HP Original Cartridges

Fusers and Maintenance Kits

Refurbished Fusers

Refurbished fusers have been lovingly restored to life - or that might be how the marketing bol*cks goes.

That means they are recovered scrap bought as "cores" for between £1 and £5 and given a new sleeve in a workshop in China. The sleeve is the part that noticeably fails.

Websites that care about printers might also suggest the heater, bushings and thermistors are replaced. Actually by "replaced" we think they mean "triaged". Ten or twenty scrap fusers are taken to bits, the good parts from them are picked out to make refurbished units.

If that lowers your confidence so be it. All refurbs are less reliable than originals. Sorry, they simply will be until the refurb industry improves its game.

Our refurbs come from a couple of spares distributors who we have found to be more reliable. However they buy in (or outsource) refurbs and they do have batch issues. We see a higher return rate than we get with HP originals. Not massive, but more.

In principle we think refurbishing fusers is a good idea. HP seem to disagree and don't make parts, specifications or methods available. So with a refurb you are relying on a combination of reverse engineering and pot luck.

We continue to sell refurbs because sometimes it is all our technician customers can do. The end-users won't shell out nearly £200 for a new maintenance kit and it's no good telling them that a new printer will cost them more in the end. So if the alternative is that a rather good printer goes in the skip to make way for a cheap to buy expensive to run replacement then we'll sell the refurb fuser.

Theoretically it is possible to make a refurb better than the original. If we are ever convinced that is being done we will promote it.

Error Message 50.1: HP P4014, P4015 & P4515 Printers.

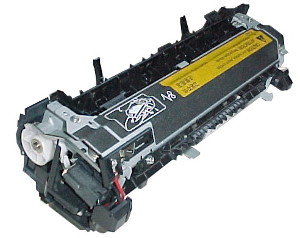

Laser printer fusers adhere toner powder to a page using a combination of heat and pressure. Error 50.1 suggests the heater has failed. The most reliable repair is to buy a new HP-badged fuser or perhaps a maintenance kit. A new fuser replaces the part that has failed. A maintenance kit provides the paper pickup and toner transfer rollers which are probably worn out if the fuser has failed.

Fusers can also fail without giving an error; toner doesn't adhere to the page in some areas and fragments of grey or brown fuser sleeve emerge. Other fuser errors are:50.250.350.450.550.650.750.850.9there is a bit more below.

At one time 50.1 on a laser printer was sudden bad news. These days it isn't so common; the P4014 series printers prompts with PERFORM PRINTER MAINTENANCE

as they go beyond 200,000 pages and expect it to be fitted by 225,000 pages - but that is optional. If you buy the kits when prompted you may never see a fuser error message. If you opt to just go on then one of the "50" messages will be the result. Just continuing might give quite a long free ride but it may be disconcerting and disruptive when the inevitable happens.

Fuser Errors

Fuser errors usually occur after printing many thousand pages. The printer control panel shows a message like "50.1 FUSER ERROR". In all probability the fuser will need replacing. This is quite expensive. For the LaserJet P4014 / P4015 / P4515:

- Just under £150 for a fuser alone (but it used to be £200)

- Nearly £200 for a maintenance kit (but it used to be £220)

A new fuser for a machine like the P4014 is more expensive than some new printers. On the other hand those cheap little printers are expensive to run, typically delivering a standard page for 2-3p. The P4014 and P4015 have big cartridges that deliver a page for between 0.7p and 1p per page, amongst the industry's lowest. The per page price for little printers tends to be three to five times higher, more if it's colour. If a fuser has worn out you clearly do a lot of printing so a cheap little printer would be a false economy. The good news is that changing the fuser in a P4014 series machine is easy to do, little more trouble than changing a cartridge. You don't need a screwdriver, or to pay an engineer to do it and if you get a maintenance kit the printer will be good for just under a quarter million more pages.There are instructions here.

Curiously, the price of new fusers and maintenance kits has fallen a bit over the last couple of years. This seems to happen with HP's big laser printers. We suspect it reflects HP and their distributors gearing up to meet market demand. The first distributors with stock can get a bit of a premium. It might also reflect competition from refurbished fusers (which we can discuss).

If you are happy to buy a new fuser or maintenance kit without further reading by all means do so, we advertise them alongside and in the catalogue here. However if you hope to save money or just to learn why the fuser might have failed then keep reading.

What Fusers Do

Fusing is the final stage in the laser-printer process. The fuser heats and presses toner powder to make it adhere to the page. If you know how laser printers work, skip this section, web-sites cater for varied skill-sets

.

