HP Original Cartridges

Fusers

Refurbished fusers suit experienced technicians with a fleet of printers to maintain.

Reliable Remanufactured Cartridges

One of the merits of the P4014 against a new printer is the low cost of good re-manufactured cartridges.

At the moment we don't sell in the US, but we hope to soon

HP CB506-67902 Fuser for P4014, P4015 and P4515 Printers.

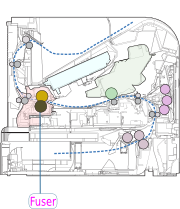

The HP LaserJet P4014, P4015 and P4515 printers are A4 mono laser printers aimed at workgroup use - HP claim a duty-cycle of up to 175,000 pages per month for the P4014 and 225,000 for the P4015. Duty cycle claims are often rather high; a more realistic use might be 2,000 pages per month and up. The basic CC364A cartridges have 10,000 page capacity and a two year shelf life, whilst the CC364X is rated for 25,000 pages. These printers might not suit someone printing less than 500 pages per month because they wouldn't be able to use a cartridge before it's life expiry date.

The design is robust. These printers are based on the LaserJet 4250/4350 which have been office workhorses since 2002. The main differences are styling and the speeding up normal for a new generation of printer. The P4014 series have a faster formatting processor and more powerful drive-chain. In fact the paper, drum and fuser motors are all separate items. The fuser is a re-design quite similar to that in the LaserJet 4200. A similar design continued in the LaserJet Enterprise 600 M601, M602 and M603 series and then the M604, M605, M606 series (similar, but not compatible).

About the Fuser

Fusers use a combination of heat and pressure to adhere toner powder to a page giving laser printer material its characteristic clean look and durability. A ceramic heater momentarily raises the temperature of paper to around 150°C. Paper and toner are also pressed together by passing through a nip point between the heater and a pressure roller driven by a motor.

There are two versions of the fuser kit:

- CB506-67901 110 VAC Fuser for the US and Japan

- CB506-67902 220 VAC for Europe, UK and most of the rest of the world.

The difference is the resistors of the ceramic heater. A fuser draws quite a lot of power when it operates so they are designed for the electricity supply of the region they will be used in.

Fusers are usually only available in the correct voltage for the region. In practice construction sites and some ships use 110 Volts in Europe, whilst some data centres prefer 220Volt in the US. HP can ship fusers and maintenance kits anywhere on about 3 days notice but the distributors are often unwilling to do it.

Maintenance Kits

Fusers are available as separate parts however most fusers for mono printers are bought as maintenance kits. A mono printer maintenance kit contains a fuser, transfer roller and some paper feed rollers. The Service Manual gives the codes as CB388A and CB389A. In 2013 HP Partsurfer said:

- CB388A(CB388-67901)Maintenance kit - For 110 VAC - Includes fusing assembly, transfer roller, transfer-roller tool, tray pick-up rollers, eight feed rollers,and gloves

- CB389A(CB389-67901)HP LaserJet 220V PM KIT

… which is very similar to the Service Manual. (Those codes are widely used but things are now a little more complicated see ( below ).

The fuser should last well over 200,000 pages. The printer will automatically warn that a kit is needed then and at 225,000 pages the kit any guarantee of service life expires. The fuser may go on working; its actual wear rate is determined by the material passing through it - the paper and toner. (The maintenance interval can be changed in the service menu, and the warning message temporarily suspended).

Maintenance kit parts are considered user installable by HP, even the fuser. Some IT managers might consider them technician fittable (fewer accidents). Technicians will get used to the job and be able to do it quickly. Fitting the parts isn't difficult, as we show here, but ordinary users might be thrown by a job that only happens once in 225,000 pages. The fuser is held in by two clips. The rollers all have clips holding them on their axles. There are more instructions here and covering all the series (P4014, M601, M604) here.

Rollers will last 50,000 to 200,000 pages or more - depending on the nature of the paper and which trays are used most. Whilst rollers and fusers don't necessarily wear out at the same rate when a printer needs a fuser the chances are it also needs a set of rollers - although they may have been replaced once or twices as kit CB506-67904

Maintenance kits also include a transfer roller. Transfer rollers are black conductive slightly spongy rubber and are located underneath the print cartridge and specifically right under the drum. The transfer roller pulls the electrostatic image away from the drum and onto the paper. There is a counterpart PCR roller built into every print cartridge and some printer designs make the transfer roller part of the cartridge as well - but HP / Canon don't do that. The transfer roller is very lightly clipped into the base of the printer and it's cog driven by teeth at one side of the drum. The transfer roller is also available as seperate kit CB506-67903

With a set of parts, a clean and a cartridge the printer is effectively a new machine.

Maintenance Kit Types

Maintenance kits themselves come in several varieties.

There is straight-forward HP product that comes with an instruction sheet and their warranty. HP have a good record of honouring warranty.

There are "brown box" versions of the same thing. HP sometimes charge a bit of a premium for making up the maintenance kits, or the kits run out, so some distributors do the same thing in a plain box at a lower price.

There are also refurbished fuser versions of the same thing. The main things that go wrong in a fuser are the sleeve, lubricant and heater. They can all be replaced. Paper feed rollers can't be refurbished so they should be new originals. Some refurbished fusers might be accompanied by "compatible" rollers - (we generally don't think compatible rollers are as good so we avoid them where possible). We have reservations about refurbished kits and fusers, so we only recommend them for experienced technicians.

This page aims to be comprehensive on the P4014 / P4015 series fuser but that makes it lengthy. If you just want to buy a fuser prices are shown live in the side-bar. If no price is shown the product exists, but isn't available at present. Catalogue items are followed by links within this page and others that might prove helpful.

If you are trying to solve a problem some of the details below might help.

CB506-67901 and CB506-67902 Fuser

What you actually get is a fuser marked RM1-4554

(110V) or RM1-4579

(200V) in a box probably marked CB506-67901 or CB506-67902

Those "RM" numbers appear on the piece of kit, but not in the service manual; it uses codes CB506-67901 and CB506-67902.

RM1-4554 and RM1-4579 are the actual part numbers, (unusually the numbers for the 110V and 220V part are not sequential). The numbers CB506-67901 and CB506-67902 may have been intended for "kits" - a fuser in a white box with instructions. CB388A and CB389A look intended as "user version" maintenance kits, whilst CB388-67901 and CB389-67901 would be the engineering brown box or possibly engineering exchange codes. Most web sites just equate CB506-67902 with RM1-4579-000CN and its list of successors. - What HP intended is lost in the mists of time (- well, 2008).

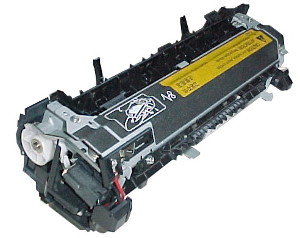

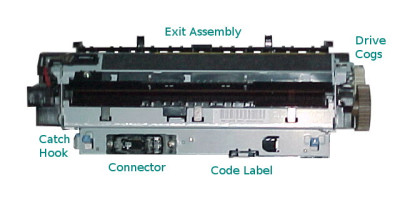

The fuser is like that of predecessors in being user changeable, its a matter of taking the rear output bin / door off (remove any duplexer first - lift it slightly then pull it out). The rear door is on two bosses, push it slightly one way and then the other so one, then the other disengage from the printer body.

Note that the fuser will be hot when the printer has just been in use. HP recommend allowing the fuser to cool for 5 minutes before handling it. (Sometimes they say 30 minutes and it does take a while to cool, but few technicians can afford to take 30 minutes out). Fuser parts are delicate, the plastics are meant to work at high temperatures and are brittle. A fuser will be damaged if it is dropped.

The fuser has two blue release tabs, squeeze the tabs and the fuser assembly draws straight back out of the printer. The connector grips a bit and wiggling it fractionally helps.

When replacing the fuser make sure both sides clip into place. It is possible for the fuser to work when not pushed fully home but gear damage will result. (See RC2-2432).

Fuser Problems

People generally know they need a maintenance kit because:

- The printer asks for a maintenance kit after 200,000 + pages, somewhat before the fuser is likely to fail. It gives the message "PERFORM PRINTER MAINTENANCE".

- If something in the fuser does actually fail the printer displays an error such as

Error 50.1

more on this in a moment.

Other than the prompt, there isn't one single specific error message that you need a fuser. Expectation historically was that someone "technical" looked after the laser printers. The computer or copier company would perform maintenance tasks (clean corona wires, change rollers, periodically replace the fuser and drum. In 1984 Canon and HP developed a cheap little laser-printer with an all-in-one cartridge that needed less specialist attention - the "LaserJet" brand became a top seller. Big printers like the LaserJet 8100 and 9000 often had plug-in fusers and HP's development of the LJ-4000 brought that easy repair to smaller office printers.

LaserJet P4014 printers are a transition point; early versions of the firmware had a technician-oriented reset, later versions have a user-oriented reset. Today's successor is the M604 series and all the major parts are regarded as user changeable - and have "consumable" error code 10. Internally the M604 is a refinement of the P4014 engine but firmware developments should give more help to non expert users.

P4014 users can easily change the fuser; but the firmware was not yet designed so that they would know to change the fuser. It might need a technician to suggest that. Progress is sometimes gradual.

A regrettable source of fuser problems is that people put inappropriate media through the printer that melt in the fuser. Select "transparency" in the driver menu before loading the tray and printing to transparent material. Some printers attempt to spot user mistakes but it's never foolproof.

More on fuser modes here.

Fuser Modes

Some errors that imply a new fuser at first glance won't actually be solved that way; so it's worth briefly looking at those.

Fuser temperature is adjustable in the print driver and in the Print Quality

submenu under fuser modes

. The printer driver will normally select an appropriate mode but it is overrideable to one of four settings: NORMAL, LIGHT1, LIGHT2 and HEAVY. The HP Service Manual (p30) says:

- NORMAL: Used for most types of paper

- LIGHT1: Used for most types of paper.

- LIGHT2: Use this mode if you are experiencing wrinkled media.

- HEAVY: Used for rough paper.

It then somewhat oddly says:

The default fuser mode is LIGHT1 for all print media types except transparencies (LIGHT2) and rough paper (HEAVY).

... rather implying that normal isn't used much.

Remember that what the documentation says was written as the printer was conceived and may be overridden by later decisions on firmware and drivers. There certainly have been several major firmware revisions for the P4014 series printers. It is one of those machines where firmware revisions really matter.

It is better to use the print driver to set the media type as that overrides anything set at the control panel.

It is worth reiterating that transparencies should be selected in the driver and not overridden in fuser modes

. The printer will be damaged if a transparency melts. As it happens these printers use a low-melt toner so they may be less prone to this problem - but better safe than sorry.

Fuser Problem in Early Printers

Printers with firmware earlier than version 04.060.7 had an odd fault where the printer would display processing job

on the control panel, spin up then down again several times and then go back to ready (idle) without doing anything. The problem was a faulty fuser but a fault in the firmware meant the error message did not display. Upgrading the firmware gets the correct messages.

Fuser Error Messages

The printer is able to detect and report some fuser faults as "Error 50", particularly those related to problems heating up.

Internally a fuser is fairly simple - a heated element and a pressure roller. The heater softens the toner powder and the pressure roller forces it into the page.

Sleeves and pressure rollers are more difficult to monitor, all most printers do is to see if the paper emerges. More on this shortly.

Heaters have electrical characteristics that can be monitored by printer circuits; current draw, heating up in the expected manner. The error messages below are derived from these:

- 50.1 : Low fuser temperature. Try cycling the power but if the error persists the fuser heater has failed. If there is doubt the problem can be verified using a multimeter to measure resistance across the power pins. The normal solution is to replace the fuser.

- 50.2 : Fuser warm-up service. The fuser did not warm sufficiently in the time allowed. Try plugging the printer directly into a wall socket, not using extension or other cables as these can cause a voltage fall. (see here). This fault may implicate theenvironment sensor thermistor or DC controller. The simple answer is turn the printer off, leave it for half an hour letting the fuser cool, turn it on again and hopefully the probelm should have gone away.

- 50.3 : High fuser temperature. If the fuser temperature goes too high it gives this error. A likely cause is that the mains power supply to the printer drifted too high. Check that the fuser really is the right model for the printer. This fault might also be caused by a bad environment sensor thermistor or DC controller. Check for things like an envelope or label wrapped round the fuser foil. Once again, the simple answer is turn the printer off, leave it for half an hour for the fuser to cool, then try again.

- 50.4 : Faulty fuser. In the past this has implied that the temperature did rise, but insufficient because of bad AC line voltage. Similar to 50.2 there is an implication of a DC controller issue.

- 50.5 : Inconsistent Fuser. The printer thinks the wrong model fuser is fitted. Verify the Voltage and Model.

- 50.6 : Open Fuser. Fuser heater cutoff operated.

- 50.7 : Pressure release mechanism failure.

- 50.8 : Low fuser temperature. Secondary thermistor. A wrong temperature here might imply fuser-sleeve failure.

- 50.9 : High fuser temperature. Secondary thermistor - possibly fuser-sleeve failure.

HP use the same error codes across most of their printers, there is more on themhere.

Fusers can also go wrong in ways the printer can't fully detect. The fuser sleeve is the most likely issue. There is no specific mechanism to monitor the integrity of the fuser sleeve.

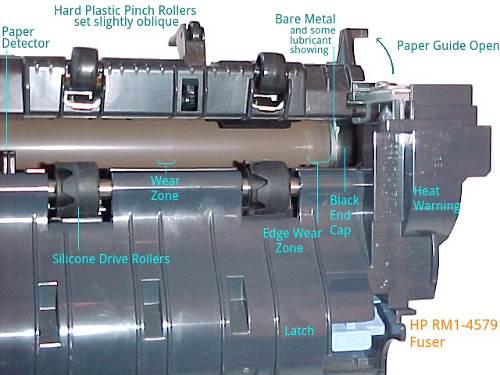

Looking into a fuser showing the brown sleeve and some signs of wear typical in a used unit. Damage in a failed unit is more dramatic, the brown sleeve is torn and bits may emerge with printed pages.

It is possible to turn the roller using the big brown cog on the side. It will be stiff - that's the pressure from the black pressure roller working against the nip point.

Visible Fuser Faults

The non-stick sleeve in a fuser can become damaged and this will tend to cause regular marks on the page, near the edges of a page at first. This wear pattern is sometimes called edgewear

. The problem seems to arise because of the uneven distribution of stress contours across the fuser - they are greater at the edges because of the 0.1mm displacement caused by office paper. Thick papers may give edgewear patterns earlier in the fuser life.

