HP Original Cartridges

Roller Kits

Reliable Remanufactured Cartridges

One of the merits of the P4014 against a new printer is the low cost of good re-manufactured cartridges.

At the moment we don't sell in the US, but we hope to soon

Error Message 13 for HP P4014, P4015 and P4515 Series Printers.

13.xx.yy JAM IN TRAY xx

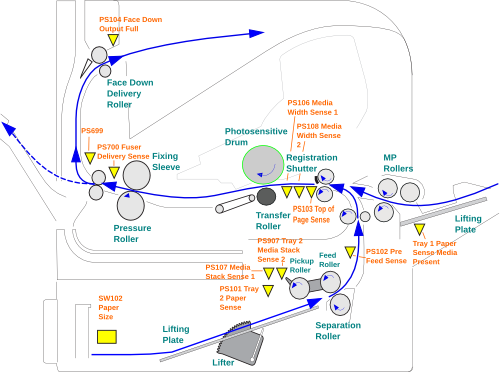

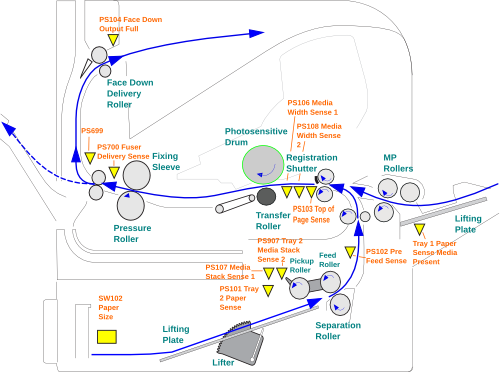

HP uses "Error 13" to alert users that paper is not moving through the printer properly. Printers usually detect this using a series of infra-red optical beams and reflectors along the paper path. If one of the beams is broken or made when it should not be, the printer halts and reports an error (see WG8-5624). If the printer did not halt when an error occurred the paper feed system might continue cramming paper into the machine, potentially damaging something expensive like the drum or fuser.

Paper jams are more or less inevitable in modern printers because they print using cut sheet paper and that is quite difficult to handle. Paper sticks to the stack it was supplied in, separates but feeds skewed, or the electrostatic fields inside the printer attract it unduly and it collides with something or even wraps around the drum. Considering the difficulties, a modern printer is a miracle of reliability. But if you are experiencing a run of paper jams, you probably aren't in a mood to congratulate the designers.

One of three things is usually wrong:

- The paper or other media such as envelopes or labels are wrong for the printer.

- Something is stuck in the paper path as a result of a previous jam.

- The pickup and feed rollers are damaged or worn out and need to be replaced.

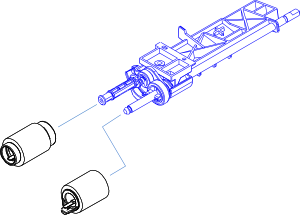

"13" errors are often straightforward - the cause of the jam is visible in the form of worn rollers. Open the cassette tray mentioned in the message and look at the roller in the front centre (tray 2 is the built in cassette). It should have a wave-patterned surface. If it is smooth it may often work but it will no longer work well. There is a matching roller in the body of the printer which will be equally worn. Another roller immediately behind the one in the printer wears less but is sometimes replaced for convenience and the removal of doubt.

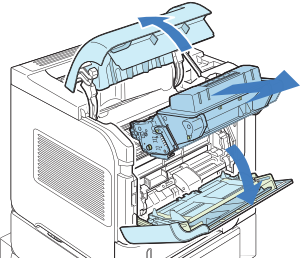

If the roller doesn't seem to be the problem, check through the paper path; take the cartridge out and look under it. Somewhat before the cartridge (towards the front of the printer) there is a metal flap with a green tab, lift that and look underneath for paper. The printer should be indicating where it thinks the problem lies: Tray 2, Top Cover, Rear Door or Duplexer.

There are two rather opaque areas in the LaserJet P4014, M601 and M604 series - as well as most other modern mono printers. Paper follows an S shaped path from the feed cassette to the output bin on top and the problems occur as paper goes round the bends.

Tray 2 Jams

As paper comes out of the cassette it is only being driven by the feed roller which is not very powerful and could be worn, so paper could be late. Paper has fed when it reaches paper sensor PS102 which is in the neck of the printer above the tray. At this point the main feed rollers, worked by a clutch, take over and will push the paper up to registration and then PS103.

The pickup, feed and separation rollers - and the lift motor in the tray - work together to get paper moving. If the interplay of forces isn't right timing goes wrong, paper doesn't arrive at PS102 and the printer stops. Alternatively paper does arrive but a bit too late and is caught with the tail end sticking out into the cassette. Users spot the paper going up into the throat of the printer and are only too likely to pull it downwards. Sometimes that dislodges the flag from PS102 leading to it permanently signalling a paper jam. It is difficult to fix, the sensor mountings are deep inside. If the paper seems wedged in there, take the cartridge out and pull and push the page up to the registration station; avoid pulling paper backwards; the paper path was not designed for things to move backwards.

Top Cover and Rear Door Jams

On machines like the LaserJet 4200, P4014 or M601 where it is easy take the fuser out you can get a view almost all the way through the printer. Once again it is better not to rip paper backwards out of the fuser but to feed it through in the intended direction of travel if possible. The LJ-4200 fuser has a green wheel to do this, the P4014 and M101 series are supposed to release the pressure roller when they jam. Either way it can be nearly as quick to take the fuser out and check it over to see why there is a problem. Be careful, a fuser that has just been in use can be very hot! Paper doesn't usually get jammed in the fuser as it is being quite strongly driven by rollers when it gets there. Frequent jams in the fuser area implies something wrong.

If the printer won't feed from the cassette without a problem try simplifying the feed path. Will paper feed from the multipurpose input tray? Will it feed to the rear face-down output tray but not to the top output tray?

Paper feed problems tend to have an erratic onset. They happen when a tray is nearly full, or nearly empty, or they are a nuisance at the start of the day. This is usually a sign that the feed and separation rollers are worn and need replacing.

Try turning the paper stack the other way up and if that doesn't work try it the other way round. HP recommend against the common practice of fanning the paper as it damages the edges and creates static charge

Look at the feed rollers. Modern feed rollers are usually a soft grey rubber and have a textured surface. If the rollers were once textured and have lost the pattern they won't work properly.

There is more on dealing with paper jams and several diagrams giving ideas what might be causing them here.

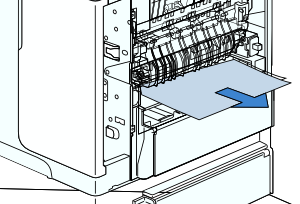

Tray 1

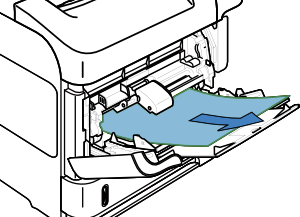

13.01.00 JAM IN TRAY 1. Tray 1 is the fold-down multipurpose tray on the front of the printer, sometimes called an MP tray. It is the simplest path through the printer and will take the widest variety of media such as labels, envelopes and light card. Tray 1 is therefore vulnerable to having marginal or unacceptable things put through it and sometimes failing. A common trigger for paper jams is use of inappropriate media - envelopes or labels not rated for laser printers for instance. Check the specification of the stationery used against that for the printer given in the user guide.With the envelope feeder cover, cartridge and fuser out it is possible to see clear through the printer. If there is nothing visibly trapped but the error persists then examine the paper path sensor positions; something is dislodged. Try simplifying printing by feeding to the rear drop down face-up tray rather than the top face-down tray. If paper jams are frequent even with ordinary office paper then the pickup, feed and separation rollers might be worn in which case kit CB506-67905 is what is needed. (The rollers are easily examined and replaced, a single screw releases the cover which lifts out to the left. A spring-loaded cover is over the separation roller). If the rollers have just been replaced and start giving this error they might not be seated correctly. The paper flag just to the right of the roller housing might not be moving correctly or the optical sensor might be dirty. The Diagnostics menu can test the tray 1:

- paper sensor - which should change an indicator on the display when it is pressed

- solenoid which should make an audible click when the test is run.

All the points so far can easily be checked by a user.

The service manual also suggests replacing the tray 1 solenoid SL102. This requires partially stripping the printer and is a job for a technician. Another possibility with recalcitrant faults is to replace the entire MP tray pickup assembly RM1-4563. The solenoid would be cheaper, except that HP don't seem to provide it as a separate part. What could be wrong with a solenoid? Examine the tip that holds the cam wheel closely, also look at the foam acting as an anti-residual strip. There is a frequent problem with HP solenoids that the anti-residual foam or strip decays leading to mis-timing and misfeeds. The solenoid may appear to work, but its timing is bad.

