Brother Original Toners

Fuser and Drum

Spares

Brother HL 5200 Series Printers

Brother's HL-5200 series comprises the HL-5240, HL5250DN, HL-5270DN and HL-5280DW Printers

The DCP-8060 and DCP-8065 and MFC-8460N, MFC-8660DN, MFC-8860DN and MFC-8870DW are closely related.

A4 / US-letter sized black and white laser printer series.

Speed is 28 pages per minute for all printers in the series.

Resolution is a true 1200 dpi, however printers are fastest at 600dpi. They will slow down to some extent at 1200 dpi and the HL-5240 may need expansion memory to make full use of the resolution.

This series of machines was launched in late 2005 and the HL-5240 in 2007.

Features:

- PCL 6 and BR-Script3 emulations as standard

- 300 Sheet standard input capacity

- 50 sheet multipurpose tray

- 250 sheet cassette under the printer

- Up to 800 sheet total capacity with two extra paper trays

- Parallel and USB.20 Interfaces on all models.

- Network on the HL-5250DN

- Wireless network on the HL-5280DW

Model Names and Part Numbers:

Printers

- HL-5240 - PCL6, BR-Script- 3 printer with 16MB RAM

- HL-5250DN - built in auto-Duplex unit, Network ready and has 32MB RAM

- HL-5250DTN, built in auto-Duplex unit, extra Tray and is Network ready and has 32MB RAM

Printers with Control Panel

- HL-5270DN, built in auto-Duplex, Ethernet, 32MB RAM, LCD Control Panel, Secure print feature.

- HL-5280DW, built in auto-Duplex, wired and wireless Ethernet. LCD Control Panel with 3 colour backlight to give an instant indication of status. Secure print capability.

Multifunction Scanner / Copier

- DCP-8060, 30ppm printer, scanner copier. Flatbed scanner optical resolution 600x2400.

- DCP-8065DN, 30ppm printer, scanner copier. Flatbed auto-duplex scanner. Ethernet. Both printers have PCL6 and BR-Script3

- MFC-8460N, Windows GDI 33.6kbFax with 40 one-touch dials

- MFC-8660DN, Mostly Asian market

- MFC-8860DN, Extended MFC-8860DN with scan to FTP, LDAP, auto duplex scanner and printer

- MFC-8870DW, As the MFC-8860DN with 802.11b/g Wireless Interface.

Scan to email requires manual input of the address. No USB memory drive support Scan a color page to PDF is slow - nearly a minute.

The HL-5300 series was introduced in April 2009 replacing the HL-5200 series. The new printers are slightly faster at 32 pages per minute. New models are the HL-5340D, HL-5370DW and HL-5370DWT.

There are two additions to the MFC-8000 series: MFC8480DN and MFC8890DW

Control:

Toner/Drum/Paper LED and 3-colour Status LED. Buttons for Go and Job Cancel.

The HL-5270DN and HL-5280DW are the same engine as the HL-5240 and 5250 but with a control panel.

The HL-5240 and HL-5250 are printers with no LCD display; without a user manual to hand it is difficult to diagnose some problems:

Some of the common LED errors for the 5240/5250 are:

- Status light green, Toner light blinking: Toner Low

- Status light out, Toner light On, : Toner out

- Status light green, Drum light blinking, : Drum life over soon

- Status light red, Paper and Toner lights: Expansion DIMM error

- Status light red, Drum and toner lights: Main PCB failed

- Status light red, Toner light: Fuser failure

Control Panel Details:

To get a status page press go three times in succession

HL-5240 / 5250

User's mode:

Power on holding "Go". All the LEDs will light

Then Status will turn off, now release Go, all the LEDs will turn off.

A subsequent series of pressing "Go" will select various tests

- 1 = Test Page

- 2 = Print Fonts

- 3 = Hex Dump

- 4

- 6 = Factory reset of the Network Adapter. All the LEDs light to indicate the network card has been reset to default.

- 9 = Test Sample

The HL-5270 / 5280 have a similar process except that Go is held until the message "User's Mode" appears on the display with an orange backlight. Release the Go button and all the LEDs should go off.

There is more on service modes below. They are required to reset consumable and maintenance counts.

Duty Cycle:

Brother dont tend to give a duty cycle figure, perhaps understandably because the figures do tend to be rather meaningless. In the Used manual neither it or an MTBF are stated. These printers are lightly built.

site-city.com/articlems13 claims a duty cycle of 20,000 pages per month for the HL-5280 and the material for their blurb presumably came from Brother in the US.

Print Speed:

Print speeds are:

- 28 pages per minute for A4 sized pages and 30ppm for letter pages

- HL-5250DN Auto Duplex Printing at up p to 13ppm

First print out in less than 8.5 seconds.

Scanner Abilities:

These printers are closely related digital copier and multifunction machines.

- DCP-8060, DCP-8065DN, MFC-8460N, MFC-8660DN, MFC-8860DN, and MFC-8870DW

Print Resolution:

Print Quality is partly determined by the size of pixels normally given in DPI. The HL-5240 and HL-5250 offer a true 1,200 dpi mode for Windows and MacOS users. However the user manual says: "If you use the high quality 1200 dpi setting (1200 1200 dpi) the print speed will be slower."

Resolution abilities depend on the operating system:

Win 95/98/Me/NT4.0/2000/XP - Up to true 1,200dpi

Mac OS - Up to true 1,200dpi

Linux - Up to 600dpi

DOS - Up to 600dpi

Paper Handling:

A4 / US letter width paper path.

Multi-Purpose Tray: 50 sheets with 80gsm paper

Paper Types: Plain paper, Bond paper, Recycled paper, Envelope, Labels, and Transparencies.

Paper Weights: 60 to 161gsm (16 to 43 lb) through manual feed tray. 60 to 105gsm (16 to 28 lb) from standard tray.

Paper Dimensions:

Width: 69.9 to 215.9mm feed tray (2.75 to 8.5 in.)

Length: 116 to 406.4 mm (4.57 to 16 in.)

Multipurpose Tray:

A multipurpose tray is standard on all models. It's a 50 sheet tray;Plain Paper, Bond Paper, Recycled Paper, Envelopes, Labels, and Transparencies

Size range: Width 69.9 - 215.9mm, Length 116 - 406.4mm. Weights 60 - 161gsm

Tray 2 & 3:

Up to 250-sheet trays type LT-5300. Optional trays take A4, Letter, B5 (ISO), A5, B6, Exe

Face Down:

Standard output to the top of the printer holds 150 sheets.

Duplex:

Two-side printing is provided with an auto-duplex unit on the HL-5250DN, 5270DN and 5280DW.Manual duplex is supported on the HL-5240.

Processor:

The combination of processor and memory in a printer determine how quickly the print language can be re-interpreted as a page layout. Where a task is undemanding such as printing pages of text there is no need for a powerful processor. Tasks such as producing a full page photograph are much more processor and memory intensive.

All these printers use a Fujitsu SPARClite 266MHz processor

Memory:

- HL-5240, 16MB Expandable to 528MB

- HL-5250DN 32MB. Expandable up to 544MB

One 144-pin DIMM slot for 64, 128, 256 or 512MB devices

The HL-5240 memory is sufficient for most ordinary purposes but the printer may reduce the resolution from 1200dpi to 600 dpi to print the most complicated graphics.

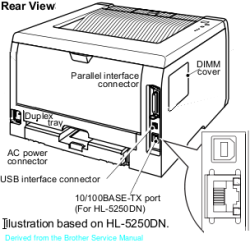

Interface:

All models have Parallel and USB ports

- USB port as standard; Hi-Speed USB 2.0

- Bidirectional parallel port to IEEE1284 standard

Network:

- 10BaseT/100BaseTX Ethernet standard on the HL-5250DN

As well as the built-in ethernet port the printers can be attached to external print servers which also support NetBEUI.

Network Protocols:

The HL-5250DN supports:

HL-5250DN ARP,RARP, BOOTP, DHCP, APIPA (Auto IP), ICMP, WINS/NetBIOS, DNS, mDNS, LPR/LPD, Port9100, IPP, SMB Print, FTP, SNMP, HTTP, TELNET, SMTP, TFTP, ICMPv6, NDP, DNS, mDNS, LPR/LPD, Port9100, IPP, FTP, SNMP, HTTP, TELNET, SMTP, TFTP

Network Management Tool

BRAdmin Professional

Web BRAdmin

Web Based Management

BRAdmin Light

Brother original Windows utility for printer and print server management.

Server Based Management Utility for Windows IIS 4.0/5.0 mode only, downloadable from http://solutions.brother.com Printer and print server management through Web browser Printer and print server management operates under Mac OS X 10.2.4 or greater.