Toner powder is laser printer "ink". Toner is a fine-ground plastic dust with the consistency of cornflower. In the P4014 case it's a mixture of polyester and magnetite with a little wax and carbon black. Toner materials are strongly attracted to static electricity.

The print process focuses around the imaging drum; this is inside the print-cartridge on almost all HP laser printers, together with the toner and developer. All-in-one cartridges are a key bit of the economics of an HP printer, it is easily changed and reduces the need for engineer call-outs. About 70% of the parts that go wrong are changed with a print-cartridge.

The printer charges the drum using static electricity then as it rotates it is selectively discharged by the laser, leaving a latent image in electrical charge. Next the drum rotates past the developer, which carries a layer of toner. The static fields attract toner powder which is then pulled onto the drum. Further in its rotation toner is pulled off the drum and onto the page by the transfer roller. The fuser softens the toner and sticks it to the page using pressure. More here.

There are many possible designs of fuser but only two are common:

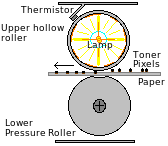

- Traditional fusers use a pair of rollers to heat and compress the page without smearing the toner. The top roller is a rotating aluminium tube coated in Teflon and heated to a couple of hundred degrees centigrade by a halogen lamp running down its middle. The lower roller is usually made of stiff heat resistant rubber material (iron oxide filled silicone). The top roller has a couple of sensors mounted on it, a thermistor senses the temperature and maintains it by turning the lamp on and off every few seconds. The other sensor is a cutout or thermal fuse that will keep the fuser temperature from rising dangerously high. This has beeen a time honoured and widely used design. A disadvantage is that it takes some time to heat the rollers up to working temperature - so if another print job is expected soon it will be kept hot, wasting power. A little printer can get through 10kwh per week on standby. (FS-680).

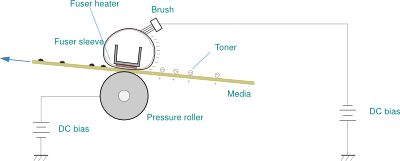

- Instant-On fusers were invented by Canon and HP. The top roller is replaced by a heated ceramic bar but that on it's own would smear the page. To prevent this the bar is loosely wrapped in a Teflon sleeve which rotates with the page. The ceramic heater is powerful, it can turn on and heat the sleeve and the nip-point with the roller in less than ten seconds, so it is only heated to temperature when needed. A typical printer is used intermittently so all that standby energy is saved. Almost all HP and many Canon printers use this principle. Lexmark now use "belts", there are a dozen variations on the theme.

Why Fusers Fail

Fusers wear out. The Teflon coat on the roller or sleeve gradually loses its non-stick properties and then toner from the page sticks and builds up. Heavier page cover like dark pictures or strong black banners degrade the fuser sleeve more. Material fatigue due to hot-cold, pressure cycles and accelerations build up. Ionic and triboelectic reactions weaken the repulsion between fuser roller and toner. The hotter a fuser runs the more it is likely to fail, the heater will be on more, and nearer its limits. Many other materials are near their limits too, like the silicone material of the pressure roller and its glass or fibre filled plastic bearings. Heavier media like cards and labels need hotter fusers, cause uneven pressure and will impose extra wear.

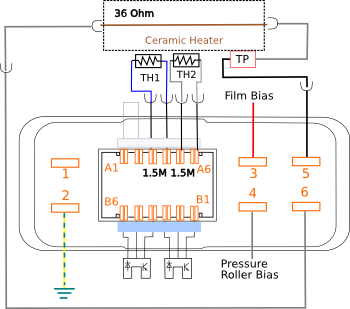

50.1 generally means heater failure. The heaters in recent HP laser printers are ceramic bars with one or more resistive traces made from silver palladium, ruthenium oxide or perhaps just good old carbon black and ceramic paste (so patents suggest). Its a high power thick film resistor. In this case there are actually a pair of parallel tracks with a joint resistance of about 36 Ohms delivering perhaps a bit over a kilowatt when turned on. If the heater weren't cooled by the constant passage of paper and the pressure roller it would light up orange and last several seconds before it burned out.

In this case the "hot roller" around the heater is a thin metallic sleeve with a non stick coat. Coatings on the sleeve can include an adhesive layer, a conformal layer (perhaps silicone) and a non-stick coat (perhaps PTFE). To prevent the metallised sleeve contacting the resistive element in this case the ceramic bar has its heaters on the reverse surface so the bar itself gets hot. Its a dark material, probably thermally conductive.

Resistive heater and sleeve need to be in good thermal contact. This is partly achieved by pressure but that isn't sufficient. The contact zone is lubricated by a high temperature conductive grease. If the consistency of metal, lubricant and glass aren't right the ceramic will run too hot whilst the fuser will be too cool.

Thermal cycling will weaken the heater over time but a power surge or simply turning it on will take one or both tracks out. Interestingly the fuser life can be controlled a bit. Firmware 20100113 04.060.7 has a phrase on the lines of Modified fuser power profile for reliability

.

Fuser failure might just be treated as "one of those things" with some cheap printers. Manufacturers use the fuser as a life-fuse, forcing people to buy a new printer (little printers can be fixed, but spares and labour costs mount up). Better printers have the fuser as a replaceable module. The P4014/P4015 series fuser is very easily changed; it is a simple plug-in unit. Changing the fuser adds less than 0.1p to the price of printing a page. The price of toner is far higher and costs between 0.3p and 3p per page depending on machine and brand. When people are faced with buying one, fusers for big printers can appear expensive but the cost is trivial in the greater scheme. In this case the fuser cost is 0.1p per page and HP Original toner as little as 0.7p per page.

Fusers wear out just as inevitably as cartridges use toner. Quite typically a fuser lasts about 10 times as long as a large cartridge - 20 times as long as a small one. With P4014 and M601 series printers the firmware will predict the failure and at 200,000 pages or so will prompt the user for a maintenance kit. The supplies status page and the Information > Supplies-Status

page give a bar graph showing when a new kit will be required.

With HP printers, people are at liberty to ignore the maintenance kit message, there is an option to clear it for a further 10,000 pages and it is possible to set longer intervals. If you do those things then you will wind up with a 50.X message. That probably means the fuser has come to the end of its life. It is just possible you might be able to continue anyway, the possible remedies are dealt with shortly.

50.X Fuser Errors

Fuser problems are sometimes described as "50.X Errors" because "50" and another digit is what most HP LaserJet printers show on the control panel. The number originated with the original LaserJet in 1984 and that was widely imitated. Many printers use the same message which might sometimes cause confusion, but across the printer range the fusers and problems they raise are quite similar.

Fusers for the LaserJet P4014/P4015 can fairly easily last beyond 225,000 pages of print. Whilst that is generally true there isn't an unconditional guarantee. Like car tyres, fusers generally last several years; it is possible to wreck them in a few weeks.

Heavy black print, thick paper, envelopes, labels and plastic media are all likely to exact a toll from a fuser increasing the wear and damage and shortening its life.

Fusers are straightforward at one level -essentially a hot mangle. In detail the process is quite complicated. A ceramic rod with one or two thick-film resistors under a glass film and a non-stick sleeve is violently heated whilst a stream of cold paper at 1 sheet per second is pressed hard against it. The fuser needs careful design so that it can't set fire to the paper (which was a problem in 1960s copiers). The temperature has to be sufficient to make the toner tacky so that it sticks to the page, but not so high that is sticks to the hot roller. It has to achieve this with material ranging from bank-paper to card and transparencies and with toner cover ranging from nothing to sometimes as high as 90%. The printer has to cope with users who have no idea of these complexities telling it to do the wrong thing by setting a tray for heavy media then putting ordinary office paper in; it will run too hot and be more likely to get "50.1".

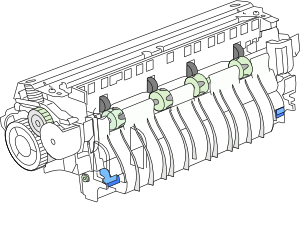

Customer Replaceable Units (CRU)

HP refresh their design portfolio every few years. The LJ-4250 series had been on the market for about 4 years when the P4014 series were introduced in 2008. They were replaced by the M601 in 2011 (- different name, similar look and innards) and by the M604 series in 2015 (different look, similar innards to the M601).

One big change quietly introduced was the loss of that contact an HP-authorized service or support provider

message. All the parts of the maintenance kit formally became "Customer Replaceable Units" - so did the formatter, cassette tray and the accessories. This carries the idea of a cartridge forward to cover something over 95% of what will ever need doing to the printer.

There are still areas of the printer such as the PSU, motors and gear chain, and the DC controller that are engineer changeable - but these actually fail very infrequently.

All IT equipment ultimately has life limits, but printers can be long lasting and there is probably no reason why the P4014 and its successors should ever die - excepting that HP might withdraw parts. These things can run for a decade or more and produce millions of pages giving very little trouble. Printer and maintenance costs fade to insignificance, leaving paper and print-cartridges to be considered.