Fuser rollers and the sleeve in the LJ 4014 series can get contaminated or damaged. A typical contamination problem might be envelopes or sticky labels where some glue residue sticks due to heat in the fuser. The fuser will then make an irregularly shaped splodge on the page at intervals of 94mm (which is the diameter of the fuser rollers). It is possible to clean marks off a fuser sleeve- try soapy water applied with a cotton bud first and if that doesn't work try isopropyl alcohol ( IPA) as a solvent.

Later the sleeve will degenerate entirely and bits of it may emerge from the printer. Pages may still come out, but the toner-powder doesn't stick to them properly.If the sleeve degenerates to the point where paper can't move then the paper exit phto-interrupters won't work at the right time and the printer will give a paper feed error.

This problem is usually quite easily spotted if you take the fuser out - the sleeve is visible inside the fuser and the marks and rips in it are self evident.

Fuser Repair

If you are quite clear that you have a damaged fuser then the normal answer is to buy a replacement fuser or perhaps a maintenance kit if the printer has been in use for some time. The kits are CB388A (110 Volt for US and Japan), CB389A (220 volt for UK, EU)and the European versions are available on this page.

If the printer won't print a configuration or supplies status page because the fuser is dead have a look at its internal web server (you may need the IP address) and that should give statistics on maintenance life.

Whether you would prefer a new fuser, a refurb, compatible or even just the parts to fix the fuser is something we look at below.

If the fuser is replaced then it might be an idea to reset the maintenance count. There is more information here.

Fuser Principles

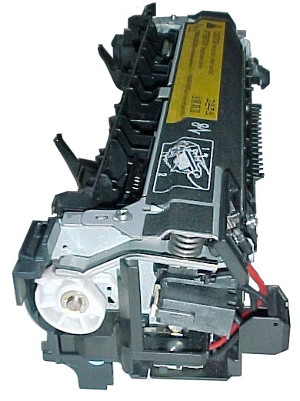

Fusers can be repaired; a refurbished fuser is one that has been repaired. Repairing a fuser is not quick and simple; doing the job needs information about how it works and a source of reliable parts.

Rebuilding fusers need not be as difficult as it is with the LaserJet P4014 series. Some manufacturers list and supply the parts themselves. That isn't true for HP and Canon's instant-on fusers (at least at the time of writing).

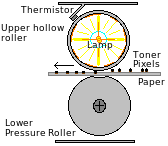

Traditional fusers use a heated roller. This is an aluminium roller with a heater like a halogen lamp mounted in the middle. When the printer starts it heats the roller but to do this it has to turn the lamp on then run the motor for a minute or so. When the printer might be used the fuser is kept hot by turning the lamp on for ten seconds or so every minute and turning the motor a bit. The fuser is allowed to cool when the printer goes into power-save mode but it will then need a minute or so to warm up when the user sends a print job.

Instant-On Fuser

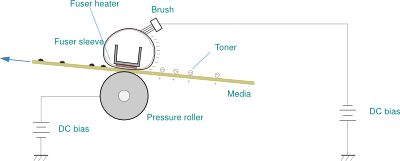

HP/Canon devised the "instant on" fuser used in almost all their recent printers in the late 1990s. The heated roller is replaced by a ceramic heater that only powers up when it is needed. The heater is pressed firmly against the page by springs working against the pressure plates so that it can transfer enough heat.

The print would smudge, except that the fuser is wrapped in a Teflon sleeve that rotates with the pressure roller and the page. The sleeve is made of polytetrafluoroethylene material, in these printers it is on metal backing. Because very little heat is stored in the sleeve the fuser can simply be turned on whenever it is needed - unlike older fuser designs. It is rather surprising how well the instant-on sleeves work, they last about as long as the old Teflon coated rollers did.

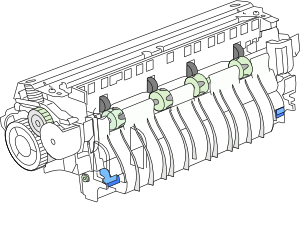

Specifics of the CB506-67902

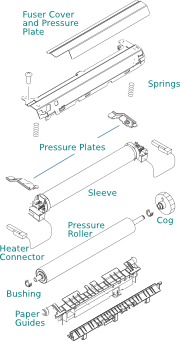

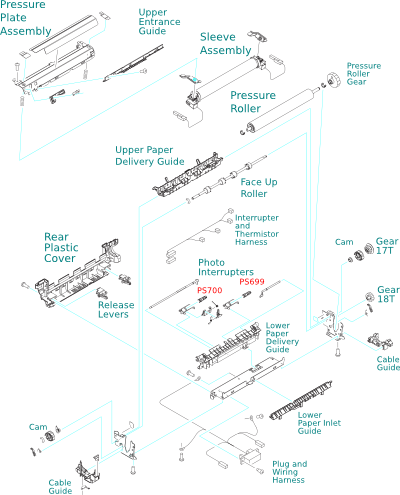

The construction of the fuser is illustrated below - (the picture is derived from p380 of the HP service manual).

The core of the fuser is at the top right of the picture. The pressure roller sits in the side-plates on a pair of bushings. The heated sleeve assembly sits above it on slides which are free to move several millimetres up and down. The pressure plate assembly is mounted above that, bearing down on the sleeve through springs and two pressure plates.

The pressure roller gear is a large cog on the fuser side. The sleeve turns because of frictional contact with the pressure roller and / or the paper passing through. The other gears drive the rollers on the face-up shaft.

The fuser in these printers is driven by it's own motor ( RM1-5051). The motor isn't part of the fuser but drives it through the fuser drive side plate ( RC2-2432). A failure of the fuser might be due to the sleeve sticking and being too difficult to turn (see below). Equally the issue might be the motor itself, not starting or lacking power. There could also be a fault in the cog chain - for instance caused by not pushing the fuser so it clicks home properly. The printer software may not issue the command to run the motor because the machine is already going to paper jam. An issue can probably be resolved by putting the printer in diagnostic mode

.

A critical part of a sleeve-based fuser does not show in most diagrams. Between the heater element and the film is a layer of lubricant. This is applied when the fuser is made as a single thin stripe on the heater. There must not be too little lubricant or the fuser sleeve will not turn properly and some pages are likely to show smeared print or the printer will misfeed stopping with a page in the fuser. There should not be too much lubricant or it will tend to emerge from the edges of the sleeve and contaminate pages.

A different lubricant is used in these high performance printers with metal backed sleeves to that used in the LaserJet 2200. The wrong lubricant will not perform correctly.

This is the connector J128 on the power supply board that the fuser mates with. Any damage here such as arcing on a contact might give obscure problems.

At the time of writing (August 2013) we don't supply parts to refurbish CB506-67902 fusers. Some Chinese and US sites do make them available. Far too many Chinese suppliers are claiming to make sleeves for HP; if it were true they would claim to be making them for Canon. Traditional fusers work to clearly understood principles but these do not so it is difficult to be sure of materials. There is also some difficulty dismantling and reassembling fusers and people buying the materials are inclined to blame the supplier rather than their own lack of skill; you can't expect a 100 percent success rate or long lived results from every fuser. (see below).

If you want to buy some volume of parts for refurbishing P4014 fusers (20 kits or more) then we may know suppliers that can provide them. (Not quite everything we know is in this essay)

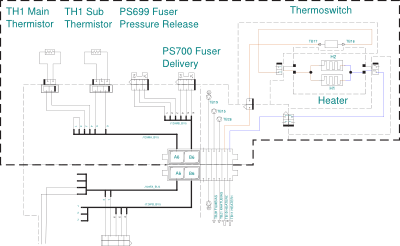

Fuser Monitoring

The fuser carries two thermistors to detect it's temperature, one in the middle (TH1) and another at one side (TH2 gives the 50.8 and 50.9 errors). The temperature is driven high quickly as a print-job starts; if the expected temperature change doesn't happen a failure to warm up or a high temperature will result in an error message and the printer stopping.

If the control circuits go berserk and the fuser starts to overheat a thermal cutout isolates it. The message then is 50.6.

The fuser has a photo-interrupter to detect paper delivery (PS700)

The fuser is not a complicated mechanism; it has a repertoire of faults: the reportable "error 50" issues, observable print defects and a few possible misfeed issues.

Fuser Faults

Fuser faults that result in it not warming up properly or overheating will be detected by the thermistors and result in a 50.x error. If the problem was a temporary power-brown out or a bad contact then turning the printer off, waiting, then turning it back on might clear the fault.

Fuser non-stick sleeve degeneration will first result in a regular pattern corresponding to the marks on the fuser sleeve or pressure roller. The printer has no sensor that can detect this - however:

- Marks on the paper will be at a characteristic 94mm spacing down the page.

- It is possible to take the printer out and spot the problem. The foil is visible through the slot where paper enters and can be turned by the large cog.

Ultimately failure of the sleeve will result in paper misfeeds, and when it degenerates completely the problem will probably be evident in material gathering in the rear output bin /door.

Fuser and Mis-feeds

Misfeeds are also moderately likely in the fuser in the "normal" course of events - as they are throughout the paper path.

Fast printers give some problems identifying the cause of misfeeds. The paper takes about a second to move from the tray to the top of the printer and by the time one page is going through the fuser the next is under the cartridge drum and the pickup roller is turning for the next. Problems that look like paper jammed in the fuser might actually be a failure to pick up the next page that caused the printer to halt.

Some guide to what the printer thinks caused the problem is the Error 13

message on the printer display. Believe what the message says, not where the paper is found in the path. The message records what stopped the printer. Error 50 is looked at above. Error 13 here .

The printer keeps an error log and that records the history of a problem.

If the fuser sleeve is intact then the fuser is not very likely to cause a misfeed. However there are possibilities:

- The fuser sleeve is lubricated with high temperature grease to allow it to move fairly freely. If the grease is wrong in some way then the sleeve will not move well - or at all. This may be detectable with the fuser out of the printer. It is never particularly easy to turn the pressure roller cog (and harder still when the fuser is cold) but an exceptionally stiff roller or one that isn't turning the foil would be suspect. There are some ideas on why this might happen below.

