are commonly called "DTN" models. So the Color LaserJet 3600 DTN has an extra tray, duplexer and built in networking.

HP got bored with this simple and memorable naming system so they decided to use the suffix "x" for "extra" as the name for the emergent standard with duplex, an extra tray and a network connection ![]() .

.

Maximum Capacity: | |

Maximum capacity is the grand total paper capacity from all the input trays in the maximum configuration. If there can be up to 4 x 500 page trays and a 100 sheet multipurpose tray that's 2,100 pages. For larger printers and copiers the maximum capacity figure is a surprisingly good measure of printer size and capabilities.

Processor: |

The following four sections on printer processors, memory, interfaces and print languages are all quite strongly interconnected.

A printer is made by its hardware; the motors, sensors, rollers, printhead and ink supply. Printer hardware could be entirely controlled by a nearby computer. That was done in the past and still is with low-cost inkjets, for instance those using the LIDIL print-protocol ![]() . Every recent printer has a processor of some kind. How much processor power a printer needs depends on the technology used - home inkjets print relatively slowly and rely heavily on a nearby computer. Wide-body printers and laser printers often need their own computing power.

. Every recent printer has a processor of some kind. How much processor power a printer needs depends on the technology used - home inkjets print relatively slowly and rely heavily on a nearby computer. Wide-body printers and laser printers often need their own computing power.

Memory: |

Printers need memory to make up the raster image of a printed page. Most recent print technologies make up pages from a large number of dots. The pattern of dots are usually held as a bitmap sometimes called a raster

in the printer's memory. Even a dot matrix printer needs it's own local memory ![]() .

.

| | Interface: |

Interfaces are the connection between the printer and the computer(s) it serves. Modern printers almost invariably have a USB port and printers intended for sharing usually have a network port as well.![]()

USB ports should be very easy to use because the interface standard is plug and play. Plug the printer in and the system should identify it, install drivers and offer to work. USB interfaces were defined in the mid 1990s but not widely used until 2000. Older operating systems did not support them well so printers went on using the Parallel or IEEE 1284 port (which should be plug & play as well - but may not be on very old PCs).

Recent printers support USB 2.0 but until recently it was common to find a slower USB 1.0 port. It might seem evident that transferring a million pixels to a page requires a fast connection but in most cases the computer is sending a print language and the printer is building the page image from that so a fast interconnection was not that important.

One nice thing about USB is that the computer will detect the printer and install it automatically. When a USB device connects the USB drivers in the computer detect an event and exchange messages including a number which uniquely identify the new device

With a network this might happen via the Zeroconf protocol but most printers need some setting up.

Network: |

Network printing makes sharing a printer easy without slowing down one of the PCs. Printers with network ports have been around for a long time but have recently become commonplace. Today's networking standard Ethernetwas invented as a way to share printers. A problem with Ethernet is that the frame structure is quite complicated. Although there are print standards that run purely over the link-layer it is more normal to use one of the TCP/IP print suites.

A printer network interface is a print server handling the Ethernet frames, TCP/IP stack and a print protocol such as LPR or IPP. To put it another way the print interface is a small, semi-independent computer with it's own firmware and 16MB RAM - which used to be quite expensive.

Printers designed to be shared, those intended for businesses, now often come with a wired network port "embedded" or built into the formatter board.

One of the advantages of having at least a basic LCD display on the control panel is that the IP address can be set up manually. If the printer IP address is configured by DHCP then the server (probably a nearby router) should be told to allocate a persistent address to the printer - bind the printers MAC address to a single IP address.

Network Protocols: |

Network protocols are the conventions data needs to follow to be understood by the various machines on a network. A basic assumption these days is that the network will be Ethernet and the information will find it's way using the TCP/IP protocol - in other words every PC and printer needs an "IP address" and "netmask".

Several print protocols have been invented over time; Microsoft Windows used to use the "SMB" protocol. Unix and Novell can use LPD and people probably ought to use IPP - Internet Printing Protocol - which integrates with authentication and secure sockets. In practice people tend to use JetDirect Port 9100 printing or "raw" print where the printer simply listens for a print connection and then prints it; it isn't sophisticated but it works.

Print Languages: |

Print languages or page description languages are the way in which the layout of the page is specified and transmitted from the computer to the printer. There are several ways this can be done, as a bitmap, as vectors, as text or as other kinds of graphic primitives.

Many printers will actually print plain text with no print language except the ASCII code. Old DOS and command line Unix often work this way but the complete absence of fonts and graphics limits the appeal.

Bitmaps can have a substantial memory footprint although it is possible for the printer drivers to compress what they send using techniques similar to those used to produce gifs and jpegs. The printer will then need to decompress the image on the fly as it produces the page.

Low cost printers often use "host based" print techniques. These printers are often intended for Microsoft Windows only because they use the computer processor and driver to make up the page from the Windows Graphics Device Interface. The computer driver makes a bitmap image and transmits this to the printer. As a result the computer processor and memory are rather busier than they would be with a conventional print language. To put it another way, the burden of printing falls on the user's computing. Given the power and memory capacity of a lot of recent PCs this may not be very noticeable.

Adobe's invention of the PostScript language and HP's invention of PCL and HP-GL/2 are substantial underlying reasons for the success of those companies. They are both essentially vector languages as is CALS G4. The computer sends instructions and coordinates to draw the required shapes. The languages can include job control specifications as to which tray a page is to come from or whether the resulting printing will be stapled. Alternatively there may be another Print Job Language which controls such things.

PostScript is a requirement in professional graphics work because the page output will look pretty much the same on every machine. Adobe originated the PostScript language although there are several 3rd party implementations of it and these are common. Some in the design community will insist on an Adobe implementation to ensure compatibility.

Note that in ordinary printing PostScript tends to use more memory than PCL. If a document won't print or takes excessive time when using PostScript try using the PCL driver. With recent printers all that needs to be done is to change the Windows driver - printers will often auto-detect the language. Very old printers may need the language to be explicitly set.

Many printers now support direct PDF printing. This is potentially useful for printing from a computer but primarily intended to allow printing from USB Pens. A PDF is a compressed form of PostScript and is widely used for distribution of documents on the web and by some kins of e-reader.

XPS is the Open XML Paper Specification, a format for electronic paper. It was developed by Global Graphics for Microsoft but is an open standard as ECMA-388.

HP recently introduced "Smart Install". A Windows computer detects the printer as a USB pen drive and autoplay finds a file called SISetup.exe which is run to set up the basic printer driver in a couple of minutes. The method works across the network as well.

System Compatibility: |

System compatibility is largely a matter of having a computer able to match the print language(s) expected by the printer.

Printer makers naturally aim their products at Microsoft Windows users because that meets the needs of 90% of the market. Most manufacturers also provide drivers for Apple Mac systems because although they represent only a few percent of the market they are highly influential - Apple has retained terrific loyalty amongst the design community. Linux use to be less well supported but modern Linux's tend to come with CUPS (Common Unix Print System) which supports a huge range of printers and HPLIP (HP Linux Printing and Imaging System) which may provide better support for HP's own machines and gives some support for multifunction devices with scanners and faxes.

If a device doesn't have a specific driver then it will often emulate one of the HP printers. Emulation is a time-honoured tradition in print languages. Since something like half of all laser printers are HP models they are naturally the ones to emulate. PostScript should also work with any printer.

Power: |

Power for printers naturally comes from the local mains, there are just a few printers with battery supply. There is a clear division in power requirements between:

- - laser printers which invariably plug directly into the mains supply because they have a high peak consumption when the fuser heats up a page. Laser printers come in US / Japan and Rest of the World models and the internal configuration can't easily be changed. Don't plug laser printers into a UPS without being sure it can supply several kilowatts. Modern fusers come to temperature in a few seconds and to do that they draw a couple of kilowatts momentarily. Most UPSs can't meet the demand and the voltage and frequency are likely to go wildly out of spec. The printer is likely to behave oddly and give spurious error messages.

- - inkjets which have a much lower peak to scan the page and run the printheads. Inkjets often use little power bricks like those for notebook computers to make low voltage DC for the printer.

In principle inkjets could run from battery supplies like the 12 volt system in a car or boat. In practice a lot of them use 24 or 32 volts for the motors.

Most inkjet printers can run from a UPS, they typically consume about 30 to 50 watts

Power Consumption: | |

Power Consumption ranges from about 1 watt for an inkjet or small laser printer on standby to about 2 kilowatts for a big multifunction laser printer producing 60 pages per minute.

Laser printers tend to use more power than inkjet printers. When a laser printer is working the temperature of the whole page has to be momentarily raised to about 150 centigrade to melt the toner and on a fast printer heating 60 pages in a minute takes about a kilowatt of power. The fuser may actually pulse on and off, drawing 2 kilowatts or more momentarily.

Most printers are inactive most of the time and their standby power could fall to a very low level. One problem is to make a fuser that can move from cold to working temperature in seconds - HP and Canon have instant-on fusers some other manufacturers do not.

Annoyingly many printers no longer have an actual "off" switch, they have an off button which tells a control processor to shut down all the main power consuming components. The actual standby use might be anywhere from 0.1 watts to 20 watts.

Environment: | |

Two rather distinct things might be considered under this heading

- The environment the printer requires to work properly

- The impact the printer has on the environment.

Most modern electronic equipment is designed to work alongside humans. The days when computers needed specially cooled rooms have largely departed - although the reliability of a server may well be enhanced by giving it cool clean air.

Military electronics is usually designed to allow colder conditions than ordinary consumer electronics. Much below freezing plastics get brittle, wires might snap and lubricants will not flow correctly. Very cold air is usually dry.

At too high a temperature plastics turn soft and lubricants may lose their effect.

Excessively dry air allows static to build up. Electronic chips contain circuits that are literally just a few atoms thick so a static discharge will destroy them. Circuits are protected against static, but the static protection itself degrades with overuse. On the other hand condensation or direct wetness produces an electrical short-circuit. If an electronic device moves from a cold to a warm place it is common for condensation to form on it and it should not be used until it has warmed through.

Laser printers are electrostatic by nature. High voltages transfer toner from developer to drum and drum to paper. Excessively dry or damp air throw the process off. Colour printers usually incorporate a hygrometer; if the environment is unacceptable the printer will suspend operation.

Printers move small particles or droplets across a gap onto the paper. Their main enemy is excessive dust which will build up in unexpected places and cause problems.

Electronic devices need the right environment to work. Pushed too far away from the intended design environment printers won't work properly.

- The general presumption is that the operating environment is a normal office, the temperature is about 20 centigrade and the humidity around 60%

- Printers need to be upright to work properly. In principle both the electrostatic forces used in laser printers and the mechanical forces in inkjets could work any way up but the ink and toner reservoirs assume the printer is the right way up.

- Printers are assumed to be on a flat, strong surface. The printer chassis may flex a bit if it is not on a sufficiently strong table.

- Vibrations can interfere with the print process. Printers aren't assumed to be working in vehicles such as trucks or boats. Some printers can be used this way, but it definitely needs a bit of research.

- Very bright light can cause issues, penetrating the plastic case and interfering with sensors.

If you want a printer that will work in a boat with its engines pounding whilst waves roll it over try a thermal printer. There are thermal printers that can be built into bulkheads, so flying off the table won't be an issue either.

Impact on the Environment

Printers have several obvious impacts on the environment:

- Printers obviously have a manufacturing cost and impact. The bulk of most printers is plastic, there is often a metal sub-chassis and always some metal plate to reduce electrical emissions and act as guides, bearings and shafts. The electronic part of the printer is small compared with a PC.

- The most obvious environmental impact of a printer will usually be consumption of paper. Even a small 2,000 page cartridge will last through 4 reams of paper weighing 10 kilograms

- Cartridges consumed will also exceed the bulk of the printer over it's lifetime, and quite often within a year or so. Bigger, more expensive printers tend to use cartridges with much higher capacities so the waste is lower. There are substantial industries rescuing and recycling cartridges and many manufacturers have their own recycling schemes.

- Electric power is also used. Laser printers use substantially more power than inkjets in the printing process as they fuse the toner to the page with heat. The benefit is that a laser-printed page will survive handling, raindrops and even a coffee spill and remain legible, where an inkjet printed page would be washed away. Most printers are idle most of the time, but the power is left turned on. Standby consumption ranges from less than a watt through to 15 watts (more than an energy saving light-bulb)

- Printers do give off some emissions. Historically there was a concern about ozone and some big copiers were housed in separate rooms with powerful ventilation. Many early laser printers often gave off some ozone. One benefit of the smaller toner particles used for higher resolution printing is reduced transfer voltages and negligible ozone production. A problem is that those very fine toner particles tend to become airborne and circulate into office air. The impact might be similar to breathing smoke or diesel fumes in a city. Inkjets are not completely blameless, some ink droplets do become airborne.

- Printers are rarely silent. Impact printers like dot matrix machines make most noise. With a laser printer it is only the paper handling that has to make a noise. Inkjet printers add the vibration of the printhead movement. Thermal printers are most nearly noiseless, the only sound is from the paper feed mechanism.

Screen versus Paper

Printing might not seem environmentally benign but then neither are screens.

Suppose you have a pricelist of 50 items that changes once a day - is it better to display it on an LCD screen and have it ready to hand or to print it. A typical older-generation LCD screen will use 50 watts continually during an 8 hour day so 400 watt-hours - or about 5p worth of electricity and a piece of capital equipment worth perhaps £80 - so lets say over its lifetime 10p per day. (I'm rather ignoring the price of the computer to drive the screen, one computer can drive several screens - and we could use a digital picture frame).

Printing it will consume 0.5 p worth of paper, 1p worth of toner and 1p worth of fuser life (but more in inkjet ink) Of course the printer is capital equipment and uses energy as well so if printing the price list is it's sole job the screen is better value. Otherwise the print job is less than half the price of displaying the list on a screen. In the UK the probability that the paper will be recycled is better than 50/50.

Economics seem to be changing in favour of screens. LCD backlighting makes screens markedly less power hungry than the cold-cathode type that have been widespread. Most of the cost of screen display is backlighting, and electronic paper does not need that.

Actually making screens involves a couple of sheets of glass and a cocktail of chemicals to mask thin film transistors onto them, together with some cholesteric chemicals that actually makes up the LCD. The lifetime of screens once made is uncertain. the little screens used in mobile phones have a life of just 2 years or so in the UK and US but are often "refurbished" and re-used in China, Africa and India so that might give them a considerably better environmental performance. Bigger flat screens are likely to have a service life of about 5 years - comparable with the life of the computers they shipped with. In some ways they (and the computers) are dubious even as gifts for developing countries because their energy consumption is quite high compared to new equipment.

Papermakers have a history as bad environmental neighbours but many of them have cleaned up their performance so that water courses are no longer polluted, black liquor is either used for chemical feedstock or burned for energy and the main power for mills increasingly comes from waste timber and bark.

Ink is traditionally carbon-black. Carbon black plants have not usually been popular neighbours - basically they are factories deliberately set up to make soot and into the 1980s some of it tended to escape. The carbon black itself should be harmless but some of the organo-carbon contaminants might be carcinogenic if they escaped as air or water pollution.

The main environmental defect with printing is probably the plastic material consumed as cartridges. A printer will consume for or five times its own eight in cartridges during its life. Printer manufacturers take various measures to get the cartridges returned to them for recycling - partly because it's an environmental good to do so and partly because they want to deny a source of material to other recyclers.

Printers and cartridges probably do have to be manufactured in global factories. Service and recycling would make better environmental sense done locally. Printer makers don't seem to like the idea of cartridge recycling being done locally.

Printer makers are all global companies with corporate social responsibility statements and sustainability reports. They choose different aspects to stress. They are all roughly as bad when it comes to a fondness for cartridges.

Dimensions: |

Dimensions of a printer are rarely critical although some industrial machines and yachts have special recesses to hold a specific model of printer.

Most people would prefer a significantly smaller printer over a larger one if all other things were equal. Recent printers do tend to be smaller than their predecessors and that partly reflects improved techniques - and use of smaller cartridges.

There isn't a standard form factor for printers. Computers are often designed to fit 19 inch rack (and historically 22 inch) but printers usually don't seem to be built with any thought other than manufacturing convenience. This is a nuisance because quite a few printers are used in things like machine control, photo-booths and industrial record keeping and mounting the printer in the chassis isn't easy.

Manufacturers don't generally make printers large to no purpose. Fast A3 colour laser printers are big because there are four laser printer mechanisms in one box and the paper path needs to be the width for A4 and half again. Rollers in a laser printer could be pencil-thin and that would make a small laser printer. Unfortunately such printers tend to have consumables with a short life - the life of drum surfaces tends to be proportionate to their area.

The smallest printers are thermal - the printhead is just a bar of ceramic, the feed rollers are immediately behind it and the bulk of the printer is usually just occupied by the paper roll. Some portable photo printers work this way, the alternative being an inkjet.

Remember that the dimensions of the space a printer needs to be used in may be considerably larger than the printer itself. Most laser printers need at least 6 inches on every side for ventilation, inkjets may need less. Most printers also need access to the front for the trays, the back for a straight-through tray and to clear paper jams and possibly to hatches in the side for power switches.

Weight: |

Weight is also rarely a critical factor. There are portable printers which weigh about the same as an average notebook computer - not something to be carried continually in a rucksack or briefcase perhaps but useful in a car or hotel bedroom. Some printers are very heavy, notably the A3 laser printers and plotters. Older A3 laser printers can be expensive to deal with in field service because at least two people are needed to move them. (I write as someone with experience of a CLJ 9500 landing on my foot).

Plotters and other big special printers may need a special stand. Some of the DesignJets and other plotters can be difficult to get into a building, the sheer length of the crate makes them unwieldly. That situation is rare with printers these days.

Weight is clearly related to size. As usual, thermal printers are an exception. The most portable printers are thermal devices.

Acoustic Noise: | |

Acoustic noise from printers can be noticeable and sometimes obtrusive:

Laser printers make noise from fans - sometimes continually. Otherwise the noise is mainly the pickup and delivery rollers. The laser printer process is just a series of continually turning rollers and shouldn't be very noisy, there might be a trundling noise from the gear chain. Laser printers aren't usually very irritating.

Inkjet printers are normally silent in standby although some do run a fan partly for cooling the PSU and partly to suck any airborne droplets towards a filter. When the printer is running there are all the paper pickup noises. Inkjets can be rather noisier than laser printers because the vibration and noise as the carriage shuffles back and forth to perform the printing can be rather irritating. Inkjets sometimes use rather odd little mechanisms to drive paper pickup using the carriage motor. The HP Deskjets 500 series did this, forcing the head left to engage a clutch that fed a sheet of paper and saving the use of an extra motor. It was clever, but often sounded like the bit of plastic that did the job was about to snap. Sometimes it did snap !

Dot matrix printers are inherently noisy with a frequency irritatingly towards the top mid end of human hearing.

Thermal printers may have no moving parts except the feed rollers and paper so they can be disconcertingly silent.

Consumables: |

Consumables are where money comes into printer making. Printers inevitably use some colourant like an ink or toner powder and in principle this can be supplied in lose form in bags or bottles. But: -

- inkjets use such fine nozzles that any contaminant in the ink would potentially block them. Using the wrong ink can damage a printhead that should have had a long life. Another reason for using cartridges is that the ink isn't usually hazardous but it certainly can be messy.

- laser printers use fine toner powder and any irregularity in it will damage the look of the pages. Using an imperfect toner usually wont do any long term damage although a toner with the wrong melting point certainly can wreck a fuser. Human hair and other contaminants getting into the mechanism have been known to block the waste mechanism on printers. Toner used to be potentially harmful but most manufacturers material safety data sheets say toners are not toxic.

Cartridges are almost invariably used to deliver the ink and toner for small printers. In the early days there was a lot of experimentation to find the best way of wrapping inks and toners so that they would not spill so there came to be many different families of cartridges matching printer engines.

Cartridges are proprietary, protected by various copyrights and patents. Printer manufacturers no longer depend on selling machines for an income, it is more or less guaranteed from the stream of replacement cartridges. This creates a tension:

printer makers think they are creating an ongoing relationship with their buyers - buyers who might feel ripped off by the price of new cartridges try to two-time them by refilling them.

Ideally printer buyers would carefully research the price of the printer and of all it's consumables and weigh this up against it's specification and print quality to reach a decision on what to buy. Unfortunately this doesn't work terribly well.

Inkjet cartridges

can be

Tricolour - three inks are held in one cartridge with a single shared printhead. This gives a one piece cartridge which is easy for users to change. There is usually a separate black cartridge because most of what is printed is text so black ink gets used more heavily. The bad thing with tricolour cartridges is that when one ink is exhausted there is nothing to be done with the others.

Single piece - each ink is in a separate tank with it's own integrated printhead. Thermal printheads need not be very expensive so they can be treated as disposable. This does make life easy for users - when an ink system fails it just gets entirely swapped. There is the issue that printheads are often disposed of when they are still workable but for users interested in economy this is an opportunity to mess around with re-inking at very little cost.

Separate heads - each ink has both an ink tank and a separate printhead so a colour printer has at least 8 consumable items. On average a thermal printhead will last through about four changes of ink tank. At some points the printer may warn that the head has failed and the user gets the opportunity to try cleaning the head by flushing ink through it. The strong cleaning cycle uses a lot of ink and if the head has been used for some time it probably won't work.

Piezo-electric printheads are mainly used by Epson. The Epson heads are designed to last the life of the printer

. This might be interpreted as meaning the heads last quite a long time; but when they do fail a replacement will not be cost-effective.

Laser print cartridges

can be

All-In-One- the toner, developer and drum are all enclosed in one plastic moulding. The big advantage of this is simplicity for the user, when the toner runs out most of the print subsystem is replaced as well. The issue is waste of a part used developer and drum but these components aren't particularly expensive and can be recovered and recycled. In principle all-in-one cartridges are more expensive than buying the separate parts but volume manufacturing and simple logistics might more than compensate for this.

Separate components that plug together to achieve the same functional effect. The big advantage of this is that all the components get used to their optimum level and of course they are still available for recycling when they are exhausted. One disadvantage is that the printer now has several components that users need to stock - or pay for courier delivery as needed. The printer will usually inform the user when one of the consumables is exhausted so that isn't a big problem even though a colour laser printer can have as many as 13 consumables. More difficulty arises when one of the consumables has an issue like a streak in the print and gives no warning; that means the user has to find out where the problem lies and correct it - or pay for an engineer call-out.

Drum & Developer: |

The heart of a laser printer is the photoconductive drum. In the dark the drum doesn't conduct electricity and its plastic surface can be given a strong static charge. The charged surface will attract toner powder. (or repel it, printers can work either way round). Exposed to light the drum material becomes conductive and the static charge on the local surface drains away into an underlying metal layer. Scanning with a bright source of light like a laser leaves some areas charged and others neutral. The charged areas can pick up and hold a toner powder.

The toner powder has to be presented to the drum in a thin even layer, otherwise the print will be blotchy. Developers can use another electrostatic field to do this but the approach often favoured is to use magnets. Some developers are a small vat of iron filings with a roller and magnets inside. HP and Canon often use a small proportion of iron filings mixed into the toner to act as the developer.

Image Transfer Belt: | |

A toner, developer and drum produce an image in one colour. To make a colour image a printer needs to combine the three colours cyan, magenta and yellow together with black toner into a single page image.

Image transfer belts or drums build up the image from surrounding photoconductors. Drums are generally used in carousel mechanisms where one photoconductor is used four times to build the image. Belts are often used where four photoconductors produce four successive images that need to be immediately combined into one. The transfer belt can also be called an electrostatic transfer belt (ETB) and is often a photoconductive material. Whatever technique the belt uses it should be kept clean and if it seems to be unduly scuffed that could be the cause of marks on printed pages. ETBs usually have a life of something like 100,000 pages.

Fuser: |

Laser printers make an image on the page using dry toner powder. The fuser is the final stage in the process. Fusers use heat and pressure to adhere the toner powder onto the page.

The fuser mechanism is basically a pair of rollers:

- The heated roller is often a metal tube heated by a lamp to a temperature over 100°C to soften the toner, this needs a surface which is non stick to both paper and toner. Some printers use a ceramic heater and a foil instead of this roller.

- The pressure roller is usually made of silicone rubber and held by springs against the heated roller to provide the pressure.

Fusers ultimately wear out as continual contact with paper and toner gradually degrades the non stick surface. Sometimes the heater fails and sometimes the non-stick material falls to bits.

Fuser Life Expired

Printers invariably keep a count of how many pages they have produced and indeed of how heavy the toner use was and they compare the figure with a target that means the fuser has reached the end of it's life. Printers may simply give a persistent message, or they may give a message for a while then ultimately stop.

Dirty Pages

When the fuser has aged beyond its best pages start to look smudged and dirty because toner is building up on the rollers. The dirty appearance of the pages commonly starts intermittently at the sides of the page (edgewear ![]() ) and gets progressively worse.

) and gets progressively worse.

Marked Pages

Fusers can also fail suddenly when the non-stick surface comes away from the rollers. This will leave a mark the shape of the damage at regular intervals down the page. Confirmation of the fault is a matter of taking the fuser out and having a look at the rollers, rotating the cog by hand if necessary.

Printer Stops