Tray 2

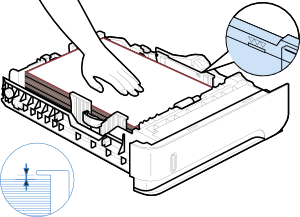

13.03.00 JAM IN TRAY 2. Tray 2 is the slide-in cassette drawer in the base of the printer. It is usually the most heavily used paper-feed tray in a printer. If there is a visible paper-jam in tray 2 note where it is and clear it. Paper jams can be caused by poor-quality paper or material that is out of specification, failure of the motor or sensors and things jammed in the paper path. However the most likely cause of an issue is worn pickup and feed rollers. The rollers are easily examined - particularly the one in the front of the cassette tray. The roller should have a substantial amount of texture - somewhat like the back of a hand. If the roller is shiny and has very little texture it and its partner(s) inside the printer need to be replaced. The kit CB506-67904 provides the rollers for the job. If the rollers have just been changed and this error occurs check that they are pushed home correctly.

Noting where the paper was when the printer reports a jam is helpful. If the paper has not moved at all, or just fractionally that would imply the pickup roller (RM1-0036) has a problem. If the paper has moved a bit further into the throat of the printer but is easy to remove that implies weakness in the feed-separation rollers (RM1-0037). If the paper has travelled into the printer throat and is a bit difficult to remove that suggests it has got through the internal feed rollers so it could be lazy action in feed-separation but could also be the internal feed rollers, and they will be difficult to deal with.

Be careful removing jams where the paper has gone into the throat of the printer above the cassette and seems stuck there. The paper sensor flag for PS102 (Pre Feed Sense) is in there and when paper is pulled downwards too sharply it can become dislodged. The paper flag is not easily accessible and could be a nightmare to get back into position. One possibility is to turn the printer off and try to pull and poke the flag back into place.

Intransigent faults are possible, of course. The paper path from tray 2 is a bit more complicated than that from tray 1. The tray contains two paper sensors - one for paper present and another for top-of-stack which controls the lift motor. At the right-rear of the drawer housing are three switches used to sense the type of paper loaded and the switch arms can give trouble. Paper is pushed upwards into the throat of the printer by the first feed roller and should trigger the PS102 pre-feed sensor and then pass through the feed rollers, whose timing is determined by a clutch. The paper should then halt and be straightened in the registration station. Any of the paper movement sensors might not be working. It is also possible that the tray 2 pickup solenoid or the feed-roller clutch might not work correctly. Run the various tests from the diagnostic menu, looking to see the sensors change as they are pushed. Listen for the audible click of the solenoid and clutch.

The points so far can be checked by a user - although running through the whole set of possibilities does take a bit of time. There is some help here.

A previous generation of HP laser printers gave trouble with the paper feed solenoid and this has continued into the P4014 series. The solenoid works in the sense that nine times out of ten paper feed works and that it can be heard ticking when operated from the diagnostics menu. The problem is that it doesn't always release correctly - giving a characteristic missed beat and a misfeed if the printer is asked to print ten or twenty pages.

A known point of failure is the cog and spring on the end of the paper feed shaft Z assembly RM1-4562 which can get knocked off; they are held in place by a very ephemeral plastic "E" ring. Recover the cog, spring and e-ring from the tray or floor nearby if possible - they are not available as HP spares. If they are lost then either equivalents will have to be found in a junk box or the paper feed shaft will need replacing, which is difficult to do and therefore expensive.

Some of the other parts that might be implicated are in the mechanical and low voltage electronics enclosure on the left of the printer and require work by a technician. HP suggest possibly replacing the solenoid again.

Tray X

13.03.00 JAM IN TRAY X. In its maximum configuration this printer series can take up to four more paper feed units, usually as one extra tray or a tower of three 500 sheet trays (3,4,5) and one 1500 sheet tray (6). Diagnosing problems with these trays is as for tray 2 with the added flexibility that the rollers, cassettes and entire drawer units can be removed and swapped around. As usual the most likely cause of a problem is the pickup rollers. Each tray has a motor and a clutch that can be tested from the diagnostics menu. Watch out for broken and damaged paper-feed unit connectors as well.

If a paper jam is persistent from one tray check what happens with another. It is unlikely (although not impossible) that all the rollers on a printer will be equally worn out. The tray 1 paper path is simplest so it is always worth moving the media that seems to be causing trouble there and trying it. Try ordinary office paper in a tray that gives problems.