- The fuser has two opto sensors. PS700 is the exit sensor. If it fails to operate at the correct time the printer will stop. The sensor is worked by a flag and a lever and sometimes a previous paper jam dislodges the flag. A few fusers are notorious for giving problems due to bad opto-sensors. The CB506-6790s does not have a reputation for this problem.

- The rollers in the fuser are hot and not unknown to get labels or even whole envelopes stuck to them. I have seen fusers with envelopes so neatly wrapped around the roller that it looks as though it were designed that way. The fuser may give temperature errors - but it may succeed in working well enough to give a misfeed.

The fuser sleeve is delicate, the slightest tear will spread and destroy it. Also when the fuser has been used in the last few minutes its parts will be hot. Be wary of touching it.

With the fuser out of the machine and cold the pressure roller cog should move evenly, though not necessarily easily. The sleeve material should rotate as well. There should be no sudden sticking points.

A possible cause of sticking points is that the fuser lubricant has dried in an odd pattern. It isn't clear how (or if) the lubricant is distributed in an HP factory - we don't think fusers are actually given a live test.

With refurbished fusers practices no doubt vary. Unfortunately the way the industry operates makes refurbishing processes rather opaque.

A suggestion is that all new fusers and especially refurbished units should be run for at least 200 pages on installation. This will make sure the lubricant is thoroughly distributed. Historically an engineer wouldn't leave a printer where some major work had been carried out without giving it that sort of test, but practices have changed as cost and time constraints have tightened.

Other possibilities are:

- Paper may deflect before it reaches the fuser and hit the paper guides round about. This is likely to be due to a dirty contact somewhere in the print cartridge well or the static discharge path. Very flimsy paper also does this, it bends to easily in an electrical field. The misfed page is likely to be crumpled like a concertina at it's leading edge.

- Both fuser sleeve and pressure roller have electrical contacts. If the voltages are wrong there could be misfeeds as well as image quality problems and a buildup of dirt on the fuser rollers. It is difficult to check any of the high voltages in the normal course of events of course, and those on the fuser aren't very accessible.

- Timing of pages might be bad due to problems with pickup and feed or more likely with the registration / pre-transfer roller. Misfeeds like this are likely to be sporadic and the position of the text on pages that do emerge is likely to be a bit erratic - some pages will miss print off the top of the page, others off the bottom. Intermittently one will jam in the fuser. The true fault is likely to be the registration station sensors just before the cartridge.

What HP Says

HP maintains a database of spares called "partsurfer", which is often informative (but intermitttently wrong). Experiments in June 2015 looking for fuser / maintenance kit related codes gave results like this:

| CB388A | No information - partsurfer often doesn't respond to "user oriented" spares numbers. | CB388 | CB388-67901 Maintenance kit - For 110 VAC - Includes fusing assembly, transfer roller, transfer-roller tool, tray pick-up rollers, eight feed rollers,and gloves CB388-67901-BU (same again) CB388-67901-PCA Replacement 110v Maintenance K CB388-67902 Replacement 110v Maintenance K CB388-67903 Replacement 110v Maintenance K CB388-90902 MAINTENANCE KIT INSTRUCTIONS CB388-90904 Install Guide CB388A HP LaserJet 110V Maintenance Kit | RM1-4554 | RM1-4554-000CN FIXING ASSY, 110-127V RM1-4554-020CN FIXING ASSY./ 110V RM1-4554-030CN FIXING ASS'Y RM1-4554-090CN FIXING ASSY |

| CB388-67901 / CB388-67902 / CB388-67903 | Replacement 110V Maintenance Kit Part CB388-67901 is no longer supplied. Please order the replacement, CB388-67903 then Lists HP LASERJET P4014DN PRINTER HP LASERJET P4014N PRINTER HP LASERJET P4015DN PRINTER HP LASERJET P4015N PRINTER HP LASERJET P4015TN PRINTER HP LASERJET P4015X PRINTER HP LASERJET P4515N PRINTER HP LASERJET P4515TN PRINTER HP LASERJET P4515X PRINTER HP LASERJET P4515XM PRINTER HP LaserJet P4014 Printer | CB506-67901 | Fusing Assembly - For 110 VAC - Bonds toner to paper with heat HP LASERJET P4014DN PRINTER HP LASERJET P4014N PRINTER HP LASERJET P4015DN PRINTER HP LASERJET P4015N PRINTER HP LASERJET P4015TN PRINTER HP LASERJET P4015X PRINTER HP LASERJET P4515N PRINTER HP LASERJET P4515TN PRINTER HP LASERJET P4515X PRINTER HP LASERJET P4515XM PRINTER HP LaserJet P4014 Printer | RM1-4554-000CN | Fixing assy 110-127V and gives an "is used in list as follows: HP LASERJET P4014DN PRINTER HP LASERJET P4014N PRINTER HP LASERJET P4015DN PRINTER HP LASERJET P4015N PRINTER HP LASERJET P4015X PRINTER HP LASERJET P4515N PRINTER HP LASERJET P4515TN PRINTER HP LASERJET P4515X PRINTER HP LASERJET P4515XM PRINTER HP LaserJet P4014 Printer but gave no functional equivalents Curiously, there isn't the "no longer supplied" message with "Please order the replacement, CB506-6790". |

