| Colour Laser Printers Printers > Laser > Colour | Navigation Icons Guide

|

The toner used in photo-static printing can be any colour. It is perfectly possible to have a mono printer working entirely in blue. Coloured toner is a special order, but many recycling shops could make up a toner to suit. Users with big Oce VarioStream printers with long print-runs and house colour schemes can order CustomTone units in exchangeable developers.

CMYK.

Full colour printing means using three colours, usually the subtractive colours Cyan, Magenta and Yellow. These three colours can be blended in proportion to make others. The blending is not perfect- particularly for producing black - an imperfect blend looks brown. Users tend to produce a lot of black and white material even on a colour printer, and this would use a lot of each colour and give an imperfect result. To improve the economics and colour rendering printers normally have a black cartridge as well as the three colours so the process is often known as CMYK (Cyan, Magenta, Yellow and blacK).

It would be possible to line up four monochrome laser engines to produce colour print but the resulting machine would be an expensive monster and prone to paper-jams. Instead most printers use either:

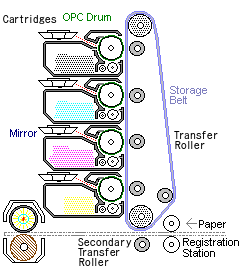

| four toner-developers in a carousel with one OPC belt or drum to create the image and an intermediate store to build up successive images |

| four toner-developers each with an OPCs and a Transfer Belt (ITB or ETB) - an inline print mechanism that will be faster but obviously might be be more expensive. |

| four toner-developer-OPCs and an Electrostatic Transfer Belt transporting the paper and attracting the toner. |

Carousel designs use one OPC so they tend to be cheaper to buy. They could be cheaper to maintain as well since if the colour toners aren't needed for a print job they need not be engaged. The need to switch the carousel around makes them slow when colour print is wanted - typically 4 pages per minute.

Having four OPC drums in a line is more expensive and was first seen in high-end printers but this technique has now moved down to home printer prices. Most recent colour laser printers use inline printing to get higher speed. People may grumble about the price of printing but they grumble much more if the printer takes any time to do the job.

Four Developers & Carousel.

A technique adopted in many early and low cost colour laser printers might be summed up as "carousel". Four toner -developer cartridges are arranged so that they can use one OPC drum. This is generally done by mounting the cartridges in a carousel which turns to face the drum as each colour is processed.The Minolta Page-Pro, HP Color LaserJet 2500, HP CLJ 4500 and HP CLJ 8500 all do this

There is normally a single main OPC belt or drum and this is charged up by a corona wire or transfer roller and scanned by a laser in the same way as any other printer.

The printer makes four passes, each using the same OPC and laser, but with a different developer active.The image from each pass can be transferred straight onto paper, but this would mean:

| shuffling the page back and forwards several times through the transfer station. |

| increasing the transfer voltage to etain the last image whilst aquiring a new one. |

Used like this the machine might not grip the paper so there would be image registration problems - successive colours wouldn't line up. The paper in turn might not grip the image very well, a static charge on paper tends to dissipate across the surface so the image might blur.

An intermediate store takes the image from each colour pass and holds it in place. Minolta, and older HP printers use a belt made of (what looks like) OPC material for the storage belt. QMS and someother printers use a drum coated with rubber - the belt isn't reacting to light, just holding the toner powder using a charge. Once all four images have been built on the intermediate store the paper is moved through the transfer station and a transfer roller pulls the image onto it.

Inline designs

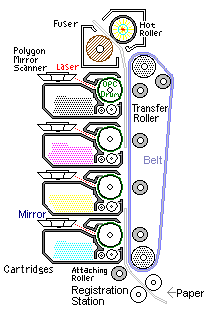

Starting with the HP4600 the print cartridges include toner, developer and the OPC (as well as a waste toner reservoir) These cartridges are arranged one after the other as a production line, or "inline".

The intermediate medium more or less has to be a belt so that it can cross the four print cartridges. However there are two ways this can operate:

One way builds the image on the belt as above but it goes past a succession of four toners with increasing charges. The image built on the belt finally goes past a secondary transfer roller where it is stripped off the belt and onto the paper. This technique is used in the HP Colour Laserjet 3500 and 3700.

One way builds the image on the belt as above but it goes past a succession of four toners with increasing charges. The image built on the belt finally goes past a secondary transfer roller where it is stripped off the belt and onto the paper. This technique is used in the HP Colour Laserjet 3500 and 3700.

The image creating process can be continuous although there might be a brief pause between pages.

Another way to do the job is that the belt grips the paper using it's static field and carries it across the cartridges. The image transfers directly from the OPC to the page, as it would with a mono printer. The belt and paper goes across a series of charge rollers increasing the charge at each point to transfer the successive toners onto the paper. This approach is used in the HP Color LaserJet 4600 and 4700. Since the image is produced in one continuous process rather than shuffled around as it would have to be in a carousel printer it doesn't blur.

Whichever technique is used the belt needs to be able to respond to a succession of static charges from the transfer rollers it crosses. The version that uses the belt as an intermediate stage should probably be called an Intermediate Transfer Belt (ITB). Both kinds of belt are using static to transfer toner so they are Electrostatic Transfer Belts (ETB).

The belt is usually made of OPC type material although it doesn't absolutely have to be. Electrostatic properties of the belt are often used for calibration purposes. The printer prints directly on the belt then moves what it has done past an opto-detector acting as a colorimeter. Then the belt goes past an LED erase station which releases any residual charges. There are all sorts of details like how the belt is cleaned into a waste bottle or into the cartridges that vary greatly among printers.

The belt is usually made of OPC type material although it doesn't absolutely have to be. Electrostatic properties of the belt are often used for calibration purposes. The printer prints directly on the belt then moves what it has done past an opto-detector acting as a colorimeter. Then the belt goes past an LED erase station which releases any residual charges. There are all sorts of details like how the belt is cleaned into a waste bottle or into the cartridges that vary greatly among printers.

The belt is a big item, it has to be as wide as the page and in most current implementations it is long as well so as to pass over a line of four toner - developer - drum units. The belt will ultimately wear out, probably after something more than 100,000 pages. In most of the large printers the belt is a drop in replacement but in a few designs changing it requires various parts to be unscrewed and unplugged.

Another detail is how the printer deals with black only pages. Many printers have a set of mechanical pushrods called anti-aliasing bars which disengage the colour toners when they don't need to be used.

Colour toner is expensive so ideally a printer never engages the colours unless they are going to be used. There is a conflict because when the user does want colour print they don't want to wait whilst the machine calibrates.Colour.

![]() The actual range of colours may not be all that great, if the printer has no greyscale there would be just 8 pixel colours as a esult of mixing cyan, magenta yellow and the white of the page. There is no point in mixing black with anything because the result is still just about black.

The actual range of colours may not be all that great, if the printer has no greyscale there would be just 8 pixel colours as a esult of mixing cyan, magenta yellow and the white of the page. There is no point in mixing black with anything because the result is still just about black.

To make gray the printer would have to apply a trace of black. Laser printers were used to produce neat printed text. To produce a photograph a printer ideally needs a property called grey-scale, the ability to move small amounts of toner in response to a small signal. With original electrophotography process that was difficult to do, toner either moved or it didn't. By using finer toner manufacturers have given printers some grey scale but until recently not the full 256 levels needed to reproduce the 24 bit colour picture from a camera directly.

Fuser.

At this point the only difference between mono and colour printers is the possibly thicker layer of toner and its greater page cover. Colour printing is usually estimated to cover 15-20% of the page compared with around 5% for mono print. If toner sticks to the fuser rollers they will carry it around and deposit it in the wrong place.