User Guide

For all 50.x errors the HP P4014 series User Guide says in its "Control Panel Messages" chart (p285) :

- 1. Turn the product off and then on.

- 2. If the message persists, contact an HP-authorized service or support provider.

The fuser in printers like the P4014 is supposed to be user replaceable but they suggest you to call an outsider; that is disappointing. In some cases the cost of a call-out could make repair uneconomic and the printer will go for scrap.

At least in the Service Manual they are a bit more informative.

- 50.1: Low fuser temperature

- 50.2: Fuser warm-up service

- 50.3: High fuser temperature

- 50.4: Faulty fuser

- 50.5: Inconsistent fuser (verify voltage model)

- 50.6: Open fuser

- 50.7: Pressure release mechanism failure

- 50.8: Lower fuser temperature

- 50.9: High fuser temperature

and suggests the following:

- 1. Power cycle the product to determine if the error is persistent.

- 2. Verify that the correct fuser model is installed in the product.

- 3. Verify that the correct voltage fuser is installed in the product.

- 4. Verify that the fusing assembly is firmly seated in the product chassis.

- 5. Verify that the connection to connector J82 on the DC controller PCA is firmly seated (P4014 series only).

- 6. Inspect the fusing assembly connectors, at the front of the assembly, and the connectors on the high-voltage power supply PCA. Look for bent pins or debris. Clean or straighten the pins if necessary.

- 7. If the error persists, replace the fusing assembly.

- 8. If the error still persists, replace the high voltage power supply.

More explanation than given in the user guide or service manual might help.

"50.1" is usually clear enough; the fuser could not heat up. This is probably the end of the fuser; although it might be possible to replace the heater a close look at the sleeve will probably suggest it isn't worth the trouble unless you are going down the route of fixing everything in-house.

It is just possible that the power-supply or the DC-controller might be to blame but to check that meter the fuser heater elements.

"50.5" means you are trying to use the wrong fuser (the 110V device won't work in a 220V machine and RM1-8396 for the M601 apparently will work but will give errors).

The other errors are more questionable, possibly recoverable. They are all capable of disappearing - or of meaning there is something rather worse than a fuser wrong like the power supply board or DC-controller. We'll return to those issues below.

Errors Without Messages

Fusers can go wrong and initially give no error at all.

If the Teflon foil shreds but is still largely intact then non of the printer sensors will detect an error - at least at first. The user will find marks on the page and toner not adhering to the page properly and might find some bits of foil in the output tray.

Less self evidently fusers can give smeared print. Instant-on fusers use a non-stick sleeve around a ceramic bar heater to prevent print smearing as the page touches the heater. The sleeve is lubricated to make sure it turns freely, but it has to do this at high temperature. Lubricants that work well at high temperature are an interesting science. Fuser refurbishers have sometimes got the lubricant wrong. To see if the fuser is causing print problems use a stop test.

If the lubricant has settled in an odd pattern it is possible for the fuser sleeve to stick, creating a paper jam. In printers like the P4014 and M601 the fuser has a separate drive motor and cog-chain. In principle the DC controller should notice if the fuser is unable to turn properly and the59.2 error should be raised; however there is evidence that this doesn't happen so jams are possible.

The fuser also carries one of the paper detection flag and photo-interrupters, so it can give paper feed errors if this fails.

Errors Messages and Speculation

Dealing with computers, fault finding and problem solving is often largely a matter of speculation and inference - quite contrary to the logic and certainties sometimes presumed to dominate.

HP know what their error messages mean; however they don't always make it at all clear in the manuals. In fact, as we note above, it is left totally opaque in the user guide and what the service manual says is just a bit more revealing. There is a bit of evidence that the design teams have some leeway in what faults get which messages and that information might not filter through to the teams working on documentation and customer support.

Research on Internet forums does makes it clear that people often respond to the prompt "50.X FUSER ERROR" by buying a new fuser; its an expensive item and it isn't always the right answer. It is even possible to install a new fuser and have it damaged as well - (its happened to me on one occasion). People who sell new fusers don't find much profit in it (HP gets most of the purchase price) so we don't want accidental returns. If HP don't reveal precisely what the messages mean we have to do a bit of research, make some assumptions and try to infer what is going on.

We note with amusement that with firmware 20100113 04.060.7 some new fuser error codes added to aid troubleshooting. The Firmware release guide didn't elaborate on this and the new code are probably the rather odd ones in the M601 service manual. But they made the service manual obsolete. How is anyone to track this CrΔp ?

- 50.1 -fuser didn't come to temperature, probably heater failure but see below .

- 50.2 - warm up timed out. Temperature rose but not enough. Power supply or fuser?

- 50.3 - warm up went over temperature. Blocked fan, thermistor, overvoltage?

- 50.4 - often specifically used for fuser heater failure.

- 50.5 - wrong fuser - either the wrong voltage or wrong model (M601 in P4014?).

- 50.6 - open fuser - probably means open circuit. (why not 50.1 or 50.4).

- 50.7 - pressure release mechanism failure (detected by PS699).

- 50.8 - low temperature sub-thermistor. Uneven heating due to bad media or failed heater.

- 50.9 - high temperature sub-thermistor. Uneven heating due to bad media or failed heater.

Looking into the power connector on the fuser the power circuit is on the right. If a meter probe shows no conductivity (or nothing like 36 Ohms in the UK - lower in the US) one or both heater traces are dead. If the resistance is around the correct value then you have a problem - it doesn't seem to be the fuser, so there might be an issue with the power supply or DC controller. In that case, don't buy a fuser! Check cable seating first.

50.1: Low fuser temperature.

50.1 Low Fuser Temperature Error usually means the fuser stayed cold when power was applied. The implication is that is has a damaged heater circuit, and most probably the heater element(s) in the fuser itself have blown.

The fuser heater was given power but the thermistor monitoring circuit showed no warm up. Since thermistors don't often fail the fault is more likely to be the heater. If the fuser is taken out of the printer it is often stone cold - (be careful because if the thermistor did fail then the fuser could be very hot!)

Being absolutely sure that the heater really has failed needs a multimeter to measure the resistance. There are actually two heater traces on the P4014 fuser (many older fusers have one trace, some now have three or more). The wires feeding them come out on either side of the fuser and go to two or three of the larger pins.

It is logically possible for the fault to be the control circuit and not the heater, however that seems unusual. If there is reason to doubt then measure the resistance of the fuser heater - blown heaters will be open crcuit. It is actually quite difficult to test the heater control circuits as they are buried in the power supply.

In principle it is possible to replace the fuser heater and indeed if you are refurbishing fusers this is one of the things that should be done. For the average user site changing the fuser heater isn't practical. The fuser is a complex assembly, stripping and rebuilding it on a one off basis takes about an hour, if you can get reliable parts.

Fuser heaters aren't available from HP. There are people selling fuser heaters on eBay and Alibaba, (eg, here). Some may claim to be manufacturers original parts but there are far too many; raising suspicions about quality.

When a fuser heater blows it could be caused by a power-surge or by a malign wear pattern from the sleeve. Usually the printer has been in use for some time and probably used beyond the 225,000 page maintenance interval. If you look closely at the sleeve it is probably worn out as well.

Web Research

In 2013 I tried querying Google with P4015 "50.1 FUSER ERROR"

in quotes; this gave About 6,500 results

which is lower than might be expected for the most frequent error, perhaps because technicians are only too familiar with it.

- fortwayneprinterrepair Good introductory article by a working engineer. Not much information going beyond what most of us know. Quite a bit about direct power supply which is will be more relevant on US 120V power. Nothing about the sub-thermistor, pressure adjustment photosensor or about replacing parts. Wrong about there being nothing compatible (M600 and Nupro). No diagram. (OK I'm being picky)

- Precision-Roller YouTube video on installing a mintenance kit in the P4014.

- printerrepairsupport Brief, mentions turning off and on and power source, doesn't discuss any part numbers other than RM1-4554 but no mention of CB506-67901 or RM1-4579. No diagram. Blog with no comments.

- thelaserguys Rather generic page about "50 Service Errors" primarily aimed at the 4200 series so a bit out of date. However they do have a good article on metering suspect fusers

- fixya Rather generic page covering a great many printers in Fixya's usual cheerfully brief (not to say innadequate) style. Typically 1702 people viewed a page 2 people found it helpful.

- helpowl More adverts and offers of miscellaneous irrelevant dowloads.

- fortwayneprinterrepair puffing his article above.

- mindmachine our own article on the P4515 printer.

- depot-america seriously out of date article unless you still have LaserJet 8000 series printers.

- printertechs General laser printer troubleshooting page. Slightly disappointing material because printertechs are often very good.

If your laser printer shows "50.1 FUSER ERROR" it will usually be a genuine fuser heater fault. That can be verified if the heater is open circuit.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog.