| Band-printers Printers > Bandprinter | Navigation Icons Guide

|

| Band-printers are part of a family of printing devices called impact printers – printers that rely on transferring ink using a hammer. The impact printer design has a long history and has proved very succesful. The basic mechanism uses a fabric ribbon coated with ink. When the material is placed under pressure the ink transfers - so if the ribbon is hit by a metal type-face ink transfers across to the paper. The design first appears with the typewriter and ticker-tape in the later 19th century. Typewriter technology was used by the computer industry – some early computer printers were just modified teleprinters and typewriters. The Teletype KSR33, IBM Selectric golf-ball and Friden Flexowriter were computer industry work-horses for many years. The basic problem was that this technology was slow, under 20 characters per second – at best a half-page per minute. In the 1970’s impact printers expanded to a major industry, but they have been overtaken by other designs and are now a minor part of the market. |  |

Bandprinters appear to originate as the "Flying Typewriter" made by the Potter Intrument Co of Great Neck, New York in 1952. Time Magazine on 10th March says it is "designed to keep pace with the flying thoughts of electronic computers. Instead of working laboriously, one character at a time, it prints whole lines at once, 300 lines per minute on a paper band." The machine was apparently a spinning disk with the characters on it's rim and 80 hammers arranged to strike the characters as they passed. ![]()

There is a "Survey of Mechanical Printers" by J.C. Hosken on the web dating from 1952. It has pictures of the Potter Flying Typewriter and other curious instruments like the ANelex Synchroprinter.

Band-printers and dot matrix printers are the only remaining common impact printers. Both survive because of their robustness high speed and low operating costs.

Band-Printers

Market Position.

| Band-printers have been used in large organisations because they can achieve high-speed output at low page cost. Band-printers themselves are among the most expensive printers on the market, they can cost in excess of £10,000 for a new machine, and several thousand pounds second-hand. On the other hand the combination of high speed and low cost output justifies the high purchase price if a lot of printing is to be done. Band-printers and their relatives drum-printers are sometimes collectively known as line-printers, they print a whole line in one go. Parallel dot-matrix machines are sometimes included in this class because they are very fast - although they don't actually print a line at once. The DOS / Unix "LPR" port gets its name because at one time line-printers were the industry standard.

|  Fujitsu 3043 - Typical Bandprinter |

- it potentially makes the cost of each copy lower still

- it provides a forensically verifiable carbon copy of the original.

Bandprinters typically output somehwere between 1,200 and 3,000 lines per minute. Speeds haven't changed much since the 1970s. The printer has to impact hammer, ribbon and paper. At 1200 lpm the impact is 20 times per second, but the actual duration of the contact has to much swifter - lasting perhaps a couple of thousandths of a second. The limiting factor on speed is packing enough fast acting electromagnets into the space.

Unfortunately bandprinter output is usually ugly to look at. A typical machine can only manage a limited repertoire of 64 or 96 characters, and they are limited to output at 10 characters per inch at a fixed pitch. Crude graphics are achieved by subterfuges, like using arrays of asterisks, or overprinting one character with another to give shading effects. (ASCII-art originated on bandprinters). Users don’t want high quality so they economise on ribbon changes and maintenance - this further spoils the look of printed pages.

In practice much of the bandprinter output people see is faded because the ribbon is exhausted, and the hammer-banks are often ill-tuned so that some characters are barely legible. As bandprinters get older wear in the hammerbanks makes them more difficult to tune with precision. Since the bandprinter is very big, tuning often has to be done by field service engineers and it is not a favourite job.

During the last decade the band-printer has lost market share to high speed dot-matrix devices, to the shuttle printer and to high speed laser printers. There have been changes in work patterns, which move operations away from IT centres and their band-printers towards local offices with laser and inkjet machines.

Advantages.

Band-printers are built to an old and trusted design and they can have a very long service life. There is no cheaper way to transfer ink onto paper than using the impact method. If what is being communicated is straight forward - invoices, delivery notes and work-sheets then the band-printer will do the job most reliably and cheaply.

The market for bandprinters has certainly declined but many are still in use. They are still available new - but not in ordinary computer stores.

Models.

Machines like the DEC LP37 (now HP), Fujitsu M3043, Dataproducts FP series and IBM6252

The Wescode 2000 BP has a full speed of 2,000 lines per minute and a lower speed of 1,600 lines per minute producing OCRB machine readable codelines. Writing 2 lines on cheques or tickets 3" across it can produce 18,000 documents per hour - 5 per second. If the stationery can be made 2-up then speeds double.

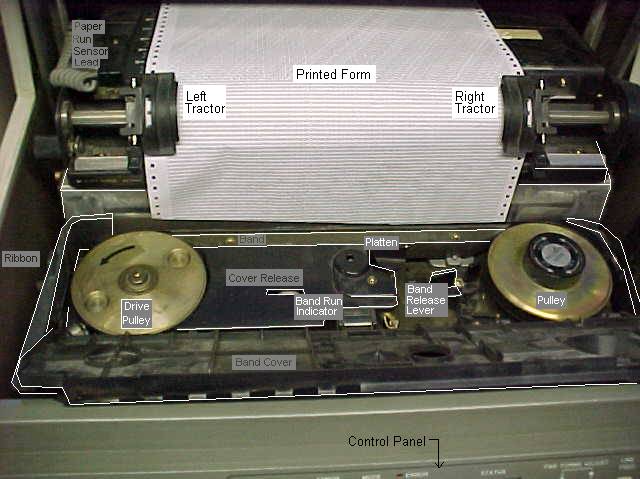

This picture shows some of the main components of a Fujitsu M3043 printer. The band and it's two pulleys can be seen in the foreground. The hammerbank is behind the paper. The band cover is released by rotating a thumbwheel - this simply makes a bit of delay so that users don't come into contact with the moving band.

The knob on top of the right pulley adjusts it's angle slightly. This changes the running position of the band, it can be checked in the band un indicator.

This model uses a cartridge loading ribbon. The bulk of the ribbon is under the band cover in the picture above but it's arms are highlighted stretching towards the paper.

The general principle of a bandprinter is that paper is carried through a print station on forms tractors. The print station consists of a platen, hammer bank, print band, the ribbon and ribbon shield.

The platen is often nothing more than a straight, solid bar of metal with a polished face. The paper travels across the platen which is mounted so that it will represent one line of print across the page. The platen’s job is to cleanly absorb the impact of the hammers.

| In principle there is a hammer for every possible print position on the page. This means that to achieve 10 characters per inch there must be 10 hammers per inch across the paper, and since standard computer paper is 14" wide there will usually be 132 or 136 hammers. To achieve a print-speed of 1200 lines per minute each hammer may need to move more than 20 times per second, and achieve a reasonable impact on band, ribbon and paper. Hammers may need to be capable of striking the print band 20 times per second, but their actual movement may need to be of much shorter duration because the band is a moving target. |  |

Achieving rapid movement requires a momentary drive power of 200-400 watts or more. The hammer coils need to be quite substantial to deliver this sort of power, and this is difficult if the entire assembly is to be 1/10th inch thick. The spacing can be relaxed to a more comfortable 1/5th inch by arranging hammer mechanisms alternately up and down. The Fujitsu M304* family has eight hammer banks, four suspended down and four held upright, designed so that the hammers are aligned in a straight row across the page. Perhaps contrary to expectations, the hammers do not need to move much, they travel forward only 1/10th inch (2mm) or so, what matters is the sharpness of their impact. Hammer power levels are high, but the duty cycle is short.

| One curiosity is that the hammer bank is often behind the paper, whilst the print-band and ribbon are in front. The shock-wave from the hammer travels through the paper - which may be 6-part multicopy - before it impacts on the ribbon and the band. Hammer banks with 136 mechanisms look complicated, but of course they are just the same device repeated. Hammer banks also look rugged - there is a lot of heavy metalwork. The heavy metalwork is needed to take away heat from the solenoids and to absorb the momentary force of their operation. Although the hammer bank looks chunky it is also a piece of precision machinery and needs to be treated carefully. One of the problems with hammer banks is that although they are precision mechansisms they usually can't be oiled. If the mechanisms were oiled, paper dust would become trapped in the oil and turn into sludge, which would unpredictably slow the hammer flights. |  |

Hammer Shuttle.

Some older printers had half or quarter the number of hammers across the page. In this case they typically used a shuttle mechanism to move the whole hammer bank left and right on successive operations. Halving the number of hammers halves the print speed, but only cuts the price a bit because there is the added cost of the shuttle mechanism.

The lack of oil is a problem when a printer is put into store. If a printer is left in a damp or even just "condensing" environment for any time the tiny metal particles that build up on working surfaces rust and the hammers seize. If a hammer bank has to be stored it should be hermetically sealed with moisture absorbing crystals. If this can't be done then a coating with light oil is less of an evil than rust. Oil can be washed off with isopropyl alcohol, rust does lasting damage.

Print Band.

| The print band gives the bandprinter its name. It is a flexible steel band typically about 40" long (just over a metre) with the character-set embossed on its surface. Since the character set is usually only 96 characters long the whole lot might be repeated four times along the band. The band will also generally have a timing- track of marks for each character position embossed on it or cut in it. An index mark is usually a double mark that shows the control logic exactly where the beginning of the band is. The band rides on two pulleys, one of which will be driven by a motor. The band doesn't need to travel particularly quickly - although beware - they can easily inflict a nasty cut so there is usually a cutout switch in the cover. |  There is usually one timing mark per character and a double mark as an index. 96 Character bands have upper and lower case and some punctuatiion. |

| If the band has a 96 character set at a pitch of 10 Characters Per Inch (CPI) then the character repertoire must be longer than 9.6 inches - probably somewhat longer to leave a clear inter character gap. Given that the hammer-bank width is typically 13.6 inches the character set and printing is at 1200 lines per minute then the band is travelling at about 272 inches per second - or about 7 metres per second. |  |

The band has to keep moving constantly and predictably although it is under a varying load as the hammers hit, so the drive motor is usually powerful and the drive pulleys are quite heavy. The speed of the printer is determined by how fast the hammers can fire and retract, more than by how fast the band travels - the two speeds need to match one another.

Statistical Bands.

One way of speeding up the print process is to use "statistically organised" bands. The character sequence is organised using statistics on character frequency in English, so having more of letter "E" and fewer of "Z" means there is more probability of a required character being under a hammer. This optimises throughput, but the design is more complex - software within the printer needs to track the characters. Bands could also be numeric statistical because "0" and "1" are more common than other digits. With entirely numeric printed data it will make sense to have an entirely numeric band giving much higher print speeds.

Ribbon.

The ribbon is simply caught between print-band and paper when the hammers fire. Ribbons look simple - just fabric soaked in ink. (Ribbon print is sometimes described as towel printing). Ribbons are not as straight-forward and simple as they may seem at first sight - they are actually the "working surface" of the printer. When the hammer hits it carries the band and the ibbon onto the paper. (or sometimes the paper onto the band !)

Ribbons are usually a silky fabric with a fine texture and the ink is held in place by adhesion and capilliary action. The fabric needs to be robust - a close woven polyester is a common choice. Ideally the ink should be solid when static and liquify under impact. The ribbon would then be dry to the touch, and the ink would dry instantly on the paper. In practice most inks are a gel to the touch and the liquid component is absorbed rapidly by the paper leaving dry ink within a few seconds.

Bandprinter ribbons are not usually narrow strips like typewriter ibbons because they would wear out very quickly. Typical ribbons are two inches or more wide and set at an angle to the page. At the right-hand side the print band contacts the bottom of the ribbon, at the left it contacts the top, Wide ribbons like this can have a very long life - 20 million characters or more. Ribbon life is typically half a million to a million lines which could be 10- 20,000 heavily printed pages. Most bandprinters aren't generally used for densely printed pages - more typically they print fewer than 20 lines per page so a ribbon might last as long as hundred thousand pages. Bandprinter ribbons don't act as an oil to the print process so whilst the printing is still clear they can still be used (unlike dot-matrix ibbons).

At least on design of drum printer had page-sized ribbons - the ribbon was the width of a hand-towel and wound vertically. A very wide and long ribbon could learly have an impressive production capability and since it is only ink inpregnated cloth the costs need not be all that high.There are two ways the ribbon can be held:

Spools - the ribbon is gradually wound between a pair of spools, from one to the other. Ribbon was usually multi-pass, winding back and forth several times. The ribbon surface is locally exhausted and dried out where it is used in a print pass, but whilst it is stored on a spool ink from elsewhere runs into the pores and efreshes the surface for another pass.

Older printers often use spools, and they are also sometimes used on more recent machines where high reliability and very low operating cost are the main criteria. Loading the spools into the printer is not a particularly messy job - but don't wear white clothing!

The spool can pack ribbon tightly so there may be several hundred metres of material.

Cartridges - the ribbon is a continual strip held in an oblong plastic cartridge. (its usually a mobius strip so both sides of the fabric get used) There may be a hundred metres or more of ribbon fan-folded into the cartridge. The ribbon usually feeds out of a tension gate on one side, and is pulled tight across the page by a capstan at the other side which also folds the ribbon back into the cartridge. Ribbons often travel in the opposite direction to the print band because this keeps the ribbon under tension.

Cartridges are generally easier to load than spools. Cartridges are also proprietary, so they are more expensive than a simple ribbon spool.

A cartridge usually mounts at an angle to the print band so that the whole surface of the ribbon is used. This can make the cartridge "look wrong" to users. Make sure the cartridge seats properly on its clips and capstan because it is possible for the band to wreck a brand new ribbon- which is rather expensive.

The ribbon shield prevents the ribbon from rubbing against the paper in any position where it is not lined up with the print- band. If the ribbon is allowed to contact the paper more widely minor folds in it's surface cause random streaking. Ribbon shields are just strips or sheets of mylar with a slot cut where the print-band is active. Over a long time friction from paper and ribbon will wear the shield out and it will need replacing.

--

Outline Operation.

For each print position, mechanical operations are as follows. The machines logic determines which character is wanted, and what character is currently going past on the band. When the two are about to match, the hammer is fired; this impacts band, paper, ribbon and platen together. The hammer must immediately retract or the continued travel of the band will smudge the outline of the character. This requirement means that the forward and backward travel of the hammer must be very rapid - much faster than implied by the rate of 20 characters per second for each print position. If the character position takes about 1/20th of a second to print and 2% horizontal bluring of a character is acceptable then the point of impact can't last much longer than 1 millisecond.

Electronic operations are fairly simple. The printer assembles a line of print it has received from the computer into a memory space.

The position of the print band is sensed by an optical or magnetic detector - there is usually a double-mark for the start of the character sequence, then one or two marks for every character. The printer electronics knows the pattern on the band, on recent printer it is in a ROM. The control electronics might have a shift-register to cycle the characters on the band past the character line to be printed held in another register. When the characters match, the hammer fires. If part of the line went "ABCDEF" and those characters were lined up against 6 successive hammers then all six hammers would fire at once. On the other hand if the line reads "******" then successive hammers fire as the asterisk on the band moves past.

When a whole line has been printed the machine can move on to the next line. An efficient printer will already have taken the next line into memory so printing can begin as soon as the paper has been moved.

Older printers often did have some kind of shift register matched against a static register with gates sensing a match and actuating a hammer. The logic boards were quite impressive, though like the hammer bank the logic was repetitive. In more recent devices an ASIC or a moderately powerful general purpose microprocessor can do the job - supervising the collection of print-hammers is just a program loop.

Recent bandprinter designs use one or two microprocessors for control. One handles the time-critical printband matching whilst the other assembles data and maybe controls the motors and sensors.

Moving paper and hammers rapidly does mean delivering brief pulses of high current power to the motors and hammer-bank solenoids, so the printer may well have several circuit-boards covered with impressive looking power-transistors. The power supply unit also needs to be capable of handling massive surge currents when the band is printing an alphabetic sequence and all the hammers fire at once.

For a fast printer the bandprinters electronic inner workings are nevertheless elatively straight-forward.

Paper movement is often just a powerful stepper motor. The paper moves one sixth of an inch (usually) for each line then stops dead wilst the line prints. Some printers use a DC servo with tacho-generator or optical feedback and this may be potentially faster, particularly if the paper is to accelerate over non-print areas.

Printers often have some kind of paper movement tachograph. This can be a rubber wheel turning a small DC motor that acts as a generator - the electronics monitors the voltage to see that the paper is feeding correctly. Other methods are to use a slotted wheel opto encoder or even to monitor the passing of the half-inch tractor feed holes.

The paper feed tacho is a common source of problems in older printers. One issue is that the rubber wheel denatures and slips and the printer logic then sees a paper movement problem even though there isn't one.

Mechanically band-printers are big and quite complex.

| The printer case has to be big to enclose the paper and the hammer bank. The hammer bank is usually on a stout metal frame - it needs to be quite rigidly held and with 136 solenoids it is quite heavy. The size is more a reflection of the need to protect users from the noise of operation than anything else. Setting the hammer timing means working with the covers off and the noise levels range from "obtrusive" to "deafening". With the cover on bandprinters aren't usually very disruptive. Don't expect to hold a quiet conversation across a working machine. The basic paper transport mechanism is like that of any other printer – just bigger and more powerful for faster paper movement. |  |

Larger printers often have motorised forms stackers. A 1200 line per minute printer handling invoice stationery can output 3 or 4 pages per second so if the paper isn’t neatly stacked it quickly gets out of control.

The forms stacker is a motorised table at the rear of the printer that catches fan-fold printer and positions itself so that the paper re-folds neatly. The stacker uses a couple of light-beams across the page to guage where the table should be positioned, and a couple of motors to move it up and down.

Stackers are a sourse of trouble. Paper swarf gets caught in the optical sensors. Paper that has been brushed by a moving ribbon carries surface electric charges and sheets repel one another or attract to the side of the case. There is often a "tinsel" wire to discharge static from the paper.

Bandprinters are fast but given the fact that they can only output characters the data exchange on the computer interface isn't all that massive - just a couple of thousand characters per second. A page of laser print can easily be several megabytes of colour pixel data. A page solidly printed by a bandprinter cant contain more than 60 lines of 136 characters - 8160 in total. A bandprinter is rarely limited by using a "Centronics" or IEEE 1284 parallel interface. An RS232 interface running at 9,600 baud may well be adequate.

Bandprinters do tend to have a special interface. The "Dataproducts" connector is quite common - its a parallel transfer but wholly unlike Centronics (lots more pins). A DEC LP37 can even have a fiber optic interface. Bandprinters often work alongside mainframes, so unusual interfaces have been used.

Inflexible working is the main problem with band-printers – graphical capabilities and fonts are limited to what is on the band. There is a design variant that can overcome this:

The band itself can contain nothing but dots. The characters are then made up using a dot-matrix pattern, rather than by being pressed from a solid form. One obvious limitation is that each dot-position needs a hammer movement.

If the characters are formed on a 9 x 7 matrix then superficially it seems that 63 hammer-firings are needed to form each letter –and this would make the printer much slower than a machine using solid forms.

Actually the average character only has about 17 dots, so the arithmetic isn't quite so bad. This may not be as much of a limitation as it sounds because the mechanical actions needed to fire a dot-hammer can be speeded up considerably if it only comprises a dot. IBM 4234 printers use this kind of mechanism and achieve an interesting balance between speed and graphical capability.

The dot printer's ability to act like a bandprinter but produce reasonable dot-matrix graphics is rather impressive.

Line matrix printers ("also known as shuttle printers") use a hammer bank entirely made of dots arranged across the page. The line matrix printer can produce fonts, graphics and bar-codes so it is far more flexible than a band printer. Unfortunately the shuttle printer suffers from the same maintenance problems as the band-printer. It is heavy and only field adjustable, there are anything from 40 to 136 dot actuators and they all need tuning. Adjustment has to be done by field service engineers working under pressure. Shuttle printers can produce barcodes - but those barcodes may often give ead errors.

Most band-printers are technically obsolete - no longer made. However the extremely low operating cost and reliability of band-printers will probably mean that many are in service for years to come.

There is an alternative line-printer design using a print drum. The drum printer typically had a big metal drum with a circumference of about 8 to 10 inches covered in a matrix of characters. The drum gives each character position a whole set of characters. Operation is fairly similar to a band printer - when the character position coincides with what is wanted then the hammer fires. The problem with drum printers is the huge drum - a third of a metre long with 64 or 96 characters in 132 or 136 columns. This means the drum has up to 13,000 perfectly formed characters in metal - making it both beautiful and expensive.

Environmentally band-printers are quite benign – considering their ability to consume whole forests worth of paper. If a task demands a lot of printing then that paper was going to be used anyway. The ribbons are often quite large and expensive, but they use fairly conventional printing ink embedded in fabric and are not generally thought to be hazardous.

It is possible to get ribbons re-inked (or at least it used to be) with perhaps some decline in quality - but then with a bandprinter high quality print usually takes second place to economical operation. The ink is a fairly conventional printing ink.

Power consumption is not that great - under a kilowatt in full flow which is quite good for a fast printer. Bandprinters don't usually have a low power standby state (fans and things go on running) but there isn't any penalty to simply turning them off. A newly designed bandprinter probably could operate quite economically but most designs date back to the 1980s and energy consumption was less of an issue then.

Almost uniquely amongst modern computer equipment band-printers sometimes contain a substantial amount of metal- so whilst it may not be worth much as scrap the parts have potential for re-cycling. As with all computer equipment the complexity problem applies – many of the components are intricate and dismantling them for efficient metal recovery would take several hours manual work. The value of metal recovered will not pay for the transport and labour of dismantling a machine.