It might seem that the fuser on a colour printer does no more work than that on a mono machine, since the page will have much the same character regardless of its content. The greater area of toner on colour pages may tend to exhaust the fuser's teflon coating rather sooner and for this reason the fusers in colour printers are sometimes given shorter life ratings when used to produce colour pages.

Colour laser-printer fusers also tend to be rather more elaborate than their mono counterparts, using larger ollers, a metalised heat transfer band and/or more silica oil for the cleaning process.

Overall Design.

Colour laser printers are usually rather bigger than mono devices because they need to accommodate four toner-developer mechanisms. It is fair to say beware of small colour printers if you want anything beyond the odd colour page. The way to make a small colour printer to make very small cartridges that will innevitably have a high running cost.

Colour laser printers also need extra electronics. The RIP process needs more processor power and memory to deal with the four colour-separated image. One way manufacturers can avoid this is to use USB and rely on the users computer to provide the processing power, but in this case the printer may not be very satisfactory shared on a network.

Colour Printer Prices.

![]() Laser printer manufacturers have made amazing strides in reducing the cost of machines in the last few years. In the mid 1990s colour was unusual, machines were huge and cost £15,000. Around year 2000 the Minolta PagePro was one of the first colour printers that sold for just under £1000; there were few machines selling below £3,000. Now there are many models on the market for less than £500 and special offers sometimes bring the price under £100. Some mono laser printers sell for less than £40 and inkjet models sell for less than £30 in supermarkets.

Laser printer manufacturers have made amazing strides in reducing the cost of machines in the last few years. In the mid 1990s colour was unusual, machines were huge and cost £15,000. Around year 2000 the Minolta PagePro was one of the first colour printers that sold for just under £1000; there were few machines selling below £3,000. Now there are many models on the market for less than £500 and special offers sometimes bring the price under £100. Some mono laser printers sell for less than £40 and inkjet models sell for less than £30 in supermarkets.

Colour laser purchase prices have fallen for several reasons:

| Mass production is clearly a factor. Some products hit a sweet spot where manufacturers see growing demand and aim to take more market share by lowering prices below those of competitors. For colour printers this shift down in prices started to happen around the year 2000 and has probably worked through. |

| Electronics for a colour printer are more complicated. Colour needs four times as much memory as the equivalent mono printer because each colour needs a raster image. The extra memory implies more processing power than a mono printer. The cost of electronics falls with time, however, and the tens of megabytes of RAM needed for colour print is now easily affordable. |

| A colour machine is more complex than a mono printer but stripped down the mechanics need only be a few plastic mouldings and motors together with extra toner cartridges and a belt. Most of the extra parts are cartridges of one sort or another so their initial cost is followed by sales opportunities. |

| High resolution colour laser printers match the needs of producing colour material rather well. Images may not be quite as sharp as those from very high resolution inkjets but colours tend to be more stable and the cost of printing is generally lower. |

| Most printer manufacturers make both inkjet and laser printers so there might not seem a need for laser printers to compete on price with inkjets. In practice the inkjet and laser printer divisions are often different and may be in competition with one another. |

Prices for laser printers can be so low that they compete directly with inkjets. Making a colour inkjet is a matter of incorporating an extra position on the carriage and some extra control paths in the circuitry - so there is not much to it beyond the cost of the cartridge and the manufacturer hopes to make money by selling more of them. The colour laser printer has to incorporate extra mechanisms - a cartridge carousel and an intermediate transfer mechanism. Extra complexity can be paid for by:

Having a bigger market - colour lasers have gone from being something graphics studios might afford into offices and general home use.

Selling more cartridges - colour lasers are an opportunity to get users covering more pages with more toner. Sales catalogues often don't give any indication of price per page on low-cost colour printers.

The price spread on colour printers may surprise some people. At the time of writing the HP LaserJet 2600N is on the market for £179, whilst the Laserjet 4700N has a base price of £960 and £1275 for the network version with duplexer. They are both 600dpi A4 colour printers.

Differences are:

Print speed - 2600n - 8ppm; 4700 - 31ppm

Ccolour cartridge yield - 2600n - 2000 pages; 4700 10,000 pages

Duty cycle - maximum 2600n 35,000 pages; 4700 - 100,000 pages

Electrostatic Belt Life: 4700 120,000 pages

Fuser Life: 4700 150,000 pages

The higher price gets faster print, a higher build quality, and larger, longer lasting cartridges.

Colour Operating Costs.

Page-per-minute and price-per-page ratings for colour laser printers can be quite misleading.

There is nothing inherently expensive about coloured rather than black toner. Colour printers are more complicated than their mono equivalent and need four toners. That doesn't mean the price of inking a page with colour is automatically greater than mono pages; although it usually is. There are several reasons:

- The printer itself is more complicated so it must cost somewhat more (although manufacturers might subsidise the price of printers to get toner sales).

- The belt is an additional cost and although they have lives of the order 100,000 pages they have prices around £100. Likewise the fuser life may be shortened if using colour increases the average page cover.

- Users are very much more likely to include a lot of graphics and particularly photographs in what they print if they have a colour printer.

The four toners in a colour printer suggest that colour printing might cost four times as much and in general that is probably a good guess. The page life of mono cartridges is normally measured at 5% page cover and the test methodology is set out in an international standard (ISO /IEC 19752  ). The IEC has been working on a standard 19798 for colour printers but hasn't yet ratified it.

). The IEC has been working on a standard 19798 for colour printers but hasn't yet ratified it.

Estimates of average colour page cover vary but are of the order 15-20%.

Operating Efficiency.

Colour print tends to be more expensive than the same page in mono - although conceivably it need not be. To give a theoretical example, if you write in magenta there is no self-evident reason why that should cost much more than black (although coloured toners do tend to cost a bit more). If you write in green the printer is mixing yellow and cyan; a laser printer makes the production colour green by overprinting yellow on cyan toner giving solid green. Red, green and blue as production colours are twice the price of single toners.

Price-per-page is only intermittently promoted directly by manufacturers when they think they have something to boast about. One reason is because it is difficult to determine page cost unarguably - but also because marketing people would prefer it to be forgotten.

Operating costs obviously depend on circumstances. If a manufacturer gives a price per page at all it is generally for text on ordinary copier paper and is typically about 3p -7p for a colour laser printer.

- Colour lasers are cheaper to operate than most inkjet printers -

- colour toner seems to be cheaper than coloured ink

- cartridges are bigger so the dealer margin tends to be smaller as a proportion of the cost.

- colour lasers normally produce nice looking material using ordinary copy paper- where inkjets need special paper

Very few people buy a colour printer in order to write letters in green ink, (attractive as the idea may be). Colour printers sell to people who want big, bold colour photographs, boxes, logos and other page furniture. Colour photographs have almost 100% page cover. In fact, since production colours may take two toners a landscape with a green hillside (cyan and yellow) and a blue sky (cyan and magenta) could have nearer 200% page cover.

If you plan to produce 50 copies of a full colour glossy magazine with a printer then try multiplying any manufacturer cited cost by 20 to see what a page could cost. Double that again for those dark, moody shots designers love so much.

Printers work significantly more efficiently if they run continually. When a printer starts up it tends to run the rollers for a few seconds in a "calibration" process where toner that has has been exposed unused is moved to the waste bottle. Getting an even coating of toner on the developer requires the machine to run for a few seconds before it prints. Unfortunately the average print job is about 5 pages long and is followed by a long period of idle time which is not efficient.Experience running catalogs through colour printers suggests they eally do consume a lot of cartridges - although for small runs up to a couple of hundred copies it will still be cheaper than a commercial offset litho print job.

Clones & Refills.

People worried about operating cost often think in terms of buying clone cartridges or getting old cartridges refilled. Refilling ought to be a good idea because toner usually runs out well before the developer is exhausted. There are dozens of cartridge models and refilling works better on some. Usually the larger, older models seem to refill more effectively than the newer devices which are often chipped in an attempt to make it more difficult. However don't expect any cartridge to last forever. Most cartridges are good for one refill, perhaps two, then another manufacturers original will be needed.