13.20.00 JAM INSIDE <LOCATION>

Paper failed to reach the relevant sensor in the given time. Remove the misfed paper. If the fault recurs look for obstructions such as stray paper fragments or labels. Do a manual sensor test.

Locations are:

13.20.00 JAM INSIDE Tray 2 - Remove the cassette and check it and the drawer space for obstructions. Try a manual sensor test on the pre-feed sensor PS102 in the drawer space.

13.20 JAM INSIDE Top Cover - Remove the print cartridge and check the paper path beneath it. Look beneath the registration station flap, transfer roller area and at the paper feed assembly RM1-4548. Check the top of page sensor PS103 and width sensors PS106 and PS108 just after the registration rollers.

13.20 JAM INSIDE Rear Door - Open or remove the rear door and check for obstructions. Remove the fuser using the clips. Check the delivery sensor PS700 using diagnostics.

13.20 JAM INSIDE Duplexer - Remove the duplexer by lifting and pulling it from the rear of the printer. Paper sticking out of the top inlet implies the reversing motor and rollers in the back of the printer. Paper stacking out of the duplexer's tongue implies the inner rollers or something near the printer registration station. For more obscure faults check the printer's diverter and the mechanism called the delivery drive ( RM1-4526).

13.JJ.NT DEVICE WARNING

An external device such as a tray sent a warning.

The service manual says "No action is necessary" - obviously if it happens a lot it raises some questions.

13.JJ.NT PAPER JAM OPEN INPUT TRAYS

A jam occurred in an input tray. Quite what the difference between jam as an error and jam as a warning is eludes me at the moment.

Open the trays, check for misfeeds, then check the trays are properly closed.

Web Research

There are a lot of "13 errors". Querying Google with any specific error is likely to give different results. The user is not likely to put 13.xx.yy JAM IN TRAY xx

because that is not the message they are seeing (it gave About 57,400 results

on one test. Because HP use the same error codes across their printer range the result is a collection of recommendations for a miscellaneous range of printers many of them irrelevant.

Querying Google with the phrase 13.03.00 JAM IN TRAY X

from the manual (in quotes) gave About 615 results (0.27 seconds)

. Adding P4014

refined that to just 9. But as said that phrase isn't going to be used much.

Giving a more specific query - P4014 "13.03.00 JAM IN TRAY 2" -

gave About 68 results (0.14 seconds)

.

- fortwayneprinterrepair Good short practical article on what we call the Z-assembly problem where the cog has come off the arm that holds the pick and feed rollers. More on our site here.

- MindMachine Earlier version of the material I'm working on improving at the moment.

- laserprinterhelp Not a lot beyond the service manual suggestions of check the solenoid, clutch and feed roller. Seed material for a forum with no user comments at the present time.

- fortwayneprinterrepair on facebook.

- Another short extract from the HP manual intended as seed material.

- laserzone123 Copy of chapter 7 of the HP manual "Solve Problems"

- fortwayneprinterrepair pushing his article again via another forum - but there were several other fairly interesting articles so it's still useful.

- scribd Service manual provided as rather clumsy images.

- fortwayneprinterrepairpushing his article again.

- printerlab.com.hk Plagiarising our article on the HP LaserJet P4510 / 4515 series.

- laserprinterservices An advert accompanied by a list of P4014 error codes.

There are several points here:

- Higher positions in search can be gained by a variety of messages on forums all linking to a page; it's an old trick and it still works. For what it's worth I've put "nofollow" on the spammy links above because I see no need to promote them further.

- Users commonly become aware of a problem when they see an error code. Compared with the number of people offering parts which is often in the tens of thousands only a few are interpreting error codes - usually by plagiarising the HP manual

- printerlab.com.hk have had the cheek to plagiarise our information - naughty people.

Although 69 results

were suggested the remainder were all similar. This might suggest the error is not much seen and very little written about - but paper feed errors are known to be amongst the most common.

HP should be concerned about the P4014 user guide and service manual which suggest changing the clutch for paper feed problems but omit to mention changing the pickup and feed rollers. It is fair to point out that engineers should know the rollers are the first thing to think about but there is a danger of people just accepting what the manual says without giving it further consideration. Changing the clutch is a major job, so perfectly good printers could be going to scrap for want of £15 worth of rollers.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalogue. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.