Print Languages:

Both the HL-5240 and HL-5250DN support PCL6 and Brothers version of Postscript, IBM Proprinter XL and Epson FX-850

- PostScript 3 emulation as standard using BR-Script 3 with 66 scalable, 12 bitmap and 11 bar codes.

- PCL 6 emulation standard with 49 scalable, 12 bitmap and 11 bar codes

- IBM ProPrinter XL

- Epson FX-850

Bar Codes are: Code39, Interleaved 2 of 5, EAN-8, EAN-13, UPC-A, UPC-E, EAN-128, Codabar, FIM (US-PostNet), ISBN, Code128

System Compatability:

Operating Systems

PCL Printer Driver for Windows 95 / 98 / Me, NT4.0 / 2000 Professional/ XP Home Edition/ XP Professional

BR-Script 3 (PPD file for Windows 95 / 98 /Me, NT4.0 / 2000 Professional/ XP Home Edition/ XP Professional

Macintosh Brother Laser Driver for Mac 9.1-9.2, Mac OS X 10.2.4 or greater BR-Script 3 (PPD file for Mac 9.1- 9.2, and Mac OS X 10.2.4 or greater)

Printer Driver Functions:

N-up Printing: Condense 2, 4, 9, 16 or 25 pages into 1 page

Poster Printing: Enlarge 1 page to print over 4, 9, 16 or 25 pages

Watermark Printing

Utilities:

Interactive Help: Instructional movie for the solution when any error message appears Status Monitor

Driver Deployment Wizard: Guides you through the steps of installing a Brother network printer on a networked Windows PC

Linux GDI Printer Driver for Linux BR-Script 3 (PPD file for Linux)

Linux systems using CUPS come with drivers built in for the HL-5240, HL-5250DN and HL-5270DN using BR-Script3

Power:

USA and Canada: AC 110 to 120 V, 50/60 Hz

Europe and Australia: AC 220 to 240 V, 50/60 Hz

Power Consumption:

Printing Average 610W at 25c

Standby Average 80W at 25c

Sleep HL-5240 Average 8W at 25c

Sleep HL-5250DN Average 9W at 25c

Environment:

Has both Powersave and Toner Save features. The "D" versions are duplex which can nearly halve paper consumption.

Dimensions:

WxDxH 371 x 384 x 246mm

Weight:

HL-5240 = 9.5kg

HL-5250DN = 9.8kg

Acoustic Noise:

Noise level (Declared per ISO9296)

Sound Pressure - Printing / Standby LpAm= 53 dB (A) / LpAm= 27 dB (A)

Sound Power - Printing / Standby LWAd= 6.7 Bell (A) / LWAd= 4.3Bell (A)

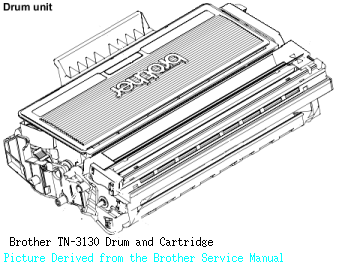

Consumables:

These printers use a separate toner cartridge and drum giving better economy than some competing machines. Fusers and roller kits are also available.

Toner

The toner cartridge clips to the top of the photoconductor cartridge.

TN-3130 Standard Yield 3,500 A4/LTR pages @ 5% coverage

TN-3170 High Yield 7,000 A4/LTR pages @ 5% coverage

TN3170 Refill Kits and separate Reset Gears can be bought to reset the "toner life end" message when a cartridge has been refilled. Naturally you will get no support from Brother themselves for doing this. At least one clone cartridge maker has a cartridge which is compatible with the HL-5030 -5070 and 5130 - 5170 series printers as well as the 5240 - 5270 series.

Printers ship with a 3,500-page starter cartridge (at 5% yield).

Brother's website warns that the Lights or LCD may go on displaying the message "Toner Life End / Replace Toner". This is normally caused by part-used toners, the printer needs to see a new toner. Clone and refill toner may give the same issue unless the reset gear is changed.

The cartridges for these printers are unusual in a few respects.

Separate Drum

The obvious point is that Brother have persisted with the idea of a separate toner and drum. This should give greater economy than having a single cartridge with both components built in. The extra issue of having two things to buy and two parts to go wrong might conflict with economy in some cases. Brothers customer base tend to be small and home offices who are more sensitive to the cost of purchasing printers and consumables than they are to the costs falling on centralised technical support.

Toner Yield

There is a choice between 3,500 page yield appropriate for small office use and 7,000 page yield which will meet the needs of larger offices and frequent users.

Brother use an unusual mechanism to inform the printer when they have been replaced. Cartridges ship with a spring loaded half-cog engaged. The cog turns and presses a couple of actuators to show the cartridge was installed and whether it was standard or high yield.

One it has been informed of the cartridge and yield the printer adjusts the bias voltage according to how much toner is left. One common technique to fix printer faults may not work as a result, swapping a part used toner from one printer into another won't cause the reset to happen and the printer will have the wrong toner level - so the fault won't properly clear and both printers might now malfunction giving over heavy print or a grey background. See Uninet imaging's PDF on refurbishing the cartridges for details. (search for TN-550 inurl:uninetimaging)

Extending the Yield

Brother cartridges are also unusual because there is no waste toner bottle. Residual toner on the drum is taken up by a blade and a charge brush in the drum assembly. The charge on the brush is changed during a cleaning cycle and residual toner is then transfered back to the developer and then into the supply hopper. As the toner gets low the printer increases the charge on the developer to compensate for the poor triboelectric properties of the toner. If cartridges are recycled and the wrong toner is used Ultimately the charge brush becomes clogged and won't take up waste toner from the drum anymore and it transfers instead to the page giving a grey background.

In fixyourownprinter.com/forums there is a lot of talk about blocking the toner sensor window on Brother cartridges with masking tape, with some people reporting they can get a thousand extra pages out of a cartridge this way. (The tape has to be used before the cartridge is actually exhausted, otherwise the printer wants to see the cog mecanism turn). A potential problem with this, as with swapping toner cartridges before they are exhausted is that the brush in the photoconductor drum gets clogged. There are also people reporting that they cleaned up the drum; however its a messy business. Home users with washable floors can get extra life out of the toners, at some risk of needing a new drum.

Regional Codes

Brother use different cartridge codes for different regions. Sometimes it is helpful to know these codes when researching information about the printer.

US cartridges are TN-550/580

EU cartridges are TN-3130/3170

Asian cartridges are TN-3145/TN-3185

Drum:

Drum:

The printer drum has a yield of 25,000 pages. The "Drum" LED will blink when the drum is near the end of it's useful life but the printer will continue to work and can be used until drum wear gives a print problem (probably faded print or streaking)

DR-3100 Drum unit 25,000 A4 / letter pages (1 page per job)

The Drum is known as DR-520 in the US. DR-3115 is the Asian version. used in the DCP8040, DCP8045D, HL5140, HL5150D, HL5150DLT, HL5170DN, HL5170DNLT, MFC8220, MFC8440, MFC8640D, MFC8840D, MFC8840DN

Drums may also be available in remanfuctured and compatible forms. As usual we warn the whilst there may be substantial savings ove manufacturers originals quality and reliability could be less certain.

Replacing the drum

Remove the drum and toner unit from the printer.

Unclip the toner from the drum by pushing the blue lock lever.

Brother tech support have taken to requiring a proof of purchase before they will help.

The following instructions were found on the Internet:

With the machine is turned on and the drum LED is blinking replace the drum unit and reseat the toner cartridge. Leave the front cover open. Press and hold the "Go" button for four seconds until all the LEDs light up. Now release the "Go" button. Close the front cover. The counter is reset and the machine should perform normally. (The instructions are the same as for the HL-5150)

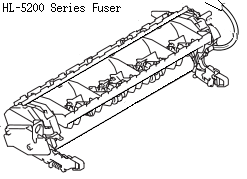

Fuser:

Laserprinter fusers adhere toner to the page using a combination of pressure and heat. Fusers fail when the non-stick surface wears out and the printer will warn of this after 100,000 pages. Fusers can fail more quickly if they are used with inappropriate toner or media.

Fuser failure is indicated by Status light red and Toner light on on the HL-5240 and 5250. (It could also be a cause of all lights flashing). Other printers in the series have LCD displays and will give an explicit message: "REPLACE FUSER".

LU0214001 110 Volt Fixing Unit (Yield 100,000 pages) aka LM6665001, LM6665001,

LU0215001 230 Volt Fixing Unit (Yield 100,000 pages)

LU0217001 230 Volt Fixing Unit / Fuser Unit UR (Yield 100,000 pages)

There are two 230 Volt fusers listed and used in the UK and EU. Both are available from UK distributors although the LU0217001 seems to be the common code.

The 110Volt fuser is normally used in the US but there may be uses in the UK such as construction sites.

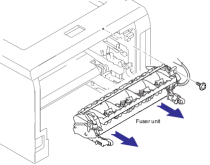

The fuser is not particularly easy to change. Details are given in the service manual but briefly:

- Power Off and Unplug the printer. Potentially live terminals will be exposed when working on the printer. Let the fuser cool before attempting towork on it.

- Remove the drum toner assembly and put them in a clean dark place.

- Remove the duplex feed assembly or the blank cover at the rear of the printer.

- Pull the paper tray completely out of the printer.

- Remove the back cover flap from its pins on either side.

- Remove the outer chute assembly by pulling at the knobs on either side.

- Remove the front and sides to get access to the fuser wiring harnesses.

- Release the heater power terminals and the termistor terminals.

- Remove the fuser screw(s) and it can be removed from the printer.

- The air filter should also be changed.

The service manual gives details and should be consulted if there is any doubt.

The fuser in the HL-5200 series printers is a conventional roller with halogen-lamp heater design. This means it takes some time to heat from a cold start but it does make it more easily repairable.

Fusers can be repaired if the parts are available.

To reset the fuser requires the printer to be put in service mode. (hold go at power on ). An outline of the Maintenance Reset procedures are given below.

Maintenance Ki:

Brother literature suggests a Maintenance Kit intended for use at 100,000 pages. There is no trace of this in the parts manual or suppliers lists. Buy a fuser and periodic maintenance parts.

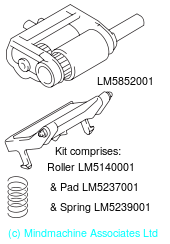

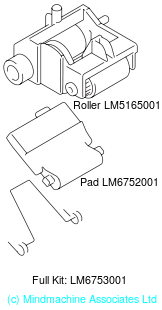

Spares:

Most spares appear to be available in February 2010. Those commonly required are:

LM6753001 - MP Paper Feed Roller Separation Pad for Periodic Maintenance. Needed when the printer gives the message "REPLACE PF KIT MP".

LM6752001 Multipurpose Separation Pad

LM5165001 1 Multipurpose Roller and Holder Assembly - double roller in holder.

LM5140001 Roller in Holder Assembly on Underside of chassis

LM5852001 - Feed Roller Assembly Separation Pad Kit for Periodic Maintenance. Needed when the printer gives the message "REPLACE PF KIT1" etc. "REPLACE PF KIT2" and "REPLACE PF KIT3" raise the same issue for trays 2 & 3 if they are fitted. They also take the LM5852001 Kit.

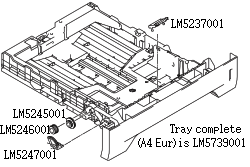

LM5237001 Separation Pad Assembly in paper cassette / tray.

LM5239001 Separation Pad Spring under the Pad

LM5739001 Paper Tray Unit (UK and European Models)

LM5247001 Lift Gear 46 - Quarter gear item labelled 1-5 on diagram.

LM5750001 Laser Unit. May be needed when the printer gives the message "REPLACE LASER".

The PCB Assemblies tend to be quite expensive and on a lead time of 7-10 days. They are sealed and not returnable once the package is opened.

LM9076001 Main PCB Assembly for the 5240

LV0119001Main PCB Assembly for the 5240L

LM9077001 Main PCB Assembly for the 5250

LM9110001 Main PCB Assembly for the 5270

LM9138001 Main PCB Assembly for the 5280DW

Changing Rollers:

Changing the roller holder assemblies involves taking out the drum assembly and putting it in a clean dark place. Pull out the paper tray and change the separation pad which is secured by hooks at either side. Put the tray to one side.

- Turn the printer upside down , the feed roller roller assembly is located underneath.

- Push the lift arm so that the pin of the roller holder disengages.

- Turn the roller holder so it rotates upright.

- Slide the roller holder assembly so it goes one way then lift and pull the other way and it should lift out.

The service manual gives details and should be consulted if there is doubt as to the procedure.

Changing the laser unit or the rollers will involve putting the printer in maintenance mode. An outline of the Maintenance Reset procedures are given below.

Buy Spares for this PrinterFault Finding:

Horizontal marks on the page are most likely to be:

- corona wire (clean the primary corona wire in the drum assembly using the blue slider)

- scoring of the drum - visible on the shiny surface of the drum itself

- contamination and wear of the developer roller causing greyish marks or grey print

- stray toner, hair or other marks on the optics - clean the window with a dry lint-free cloth.

Greyed print can also be caused by using an incorrectly refurbished cartridge. The printer has an unusual mechanism that recycles used toner but adjusts for the effect of this by changing the bias voltages.

Vertical or recurring marks down the page are likely to be a mark on a roller. Which roller can be determined by looking at the spacing of the marks.

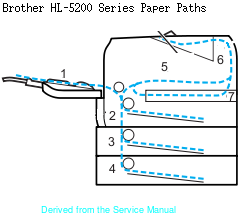

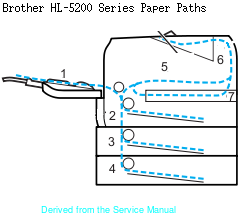

| A Defect Ruler List for this printer is: Paper feed Roller 44.0mm Transfer roller 48.2mm Developer roller 42.7mm OPC Exposure Drum 94.2mm Upper fuser roller 78.5mm Lower Pressure roller 78.5mm | Messages: JAM MP TRAY, point 1 in diagram JAM TRAY 1, built in tray, point 2 in diagram JAM TRAY 2, extra tray , point 3 in diagram JAM TRAY 3, extra tray, point 4 in diagram JAM INSIDE, somewhere around 5 in diagram JAM REAR , Jam near the paper exit 6 in diagram JAM DUPLEX, Jam in the duplex unit, 7 in the diagram |

Process Outline:

The HL-5200 series printers are built to a well established format with a paper cassette in the base, delivery tray on the top and the mechanism in between. An "S" shaped path leads from the tray(s), through the print mechanism and out into the delivery tray.

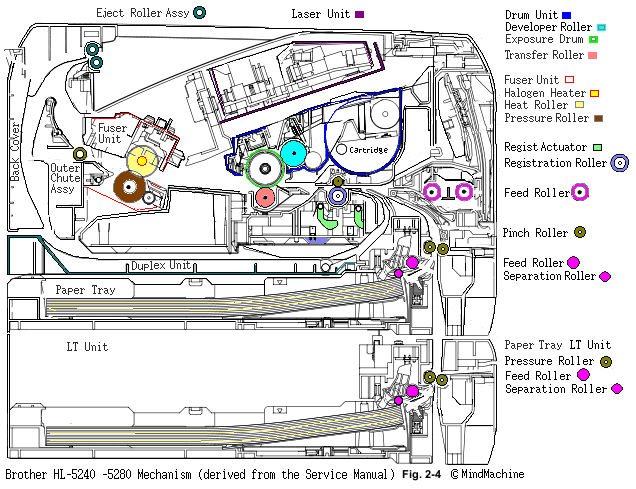

Paper is picked from the tray by a separation roller which begins to push the media from the tray. The paper is driven to a registration station where it is signalled by an actuator and then stops momentarily.

A latent image is meanwhile built on the exposure drum which is metal but coated with two plastic layers together called "OPC" (Organic Photoconductor). The drum is in the center of the printer (its green and rotates clockwise in the diagram). The upper layer of the drum is charged to several hundred volts by a corotron charge unit above it.

The laser assembly above the drum contains a mirror which scans the beam across the drum as it turns. The laser is modulated (turned on and off) rapidly. Where the laser is on the drum's OPC conducts, discharging the surface. Elsewhere the surface is left conducting.

The drum now turns to face the developer roller (cyan blue in the picture). The developer also carries a charge, different from that on the drum and tribo electrically attractive to the toner powder in the cartridge. The developer therefore carries a thin but consistent layer of toner next to the drum. Where the voltage is different the toner adheres to the drum giving a developed image. The paper is now released from the registration station and proceeds between the drum and the transfer roller. The transfer roller carries yet another voltage which strips most of the toner off the OPC surface and onto the paper.

Paper with lose toner on its surface now travels into the fuser - a pair of heated rollers. The heated roller part-melts the toner to the point where it is sticky and the pressure roller forces it into the page. Normally the page exits onto the top of the printer.

Duplex pages partly exit but then reverse back into the printer and travel down the outside of the outer chute and through the duplex unit to re-emerge face down at the registration station.

Whats-In-The-Box:

These printers are a design introduced in 2005 and were succeeded in April 2009. Printers may still be in distribution and offered new in March 2010. Brokers and refurbishes are likely to offer the printer as-is or complete with a recycled toner. The user manual can be found on the Internet. Linux systems come with drivers built in for HL-5240, HL-5250DN and HL-5270DN using BR-Script3.

Warranty:

Originally provided with a 3 year warranty.

Service:

We offer repair in North East England

We are researching service and repair options for these printers.

Maintenance Mode:

Brother printers often have a maintenance mode intended for service technicians with access to a service manual and technical support. The instructions below are intended as a memory aid for technicians, not as a comprehensive how to to for end users repairing their own printers. Note that changing maintenance mode settings without understanding the implications can damage or disable a printer. If in doubt, consult the service manual.

Procedures can differ by printer model because the HL-5240 and 5250 have no LCD panel and fewer buttons than other models.

The HL-5240 and HL-5250 require a Brother supplied Windows program called MAINTE.EXE which should be extracted into the hl5200 folder.

Put the printer into maintenance mode by: opening the front cover, turn on with the GO button held, All the lights come on, then status goes out. Release the Go button and all the lights go out. Press Go for two seconds or so and the Paper LED should light. Close the front cover. the printer should now be in periodic maintenance mode. Now run brmainte.exe. A windows applet allows you to reset the relevant counts.

Items that can be reset are: Fuser Unit, Laser Unit, PF Kit for Tray 1, PF Kit for Tray 2, PF Kit for Tray 3, Paper Feeding Kit for MP Tray.

For the HL-5270DN and HL-5280 a similar procedure can be used.

Put the printer into maintenance mode by: opening the front cover, turn on with the GO button held, the messages "USERS MODE" is shown on the LCD. Release the Go button. Press Go for two seconds or so and the Data LED should light and the message "PIT3 MODE should be shown on the LCD. Close the front cover. The printer should now be in periodic maintenance mode.

The HL-5270DN and HL5280DW also have a Reset Parts Life Menu entered by pressing Go and "+" at the same time until "RESET PARTS LIFE" appears on the LCD. Select the item using +/-, to go back to a higher level press back. Press the "Set" switch to activate an option. Pressing "Back" repeatedly or "Go" will exit the service menu.

Options and Accessories:

There are three optional extras, up to two extra trays, expansion memory and a print server.

Trays

LT-5300 Lower tray expands the paper input capacity. (May still be available)

Two optional lower trays (Tray 2 or Tray 3) can be installed. Each lower tray can hold up to 250 sheets of 80 gsm (21 lb) paper.

With both optional trays installed, the printer can hold up to 800 sheets of paper.

A user guide comes with the LT-5300.

Memory

There is one slot for a Dual Inline Memory Module (DIMM)

The HL-5240 has 16MB base memory and can be expanded to 528MB with a DIMM.

The HL-5250DN has 32MB base memory and can be expanded to 544MB with a DIMM.

Brother's user manual says:

In general, the DIMM must have the following specifications:

Type: 144 pin and 64 bit output

CAS latency: 2

Clock frequency: 100 MHz or more

Capacity: 64, 128, 256 or 512 MB

Height: 31.75 mm (1.25 in.)

Dram Type: SDRAM 2 Bank

SDRAM can be used.

Print Server

TheHL-5240 can use a Brother NC-2100p to connect to a network.

Specifications are

Network interface 10/100BASE-TX Ethernet

Printer interface Parallel

Support protocol TCP/IP, NetBEUI

Management features:

Embedded web server support

SNMP / MIB support

TELNET remote console

BRAdmin Professional compatible

Flash memory for easy updating of firmware

Many other print servers will also work.

Cables

F2A046-10 - IEEE-1284 Bi-directional Cable (Almost any recent parallel cable can be used but older cable may have wiring that will not allow reliable parallel transfer).

LG3077001 - Telephone Line Cord (USA)

Documentation:

Users Guide: LP2049001 (English for USA and Canada)

Quick Setup Guide: LP2053001 (English for USA and Canada)

As usual it is easier to find the US version of the manuals on the Internet - but note that all the part numbers are different.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015, 2016. Some pictures derived from Brother User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.