The exact colouring of the toner can be very important if a printer is used for photographic information. This has two results:

| Refilling may not work at all well if the printer is to reproduce photographs. The exact colour and properties of the manufacturers originals may not be matched. |

| Clone cartridges may not work very well. again the toners aren't blending with the precision the manufacturer achieved. |

Clone cartridges have become more difficult to obtain after a US court judgement suggested Epson should be paid a license by those copying it's designs.

Low Use Costs.

Costs for very low use of a colour printer may be surprisingly high. Many office printers are used largely for mono text, with some colour where needed. Most models of printer run through a little exercise when they start up and move any toner exposed into the waste bottle. The manufacturers eckon that otherwise dust and oxidation of the toner can spoil photographs on the first page. If the printer is used for a single page now and then this wasting of material can substantially increase operating costs.

A way to gauge whether printers are wasting toner in this way is whether you can hear the carousel going round when the machine starts up - they usually do.

A colour printer is meant to be used.

We used to say that if you want a mono printer, buy a mono printer. Some colour printers now claim that they can run as mono printers without extra expense.

Print Times.

Most manufacturers give page-per minute ratings from 8ppm to 30ppm for colour print. Many printers don't meet the rated speed when faced with eal print jobs. Part of the reason, of course, is that the print jobs wanted are rather more complicated than those the estimates are based on.

Inkjets are notorious for not living up to the manufacturers claims on speed; page preparation relies on the users computer. "Host based" laser printers do this as well. Many laser printers are more intelligent, they interpret a print language that mainly communicates text and vectors, the idea being to take some of the processing burden off the computer. Complicated page layouts require a lot of memory and processing power in the printer and if they are not up to the job the printer slows down.

Colour laser printers are often used to produce short runs of brochures and publicity material. If four copies of a 5 page document are needed it may be much quicker to send each page five times than to send five copies of the document. This way the RIP only needs to make up the page image once, the printer can then reproduce it four times at full speed.

If each page is sent in sequence then the RIP has to make up each page separately 5 time over.

Some printers boast "RIP once" technology which means they don't e-make the page each time. To get this they may need the hard-disk option. Printers with disks in cost quite a lot more than the base model.

Print times can usually be reduced by putting more RAM into a printer - if it can take it. Printers made in the last few years generally have a socket for PC66 / PC100 type DIMM - but check the manual because printers have used 72 pin SIMMs and completely non-standard modules as well.

Do check that the printer driver has seen the extra RAM - particularly on Linux where this may not happen automatically. If the printer driver believes the printer to have a small RAM then it will try to render pictures in the computer's memory, probably taking much longer about it than necessary.

Is Colour Print Worth It?

Some activities demand colour. Satellite photography in colour simply has more information than the same thing in mono - the greens of grass are different to the blues, greys and blacks of water. Anything spatial, maps, engineering diagrams or anatomical information will be more quickly understood in colour.

Not all information is enhanced by colour. Text may be more difficult to understand, for instance. Text on coloured backgrounds and textures may look decorative but is normally less readable.

However colour text is eye catching. Many people are overloaded with information and give a limited amount of time and attention to any source.

There are lots of sources of information today - television, video, adio, magazines, newspaper, bookshops, libraries, advertising hoardings, e-mail, correspondence, phone and personal contact. Researchers have suggested that the average manager gets over 150 messages per day. At this rate the decision time on seemingly minor issues like whether to bin or file a sales brochure is probably about a second - even briefer than the "elevator pitch".

Colour helps communicate if it makes a document more likely to selected and read.

The only reason to put information on paper is to communicate. If colour printing makes people more likely to read and understand a document then it is worth the extra cost.

--© Graham Huskinson 2010

This page is like all those in the "book" section in being under development.

If you think this page is wrong in some respect or have better information on how things are done let us know. Click here.