| CB389A | No response - partsurfer often doesn't respond to "user oriented" spares numbers. | CB389 | CB389-67901 Maintenance kit - For 220 VAC - Includes fusing assembly, transfer roller, transfer-roller tool, tray pick-up rollers, eight feed rollers,and gloves CB389-67901BULK Replacement 220v Maintenance K CB389-67901BULKRU Replacement 220v Maintenance K CB389-67902 Replacement 220v Maintenance K CB389-67903 Replacement 220v Maintenance K CB389-67903-BU REPLACEMENT 220V MAINT KIT CB389-67BULK REPLACEMENT 220V MAINTENANCE K CB389A HP LaserJet P4014/4515 PM Fuser 220 VAC Kit CB389AR HP LaserJet 220V PM Kit HWP-CB389A LaserJet 220V PM Kit | RM1-4579 | HWP-RM1-4579-000CN Fixing assy 220V HWP-RM1-4579-020CN FIXING ASSY./ 220V RM1-4579-000CN FIXING ASSY, 220V RM1-4579-020CN Fusing Assembly - For 220 VAC - Bonds toner to paper with heat RM1-4579-030CN FIXING ASS'Y RM1-4579-080CN FIXING ASSY RM1-4579-210000 Fixing assy 220V RM1-4579-210CN FIXING ASSY RM1-4579-BULK FIXING ASSY./ 220V |

| CB389-67901 / CB389-67902 / CB389-67903 | Replacement 220V Maintenance Kit Part CB389-67901 is no longer supplied. Please order the replacement, CB389-67903 And then gives a list including HP LASERJET ENT 600 M602X PRINTER - which is wrong. | CB506-67902 | Fusing Assembly - For 220 VAC - Bonds toner to paper with heat | RM1-4579-000CN | Fusing Assembly - For 220 VAC - Bonds toner to paper with heat. Part RM1-4579-000CN is no longer supplied. Please order the replacement, CB506-67902 |

Partsufer can be idiosynchratic; accepting "CB389" as a wildcard and listing variants of the code, but rejecting the full user-code CB389A. Despite partsurfer's assertions, The CB389-67901 doesn't fit the LJ-M602X - or the LJ-4. The wild mix of upper and lower case suggests partsurfer is cobbled together from all sorts of historic HP internal data.

Web Research

A Google query for CB506-67902

in August 2013 suggested About 15,100 results (0.24 seconds)

which could suggest an estimate of how many people are offering these spares worldwide. The code doesn't appear to apply to anything else much and Google images was fairly consistent in showing fuser-related parts. The query gave the following results in top 30+ positions:

misco.co.uk £189.16, dabs.com £234.56= £195, amazon.co.uk(ILGS) £219.54, tonergiant.co.uk £178.91,lambda-tek.com £167.76, tonercare.co.uk £166.98, ebay.com selling fuser parts, amazon.com (Order Parts Today) $250.06, hpfuserkits.com (Slon) no price, printscancopyfax.com (refurb) $219.00, partsmart-corp.com heating element only $28.60, ebay.co.uk (n_e_fing2011 )£220.14, aliexpress.com (Yuanfeng Technology Industry (HK)Co) $196.00, getprice.com.au $416.63 AUS, getprice.com.au again, getprice.com.au again, equanet.kelway.com irrelevant page, jp-uk.co.uk £176.90, laserink.co.uk refurb £90.00 new £210.00, inkntoneruk.co.uk £228.89 (free delivery), impactcomputers.com $319.00,shima-uma.com £207.40, comp-unlimited.co.uk £185.00, buy-hk.com no price, artonery.com €333.20, fptg.co.uk £180.25, (mindmachine.co.uk - this page), atemy.net heating element only, idealo.co.uk (n_e_fing2011) £189.22 and others), tonergreen.com $291.99, centralpoint.nl €250, idealo.de 249.83 €, mysuresupply.ie€266.90, made-in-china.com no price, psaparts.co.uk £223.85

Prices noted are for a new item without tax. The list is as encountered. We haven't bothered with currency conversion - half of our readers are outside the UK and are more interested in dollar prices. Our price on this part at the time of research is £174.41 (in stock) and for a refurb £86.21 (5-7 day delivery).

Non of the sites visited gave any obvious information or help beyond what is in HP Partsurfer or the distributors P&A lists. However "CB506-67902" is for a 220 volt fuser so it tends to exclude US sites - which are often far more informative. Perhaps we need to re-run the exercise using "CB506-67901" as well.

Supply Situation

Fusers for these laser printers were quite expensive at nearly £200 in 2013 but this fell back to under £170 in 2015. It is arguable that since the fuser will last 225,000 pages the cost is under £0.01p per page but it's still higher that the cost on a whole new P1102 printer. eplace the fuser rather than buy a new printer is that these P4014 series machines have low running costs of around 1p per page or less, they are reliable and easy to maintain when they go wrong. Lesser printers are more trouble and cost much more to run - often 2.5 per page or more (HP's P1102 delivers toner at 2.6p per page. The alternative to buying a new fuser or maintenance kit for a P4014 is to buy a new Enterprise 600 M601 printer - base price starting from £435.60.

The fuser is still quite expensive for what it is. HP presumably set the price to be competitive with what they see others in the market doing and to make a profit from spares if they can. This kind of device normally has one global manufacturer. In this case HP has one clear competitor - Nupro making maintenance kits as noted in the article on the CB388A here.

We aren't selling the Nupro compatible maintenance kit (as yet). It does offer some price advantage but the Nupro brand has raised support issues in the past.

Refurbished Fusers

Another alternative is a refurbished fuser which we do offer - when they are available. There is a substantial cost saving in buying a refurbished fuser (they tend to be about half the price of a new one). Buying refurbs might also be the environmentally responsible thing to do. We have reservations about refurbished fusers. At one time we did some refurbishing ourselves but it is difficult to get to scale in a local market. The real problem is to source reliable components. Few if any sources actually do refurbishing in the UK (If you know differently let us know). Most of the actual refurbishers seem to be in BRIC countries with low wages and perhaps perhaps more innovative investors. Unfortunately what they do in terms of material and testing is opaque; they don't say. Like HP and Canon, they want to keep their secrets but this reduces our confidence in the product. Reliability is often OK once the fuser passes the ten day mark but failures at first use are too common. We recommend refurbished fusers to experienced technicians and maintainers familiar with the problems and trying to make field-service cost effective. (Scientists and technicians fixing office and home printers are often interested in getting the parts as well). If you need reliability the HP product has clear advantages. It's the old FUD factor. If you don't buy the brandname, fear, uncertainty and doubt creep in. You can't be criticised for buying HP products - except on price. Refurbished parts are more of a worry.

If you search online for "polytetrafluoroethylene coating process" it is a major area of interest. There are lots of uses for coating things in teflon. Basically it needs spray-shop equipment and an oven for finishing.

Sleeves and belts of material can also be made by dipping a mandrel in a succession of baths to provide a layered structure giving strength, lubricant resistance and then non stick properties and then letting the results cure. Coated metallic sleeves may be more difficult, as there is the nature of the metallic sleeve to consider.

Sleeves potentially contain half a dozen layers, each microns thick. Patents dating from the early 1990s onwards give some outline of what the layering might be, but no specifics. It would require detailed literature search and lab analysis to reverse engineer the precise composition of a fuser sleeve.

Something looking like a fuser sleeve can be made quite easily. Something that performs correctly for 250,000 pages would be more difficult and require quite a lot of testing. There is room for doubt about it's practical performance unless suppliers give details of what they have done to emulate or exceed the performance of originals .

Fuser Repair Components

If the suppliers of refurbished fusers were more open about what parts they change and where they source components we would be more interested in their products. We have considered offering the components for fuser repair. The main point of failure is the sleeve which is a polytetrafluoroethylene (PTFE) or silicone material usually coated on a metal foil (ie teflon). Sleeves have no reason to be particularly expensive.

We get quite a few emailed offers of fuser film sleeves from China, and anyone can find potential suppliers on Alibaba. The main problem with such suppliers is credibility; they claim to be working for HP, but HP publishes a list of suppliers and they aren't on it - perhaps they are subcontractors to Canon? Our impression is that actual HP suppliers generally keep quiet. With doubt about, by the time parts have been sourced and tested the price goes up - the vendors on eBay mentioned above were charging half the price of a refurb fuser - and to replace a fuser foil you need the right grade of PFA grease and that can be difficult to identify and source.

Other parts needed are the ceramic heater rods (again they are available on eBay), the pressure rollers and the bushings. Our feeling is that the costs mount up to not far short of a refurbished fuser and with much more doubt about provenance (that FUD factor again).

New Fusers

Fuser CB506-67901 part is listed by all the UK distributors and several hold stock - sometimes of over 100 units. Maintenance kits are still more popular, one distributor has stock of nearly 700 at the time of first writing (2013). We think demand for fusers is continual. We would expect people with these printers to need a new fuser or maintenance kit every 10-20 cartridges.

Our sources of supply mean we can usually ship these fusers very economically. In 2013 the price was about £174 for the fuser, £221 for the maintenance kit. In June 2015 prices had fallen to around £160 for a fuser and £185 for a maintenance kit.

The remarks on pricing and availability are guidelines based on our knowledge of the market in August 2013 and revised in 2015. Our prices change with distribution lists - see the sales-bar on the right. Prices there are based on a daily comparison of about 10 UK and European distributors, selecting the best offer on the basis of availability and price together with carriage cost. Note that if we don't say its a third party or refurbed unit we are selling HP original fusers and kits. catalog.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalogue. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.