| Laser Printer Fuser Printers > Laser > Fuser | Navigation Icons Guide

|

This is a shortened but still fairly full outline of what a fuser is and what it does. There is a longer version.

The basic mechanism of the laser printer makes an electrostatic image on the photoconductor, which attracts toner powder that is finally transferred to the paper. The toner powder will blow away unless it is fixed to the paper, and this job is done by the fuser.

Fusers can work several different ways but they all tend to use a combination of heat or pressure - most use both. Toner is a soft plastic like styrene mixed with a colourant like carbon black and sometimes forming a microcapsule around wax. A fuser briefly heats the paper and toner to about 150 centigrade as the page rolls between two rollers and the toner then sticks to the page.

Fusers are designed to deal with a particular kind of toner. The temperature can often be adjusted up to deal with heavy media and down to deal with things like transparencies. The speed of the printer can also be adjusted, for instance so that a fuser dealing with transparency might run cooler but slower so the printer gets a chance to anneal the toner into the surface.

The fuser heated roller has to be non-stick to the toner and any media it is likely to encounter so the working surface is generally "teflon". If the fuser becomes sticky any image passing through it will transfer to the rollers and then repeat and fade down the page. Printer manufacturers match the temperature and speed of the fuser to the characteristics of the toner they use in cartridges.

A potential problem with recycled or clone toner cartridges is that they can mismatch the fuser. In the worst cases using a mismatched toner has been known to coat a fuser with molten toner bringing it to a halt. More likely a mismatch means a slow build-up of "cooked" toner on the fuser, shortening its life.

Fuser designs vary. Large fusers with a big working surface can last for several hundred thousand pages. Small fusers where one small surface has to do a lot of work can have a design life as low as 50,000 pages. Exactly how long a fuser will last will depend on the amount of toner used. Low cost colour printers tend to be used for photographs which have a high page cover so the small fuser is likely to have a short life.

Fuser Designs:

Two common designs are used:

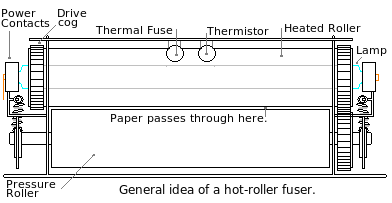

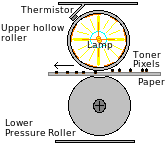

Hot roller designs have a metal heated roller at the top and a rubber pressure roller underneath. The heat source is usually a tungsten halide strip lamp. Paper sheets pass between the rollers which are both turning and the momentary rise in temperature melts the toner sufficiently for it to adhere to the paper.

Hot roller fusers take a minute or more to warm through to the point where they can be used. In older printers they are kept turned on and the surplus heat is blown away by a fan. Quite commonly seven tenths of the printer's power consumption is keeping the fuser in a ready state when it isn't actually printing. Newer printers will reduce the fuser temperature after a few minutes to save power, but that means keeping users waiting when they want pages printing.

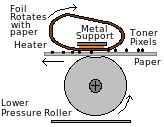

Foil designs replace the heated roller by a cylinder of thin foil of some material. Running on the inside of the foil is a ceramic bar with a heater element. Paper passes between the bottom roller and the heated foil. The foil is free to rotate with the page so that where bottom roller, paper, toner and foil nip together the printing is not smudged. On larger printers the foil may be a longer belt driven by friction rollers or sprocket holes.

Because the ceramic heater element is quite small its temperature can rise rapidly. The foil transfers heat to the toner and paper. The foil temperature is relatively even and the paper and heater aren't directly in contact so the paper doesn't discolour or char. Because the foil is free to move the softened toner doesn't smear.

Foil fusers take 10-20 seconds to warm up for use so they can be turned off when they aren't needed saving electricity. In principle the ceramic heater is a bit more robust than the lamp used in the older design and might last longer. However the foil itself is an obvious point of weakness, it needs to be able to turn thousands of times without wearing through or ripping.

Both designs are in use today. Hot rollers are more common in large, fast machines like photocopiers and colour printers. People don't buy printers this size to then leave them idle for long periods - although if they are left on at night they could well be wasting a lot of power. Foil based fusers were first used in small desktop printers and proved successful, so they have become more common across the size spectrum.

Traditional Fusers:

Teflon Rollers.

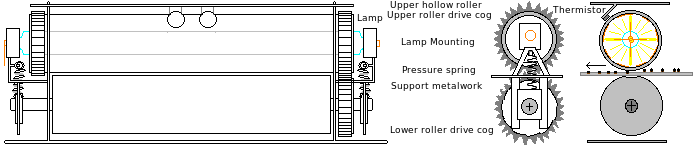

The traditional design for a fuser uses two rollers:

The traditional design for a fuser uses two rollers:

A heated roller at the top. If the hot roller were the lower of the two convection would unevenly heat its partner.

