HP Original Cartridges

Fusers and Maintenance Kits

Refurbished Fusers

HP sell fusers as a maintenance kit, as fuser kits with instructions and as bare fusers. They don't currently sell parts for the fusers. With a couple of small exceptions like the 5L they never have done.

It used to be fairly easy to fix a fuser, needing some unusually shaped halogen lamps and Teflon coated rollers.

Things are more difficult with the "instant on" fuser. It saves a lot of energy compared with its predecessor - over 10 kilowatt hours per week, but the parts it uses are unusual and hard to source reliably.

In terms of greening the economy we think doing things at a local level is better. Cartridge and fuser building might be better done locally. Ten or twenty cartridges are used for every fuser so whilst there is a network of cartridge shops doing refills (remanufacturing has about a third of the market) there are fewer prepared to tackle fusers.

Amongst HP's reasons for not making fuser spares available we suspect are tech support and logistics issues - exactly the same points we have to consider. The heaters are thin slivers of ceramic, very easily broken. They need the right silicone glue to lock them in place and high temperature lubricant. The connectors have to be good and firmly in place. Selling heaters would potentially be a hassle.

That is probably why the P4014 heaters we do see for sale are $16 in China and £28 trade in the EU. Nobody is going to sell without a margin and by the time a heater priced like that has been shipped in a rigid container the price is going to be nearly that of a refurbed fuser.

So replacement heaters is something we have considered. If anyone who makes ceramics like this want's to contact us we'd certainly consider selling them. But no promises - and we'd prefer HP to give a lead. HP have the key knowledge, we are merely researchers and spares vendors.

Error 50.2: HP P4014, P4015 and P4515 Printers.

Laser printer fusers adhere toner powder to a page using a combination of heat and pressure. Error 50.2 suggests the fuser can't heat up properly. This might be fuser failure but could also be a power supply issue. Plug the printer directly into a wall socket, not into an extension. Try turning off, wait 20 minutes then on again.

Other fuser errors are:50.1 50.350.450.550.650.750.850.9

50.2: Fuser Error.

50.2 Fuser Warm Up Service or fuser warm up timed out. When the printer tried to heat the fuser the temperature measured by the thermistor did not change sufficiently in the time allowed. This problem seems less frequent than "50.1" and a bit less common than it used to be on older printers. It seems that the temperature does change when this fault occurs, just not sufficiently. The fault is a bit more difficult to diagnose because more details of the circuit are involved.

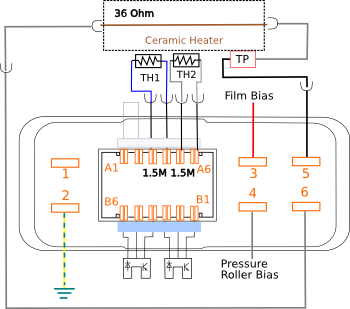

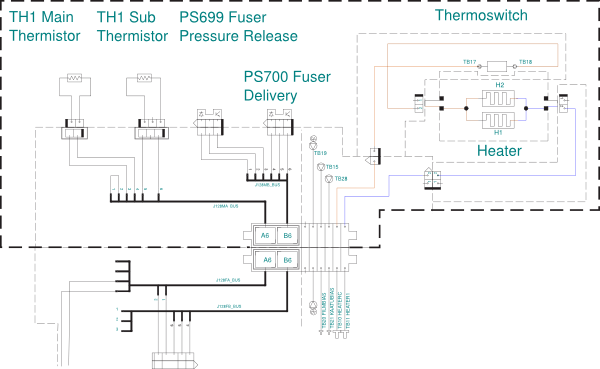

There are actually two heater circuits in the P4014 series fuser but both the heater traces and the circuit diagram show them "common" at the fuser connector. If either side fails that will leave the fuser able to warm up but not reach the working temperature needed for full-speed operation from cassette 2. "50.2" might not be just like 50.1 but it would spell doom for the fuser.

However it is also possible for the fuser not to reach temperature because the supply voltage is inadequate in some way. Heat falls away rapidly with voltage (square law), so a power brown-out may allow printer electronics and motors to run but be insufficient to get the fuser to temperature.

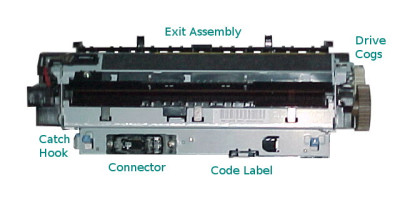

This shows the connector on the fuser viewed as you look into it. The heater connectors are on the right, the pins are labelled 5 and 6. 220 Volt fusers like the RM1-4579 have a resistance between the pins of about 36 ohms. If one track of the heater has gone it will be markedly higher. Thermistors at 25C seem to be about 1.5 meg.

110 Volt fuser resistance my be around 9 Ohms (power is square-law). Thermistors will still be about 1.5 meg.

Printers should be plugged directly into a wall outlet, not into an extension cable and certainly not into a UPS. HP and many other sources stress that low voltage issues can be caused by extension cables. Most buildings were built and wired long before IT equipment became commonplace and extensions are used to provide power for clusters of computers. In the US power is supplied at a nominal 120 volts or so. The heater in a fuser needs about 10 amps of power to reach temperature - which is near the limit of 15 amps can be drawn from a NEMA-5 outlet. The high current can pull the voltage down. This problem is probably more common in the US than in Europe and the UK where the 220 Volt supply voltage means the printer only needs to draw about 5 amps. However the argument still holds - if you have a 50.2 error try plugging the printer directly into the wall.

Readers might be surprised but in our own office we found a 2 volt drop between a wall-socket and the farmost extension with nothing but computers and monitors plugged in. That is a 1% loss of power in room cabling alone. (OK some of that could be power factor).

Fuser Circuit Operation

"50.2 error" is a problem because there could be other causes. Operation of the circuit goes along the following lines.

The printer begins its initial self test and warm-up at power on. According to the Service Manual the printer temperature is measured using the environment sensor thermistor on the fan housing and the DC controller estimates how long the fuser should take to come to temperature. Power for the fuser is actually switched by the power supply board, largely under instruction from the DC controller. The thermistor on the fuser feeds back the current temperature to the DC controller. There are three main things in the thermostatic feedback loop - fuser, DC-controller and power supply, but the environment sensor is apparently taken into account as well.

With some printers a warm up problem might be caused by the environment thermistor. If the printer has been moved from a cold to a hot room (or from a warm place to a cool one) then the environment thermistor will be wrong and the fuser warm-up timing will be out as well.

The fuser has two thermistors, one called the TH1 main thermistor offset about 25mm from the centre-line and another called the TH2 sub-thermistor almost at the paper edge.

Most likely only the main thermistor is taken into account at this point. It is pressed down onto the heater by a spring. If it does not make good contact it won't register the temperature rise.

Look for weird things like material stuck to the sleeve which might stop heat travelling correctly or distort the material so it doesn't sit correctly. A traditional fuser could get material stuck under the thermistor so that the temperature on the roller was too high whilst that on the thermistor was too low. However we don't think that is likely for the P4014 fusers because the thermistor is on the heater bar inside the sleeve.

If you think the fuser heater that failed raises the obvious question - rather than replace the fuser can we just get another heater. The answer to that is a "qualified yes". There are people on Alibaba and eBay selling parts for the fuser. Some may claim to be original HP product. Most do not look quite like the HP product and we suspect HP would disapprove of any of their suppliers selling spares through any channel but them - and HP do not currently sell fuser parts.

Furthermore the fuser heater is deeply buried in the mechanism so an attempt to get at it really means a complete "refurb" of the fuser - which is time consuming and error prone.

Diagnosis & Repair

50.2 is quite likely to be fixed by unplugging the printer, leaving it for half an hour so the fuser cools down then trying again. Meanwhile get it plugged directly into the wall. Cycle the printer power a couple of times before concluding that a new fuser is needed. Try metering the heater circuit and thermistor to find out if it is good.

If the problem persists another point to check might be the printer driver fuser setting. The P4014 has four fuser settings (for each media type) the idea being that the user can select the one with best results. It is possible that firmware might be confused by particular mixes of settings, heavy media and unfortunately low voltage.

If 50.2 were to occur whilst printing was in progress that might imply the media is cooling the fuser beyond its ability to heat up. Media settings might be wrong.

HP added an extra "high 2" fuser mode with firmware 20100212 04.070.7

. As speculation, this might improve performance with heavy media and if there is an issue with 50.2 might be worth investigating.

Web Research

In 2013 I tried querying Google with P4015 "50.2 FUSER ERROR"

in quotes; it gave About 70,400 results

, suggesting this is a fairly popular topic.

- fortwayneprinterrepair Brief article specifically about the P4014 series and 50.2 errors

- printerrepairsupport Another article specifically about the P4014 series and 50.2 errors, rather similar to the first.

- HP_forum. Question is relevant but answer just says "get it repaired under warranty", which won't be much help for owners of the P4014 series now as the warranties expired. Also, HP say fusers are consumable, so will they hour warranty on 50.2 errors?

- spiceworks article about ghosting ultimately cured by swapping a third fuser. I didn't feel the advice was very sound. Should have done a stop test.

- fixya Answer ripped from somewhere else ?

- feedreader.com Nearly useless.

- laserzone123 Boilerplate rubbish trying to sell refurb fusers for $150 with $50 charge if no core exchange. Refers to the P4015 as having an upper fuser roller, it has a sleeve instead.

- printertechs article suggesting that not having the fuser internal connectors onto the heater ceramic pushed home could give the 50.2 error on a range of HP printers. A good suggestion.

- laserprinterhelp General article on the P4015 series

- fortwayneprinterrepair puffing the article that heads this list.

- marketpoint.com Almost nothing beyond cut and paste from the service manual.

- fixyourownprinter forum stuff directly relevant to "50.2" on the LJ-4200 but with some relevance

- mindmachine article I'm working to improve.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog.