| | Laser Printers |  |  |  |  | |

Laser printers are popular in business so they account for the greatest amount of printing. They are reliable and easy to use. As well as policy documents, reports and correspondence the bulk of printing is made up of purchase orders, delivery notes, invoices, remittance advice and so forth:the business process. A lot of this paperwork is done with mono laser printers.

The laser print process might better be called "electrophotography".The image is created on a photoconductor which is a material that becomes conductive on exposure to light. The photoconductor is usually a coating called "OPC" coated on a drum.

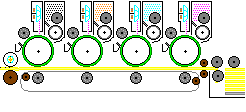

As the drum turns it does most of the work of the printer. OPC (Organic Photo Conductor) is first charged up with a static electric field. This is sometimes done with a charge roller and sometimes as suggested here by a corotron wire. The OPC is then exposed to the light and dark of an image. Where the photoconductor is lit the static dissipates leaving a latent image made from different charges.

The drum rotates next to the developer. The developer roller carries a fine coat of toner powder which is attracted to areas of the drum with a static charge creating a visible image.

Meanwhile a sheet of paper has been ejected from the tray by the pickup roller and is being fed under the drum by the registration rollers.

The image can be transferred from drum to paper by putting another strong static field under the page, pulling the toner away from the drum. Most printers don't quite pull all of the toner away - any remaining toner is scraped off with a blade and the static is fully discharged with an eraser lamp; the drum is ready to be used again.

The image on paper is still made from loose toner powder. In a final stage the page goes between hot rollers called a fuser which stick the toner material to the page.

Laser & Photocopier

Today's use of laser printers reflect their origins. Laser printers were meant as office machines and have largely remained so.

Laser printers were originally based on photocopiers. Chester Carlson invented the Xerographic copier and his patents were the basis of the Xerox companies fortune. Xerox copiers were introduced on a large sacle in the late 1950s. The concepts behind the copier were complicated, the machines were expensive and usually placed on lease. Government departments might have one or two on site.The main alternatives were carbon paper and the Gestetner and Roneo wax stencil duplicators.

In a photocopier the image given to the photoconductor comes from a brightly lit sheet of paper via a set of lenses and mirrors.

Laser Origins

The first laser printer was constructed at Xerox PARC in 1969 by Gary Starkweather.

Xerox was a very big name in office equipment in the 1960s; second only to IBM. The Xerox Palo Alto Research Centre aimed to find ways of improving the process and new ways of using it. PARC certainly did that, inventing not just the laser printer but Ethernet as a means to share it and the kind of graphical computing we have today as a way to use it. Xerox largely failed to capitalise on these inventions - an epic failure to realise the potential of R&D.

Adding the laser scanning mechanism to a photocopier was apparently quite simple;the problem was to make up the page image. At the time microprocessors were unknown (they were invented at Intel and TI in 1970). The formatter was a DEC PDP-11/34 minicomputer, which was a moderately powerful machine at the time. Incidentally the copier was a 60 page per minute model so the very first laser printer was comparable with today's machines. A half century of technical advance has made laser printers cheaper - not faster. Laser printers were big and cost hundreds of thousands of dollars to buy; A bank head office might have one. Until very recently the computer power and memory needed to hold a page image have been a limitation.

By the late 1970s Xerox patents were expiring and a whole tribe of Japanese camera makers began to explore the idea of photocopying; Canon, Ricoh,Konica and Minolta for instance. Canon was interested in ideas such as a personal copier and they developed the all-in-one cartridge for that. In 1984 Canon developed the LBP-8 engine, the smallest and lightest laser printer made to that time. Canon were looking for technological alliances and agreed with HP, QMS and Apple to sell them engines which they would configure for their own use. This OEM use of parts made by others had become standard practice. HP was using Epson dot matrix and Olivetti daisy-wheel mechanisms for instance. Canon seem to have been primarily interested in using laser printers as high speed faxes.

Apple's Laserwriter was revolutionary: intended for graphics it needed a 1MB framebuffer and 512KB workspace for the PostScript interpreter and a fast 12MHz Motorola 68000 CPU. Such computer power was costly and drove the purchase price to US $6,995. To share the printers Apple developed it's own LocalTalk networking system. Apple Mac computers with Aldus PageMaker and the Laserwriter became the basis of the desktop publishing industry. Apple's position in the graphics industry and as a leader in design owes a lot to this.

LaserJet

HP used the LBP-8 engine in a completely different way, aiming at the word-processing market, mainly reports and correspondence. At the time there were two competitors in this market, the IBM Selectric golfball typewriter and the Diablo Daisywheel (Diablo had been taken over by Xerox).

HP's "LaserJet" printer used an 8MHz 68000 processor and just 128MB of memory together with the PCL3 language used on their dot-matrix printers. The result came in at $2,995, which was expensive but not outrageous by comparison with a daisywheel typewriter. Graphics beyond postage stamp size were beyond the LaserJet because it had too little memory. The PCs of the time weren't much better, Windows was new and not very succesful. The HP LaserJet was succesful and over four years. they sold 4 million of the LaserJet "Classic" and the LaserJet II.

HP's sales were impressive for the time. By then there was quite a lot of competition from Ricoh,DEC and Kyocera. One of HP's talents has been to marry good printer drivers and their fast, flexible PCL print language with formatter electronics that does the print job reliably.

Development

The laser printer mechanism uses a set of six or more precision made rollers driven by motors. Although the mechanism is quite complicated and needs very precise alignment once it is in motion all the actions are continual and in one direction so it can be quite fast. One limit on the speed is how fast the local processor and memory can produce the video image for the laser - that is why Apple's graphics oriented LaserWriter cost more than twice as much as HP's text oriented LaserJet.

Technical progress in laser printers has largely been to increase the speed and resolution and provide colour.

Resolution on early printers was 300 dpi. This resolution was inherited from the offset litho industry and is still often used. It gives text and diagrams that have some slight visible aliasing (a stepped effect on diagonals).

Recent laser printers have an improved resolution of 1200 dpi today. This gives fine lines for diagrams and truly eye-straining small print for contracts. More helpfully it allows dot patterns to be used as a way of giving grey-scale to photographs.Increasing the resolution has meant finer toner powder, faster lasers and better alignment of parts.

Cartridges

Historically the various parts of a copier were built into the machine, taking the drum or developer our was a job for an engineer. As copiers became more commonplace the parts that needed changing had to be made more convenient.

Cartridges can take several forms. Many manufacturers opted to have separate toner, developer, drum and waste bottle. This should be most economical, since only the parts that are worn out are changed.

The approach taken by Canon (and HP) has been to use an all-in-one cartridge like that developed for the personal copier. This has all four parts in one

Colour Print

Laser printers can be made to produce colour by using four different coloured toner powders and one photoconductor drum. The mechanism can be made quicker but more costly by having four toners, developers and drums. A colour laser printer is complicated but given a huge market even something this complicated can be made economically. The printer manufacturer has a captive market for print cartridges.

A colour printer typically uses four drums, each with precharge,developer and cleaner. The single transfer roller is replaced by a transfer belt and four transfer rollers. The difficulty with colour is the sheer complexity of a nearly 20 precision made and aligned rollers. There are also about a dozen high voltages to work the different transfer stages - one side of a typical printer is often taken up with the high voltage power supply.

Colour printers tend to do a rather different job to mono printers.Mono printers tend to be used for the business process - correspondence and invoices. Colour printers can do those things but they also provide attractive publicity information in low volumes.

It is possible to run off an individual colour catalogue where conventional printing requires orders in thousands.

Colour laser printers may be expensive to make and run but they may be cheaper and more economical than the alternative of long print runs for brochures and catalogues.

Copyright G Huskinson & MindMachine Associates Ltd 2012