A rubber pinch roller is underneath. The rubber needs to be heat resisting so it is often made of a fairly soft silicone rubber on a metal shaft. The rubber roller is usually brown or orange for some reason.

The heated roller is usually a hollow tube of aluminium mounted in heat resisting plastic bearings and driven round by a gear at one end.

Conventional lubricated ball bearings might prove troublesome, not so much because of the high temperature, which is trivial compared with car engines but because of the environment. There is bound to be a certain amount of paper dust in a printer that will tend to jam bearings. The roller turns in a pair of smooth heat resistant plastic circles set in the fuser metalwork; it takes a bit of effort to push this round by hand but the drive motor can cope with it.

To prevent toner and other material adhering the roller has a polytetrafluoroethylene coat or Dupont "Teflon" as it is usually known.. The Teflon coated roller is heated to about 150 - 200C - the exact temperature depends on the grade of toner used and on the rate at which the paper is expected to pass through the fuser. Fast printers tend to use a hotter fuser but the paper is in contact with the roller for a shorter time.

Teflon coating is necessary or paper dust and toner will congeal on the roller - the temperature is not dissimilar to that of a frying-pan.

Heater.

The fuser is normally heated by a tungsten halide strip lamp mounted inside the metal roller. This kind of lamp is similar to those used in security lights and in some kinds of cooker, but those used in printers have to be as long as the fuser - about 8.5 inches for an A4 model and 11 inches for an A3 printer. When the printer is first turned on this lamp will stay on for some time providing initial heat to the roller wrapped around it. The fuser rollers need to turn so that heat is evenly distributed. The mass of the fuser roller gives some temperature stability when cold sheets of paper are passing through.

The fuser is normally heated by a tungsten halide strip lamp mounted inside the metal roller. This kind of lamp is similar to those used in security lights and in some kinds of cooker, but those used in printers have to be as long as the fuser - about 8.5 inches for an A4 model and 11 inches for an A3 printer. When the printer is first turned on this lamp will stay on for some time providing initial heat to the roller wrapped around it. The fuser rollers need to turn so that heat is evenly distributed. The mass of the fuser roller gives some temperature stability when cold sheets of paper are passing through.After the initial warm-up the lamp will light every ten seconds or so to maintain the temperature. A thermistor on the roller senses the temperature. The fuser temperature is controlled by this thermistor circuit which normally feeds back into the engine controller board which turns the heating lamp on and off.

To make the fuser come to temperature rapidly a more powerful lamp might be paired with thinner metal components. If the fuser can reach temperature very quickly it does not need to stay hot all the time - the processor can allow it to cool down between prints and this will save energy. The obvious problems are that a thin metal roller will lack mechanical integrity and thermal mass so it may cool down unevenly when lots of successive pages pass through and it may not resist wear or hold its shape very well.

The traditional fuser has a roller about 30 to 40 millimetres in diameter made of metal about 1 - 2 millimetres thick. The thickness is sufficient for mechanical integrity and to ensure the stream of cold paper doesn't cool the roller too much.

In effect a big metal tube is being heated by a small filament running at 3,500 centigrade along its centre. The heat passes through the glass wall of the lamp tube, then an air gap to the inside roller wall which acts as a thermal reservoir for the paper at about 150 centigrade. When paper passing through cools the fuser the thermistor circuit turns the lamp on and it rapidly reheats the roller. Perhaps it is surprising that this works as well as it does.

Ricoh multifunction copiers with "QSU" (quick start up) use twin halogen heaters and an ultra thin roller. The twin heaters reduce the heating time and allow the electronics to compensate for the rapid cooling of the thin metal roller. Ricoh also uses low temperature toners so the temperature doesn't have to rise so far.

Canon and HP use a foil and a ceramic heating element. Foils are the ultimate in thin walled rollers, responding almost immediately to heat. A ceramic heater in direct contact with the foil does not need to run as hot as a halogen lamp would so it can be longer lasting.

Temperature Controls.

Temperature monitoring for the heated roller is normally provided by a thermistor mounted about half-way along the fuser chassis. The thermistor is a small bead of ceramic or plastic just a millimetre or so across. It is usually held in a cradle of insulating rock-wool and pressed up against the roller, it is protected from wear by a thin layer of heat-resisting plastic.

The thermistor may act as a simple thermostat via a comparator circuit, usually built into the engine controller or power supply. More sophisticated printers will feed the thermistor to an analogue to digital converter in the engine controller logic circuits and may set different temperature levels depending on whether the printer is in stand-by, what kind of paper is being fed and even on type of toner.

Thermal Fuse

In case the temperature control mechanism fails a thermal fuse is usually provided. The idea of this is that if the heater circuit were to lock on for some reason - like the engine controller processor crashing - it will prevent the fuser mechanism melting and the printer catching fire. The thermal fuse is usually a mechanical cut-out in one of the heater power leads so even if the electronics go berserk the fuser should still fail safe. Both the thermistor and the thermal cut-out are pressed up against the fuser body, and they tend to wear through the Teflon coat. A fairly common cause of fuser failure has been a mark in the coating caused by this wear.

Silcone Oil.

There is naturally some tendency for the heated toner passing through the fuser to adhere to the rollers. Historically this was reduced by coating the rollers in a very thin layer of silicone oil. The coating comes from a cleaning pad usually located in the top of the fuser. A very small amount of oil will serve for several thousand pages of work, but if the pad is not replaced spent toner will begin to build up on the rollers. High-volume and colour printers and photocopiers often have a bottle of fuser-oil which needs to be periodically changed.

There is some evidence that failing to replace the cleaning pad also causes the thermistor and cut-out to wear into the Teflon rather faster than they otherwise would.

Silicone oil has been widely used in photocopiers for many years. The Canon EP-83 / HP 4500 engine was the first to eliminate the oil by incorporating a wax bead within the colour toner. Fast printers still sometimes use silicone oil but it's a messy substance to have in an office environment so micro-encapsulated toners and other formulations that avoid its use are likely to dominate.

Large colour printers where the fuser's non-stick ability is most challenged still often incorporate a web-oiler which applies a thin layer of oil to the fuser as it works. Some Lexmark printers have the option for a web-oiler fuser to be fitted if they deal with a lot of label or vinyl stationery.

Foil Sheet.

Many recent printers do not have a Teflon coated roller, instead they have a sheet of this or some other polymer which rotates around a halogen or ceramic heater. This design is sold by Canon as "on-demand" printing and by HP as "instant-on". It first appeared on some of the smaller HP machines like the "5L" and has been progressively adopted in larger and faster machines. These fusers have small ceramic elements that can turn on and off rapidly. Foil designs have no air-gap between the heater and the material and the foil itself is thin so it almost instantaneously takes on the temperature of the heater.

Many recent printers do not have a Teflon coated roller, instead they have a sheet of this or some other polymer which rotates around a halogen or ceramic heater. This design is sold by Canon as "on-demand" printing and by HP as "instant-on". It first appeared on some of the smaller HP machines like the "5L" and has been progressively adopted in larger and faster machines. These fusers have small ceramic elements that can turn on and off rapidly. Foil designs have no air-gap between the heater and the material and the foil itself is thin so it almost instantaneously takes on the temperature of the heater.

The paper passes into the fuser between a roller and the foil. It is usually the roller that is driven, the foil is free to turn around the ceramic heater, perhaps with the help of a pair of guides to keep it straight and cylindrical.

If the paper were to pass directly in contact with a static ceramic heating element the toner would smear. A heater could be arranged over but not in contact with the paper, but with no pressure on the molten toner it would be difficult to get good adhesion without excessively drying and discolouring the page. The foil gives direct contact and pressure without smearing.

Because the foil sheet fuser can heat up to working temperature in seconds it can be shut down when it isn't needed without the user noticing any start-up delay in printing. This helps save energy and gives the printer a rapid start up.

Another potential advantage of foil is that whilst many are roughly cylindrical they need not be; the foil could be a belt or even a belt with several folds packing a much larger working surface into the space.

Fuser Life.

Fusers have a long life but they do wear out - they are sometimes described as an engineer-changeable consumable. Fuser failure can cause a lot of aggravation because they are an expensive part - the retail price on fusers is often more than £150 and the call-out charge for fitting may be another £50 - £100. Since low-cost printers sell for less than £300 it could be cheaper to get another printer. (If it weren't for the cost of consumables already bought, changing the computer drivers and learning to use a new toy).

A typical manufacturers rating for a fuser built with a halogen-heated teflon-coated roller is 150,000 pages. Practical engineering experience suggests that earlier failure can happen. There are probably several causes:

- One might be the UK use of high kaolin paper. This builds up on the thermal sensors and begins eroding the teflon.

- Another might be failure to replace the silica-oil cleaning pad in the top of the fuser.

- A likely cause of sudden failure is that a foreign object such as a staple has passed through the machine. Engineers quite regularly find small metal objects inside printers and it would not be surprising if the odd one passed right through the fuser and back out.

- A surprisingly frequent cause of damage is users taking a paper-knife to the mechanism to try and free up a paper-jam. Seeing what looks like a metal roller they push hard – and score the teflon coat.

- When a fuser starts giving dirty print well before its expected life there is an issue with the media or the toner in use. Media like labels can leave traces of adhesive. Incorrect toner can bake onto the teflon and build up.

- The halogen lamp in a fuser will ultimately fail, although many last beyond the design-life of the printer. The lamp element will go brittle with age so the point of failure is often after a printer has been moved – often because of engineering work for some other problem.

Printer manufacturers are not very generous with the warranty on fusers, it is normally just 90 days which is simply a standard in the spares industry. What evidence we have from the few fusers that seem to just fail for no readily apparent reason is that HP will sometimes take up cases where a fuser seems to have lasted an unduly short time but that some others will not.

Fuser Repair.

Laser Printer fuser units users can be repaired in principle. The economics of this depend on availability of spares, how much a replacement unit costs and how long it takes a technician to strip and rebuild a fuser. The parts most likely to fail are rollers and lamps and these can often be bought and replaced.

When replacing a roller look at the surface of the sensors and ensure they are clean – if they are not then they will start gouging the surface of the new roller straight away.

In a few cases the bearings of a fuser become damaged. The bearings are often a brittle heat-resistant plastic and are quite likely to snap – if this happens the fuser is a write off unless spares can be taken from another unit.

The bearings also sometimes melt – if this has happened beware of fitting a new fuser because the real fault may be that:

- the triac that controls the halogen lamp has failed open-circuit.

- the sensor that controls the fuser temperature is not making proper electrical contact

- the sensor circuit has drifted well out of specification.

Foil fusers can also be repaired, if you can get the bits. However this is more difficult and with a few exceptions printer manufacturers don't seem to make manufacturers original parts available to do it. The foil is intended to travel in one direction and will be marked in some way - or observe the markings on the old foil if there is enough of it left. As well as the foil itself some lubricant paste is needed. The foil itself is easily damaged and even a fractional tear will quickly spread and result in very premature failure. A little experience of selling foils put us off the idea!

Refurbishment

Refurbished fusers are those repaired on a commercial basis. There are several companies that specialise in refurbishing fusers. To get the old fuser cores they pay a small amount then they do the work of replacing the damaged components.A clear problem with refurbishing a fuser is that it is more labour intensive than merely making one since old fusers must be demolished by unscrewing their parts first and then a series of judgements made about used parts.

Refurbishment done in the UK is obviously expensive because of relatively high labour costs, it also tends to be quite small scale so there often won't be fusers for the more obscure printers because the refurbisher either can't get the cores or can't get the parts.

Refurbishment seems to be moving to large scale operations in low labour cost countries. A larger operation will be better able to balance supply and demand for cores - but it wouldn't be surprising to find it less responsive if there is an issue with the product.

From the outside it may be impossible to know which route is taken, a UK refurbisher may also buy in bulk product. The fuser is then boxed and returned and usually sells for about half to two-thirds the price of a new item.

The kind of problems likely with refurbished printers are similar to those that might happen when fixing a fuser. A specialist refurbishment shop is less likely to make mistakes in fitting a foil but that does rely on the people being trained. A counter-argument is that people in a refurbishment shop will be under time pressure whereas someone fixing their own machine can take care to get it right.

Summary

Fusers are designed for fairly long lives compared to toner cartridges, but they don't usually last forever. Most fusers last between 50,000 and 200,000 pages depending on the design. Little cheap printers tend to have short fuser lives. Fusers used in "workgroup" printers tend to be long lasting and easily replaced.How expensive it is to replace a fuser is a matter very largely decided by the printer manufacturer. Although fusers are made by subcontractors, the printer brand-owner has fairly good control of the replacement part market and effectively decides how easily and quickly replacements will be available. If a manufacturer says the fuser will last "the life of the printer" that usually means the printer is cheap and has a short life and replacements may be hard to get.

Fusers can be designed with longer lives but that tends to make them bigger. Fusers can also use rollers or foils - this is one of several energy saving designs and curiously it doesn't necessarily have an impact on the life of the fuser.

Fuser life can be shortened by using inappropriate media such as the wrong grade of transparency, labels or envelopes for instance. Wrong grades of toner in recycled cartridges can also shorten a fuser's life.

© Graham Huskinson 2010

This page is like all those in the "book" section in being under development.

If you think this page is wrong in some respect or have better information on how things are done let us know. Click here.