Colour Print

There are lots of attitudes to the written word and how it should look on the page:

One is that it should be as unobtrusive as possible, the reader is seeing the words but constructing a world in their head. This is what should happen when someone is reading a novel, the actual page has gone, the reader is elsewhere. The page could be perfectly plain.

Another is that a page should be a work of art, something attractive even if it is not immediately read and understood. Things are more likely to be read and understood if they are attractively presented. But if there is too much ornamentation then the meaning of the text is lost in the artwork.

Printing has always struggled to be both highly readable and attractive. Handmade books can combine print and painting as medieval manuscripts do but they took a lifetime to produce and ownership was the privilege of aristocracy. Literacy might now be normal, but some people are still suspicious that books carry pretensions.

Printing and Expectation

Typewriters were invented in 1868 but the idea took another 20 years to become very popular.

For a long time computer printers struggled to reproduce what can be done with a typewriter. Through to the 1970s computer printers were uppercase only, fixed fonts, no proportional spacing and rather smudgy black print. Pages were readable, all the information was there, but the appearance was awful.

In the 1990s inkjet and then laser printers began to be capable of producing coloured work looking as good as a colour magazine - or even a medieval manuscript. The remaining problems are how to produce pages with an impact, the cost of printing, and when to use plain text.

The limit on printing today is human imagination and perhaps budget. There are industrial inkjets that will print on any surface - even those with a texture several millimetres deep.

In fact the issue with colour is not whether you want it - with inkjet printers you don't have much choice, there isn't a black-only option.

Colour

Light is an electromagnetic vibration travelling through space. In free space it moves rapidly, at almost 300,000 kilometers per second. In materials like glass it slows slightly, so that a convex lens delays rays at its centre more than those at the edge, which refract toward a focus .

The vibrations of light are physically small in human terms, at wavelengths from about 300 nanometers to 780 nanometers (a nanometer is a millionth of a millimeter). Animals have eyes which sense the vibrations and some animals have sensors with slightly differing structures which means they can sense colour. Red light is a wavelength around 740nm and blue around 380nm. Humans can't sense frequencies outside that range but many insects can see in the ultra-violet at 300nm.

Sight is useful to us for remote sensing, most animals have it. Colour is useful because a lot of chemicals reflect and some react at the wavelengths we see as light. We can make judgements such as the health of a fruit or flower by its colour. Mono aerial photographs are quite difficult to read, rivers, fields, factories and houses have different textures but that is all. Colour aerial photos like Google Earth

burst into life.

Colour Psychology

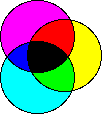

The CMYK Process

The subtractive colour processes used in printing were invented in the 19th century. Printing starts with a white page that reflects light. Adding black ink subtracts all the colours from the reflection and gives the maximum contrast so that is best for text.

Cyan ink subtracts all the red, leaving the blue-green components to be reflected

Magenta subtracts all the green, leaving the red-blue components reflected

Yellow subtracts all the blue, leaving the red-green components reflected

Overprinting yellow and magenta takes away green and blue so the only light reflected is red.

The RGB process used with screens is additive, red, green and blue subpixels are turned on to give white light. This wouldn't work well with print because overprinting red with blue in the hopes of getting magenta wouldn't work - there should be no blue light coming through the red. With an RGB printing process the result of any overprint should be black. (Mixing red and blue paint gives purple but overpaining does not![]() .)

.)

Most print processes either apply ink or not, they can't dilute the ink as we might with paint or make the coat thinner to achieve a lighter shade. Printers developed a technique called half-toning to make lighter shades. Half tone divides the image into small dots and increases the area of the dot to increase the intensity of the colour. To make the whitish blue of a northern sky the machine prints a lot of cyan dots and perhaps a bit of magenta but leaves areas of the page white.

Computer Print

There have always been ways to achieve colour computer print, using a pen-plotter for instance. Colour copiers appeared in the 1980s, they were big and expensive (budgeting £ 20,000 would be about right) and there were a few colour laser printers built on the same lines.

There are four common print technologies at present: dot matrix, thermal, laser and inkjet. Each can be made black only or colour.

Dot Matrix

Dot matrix printers use printhead pins to strike ink out of a ribbon and onto the page. A technique invented for typewriters used a ribbon with a top half red and a bottom half black. A little mechanism called a ribbon lift shifted the colour. Dot matrix printers sometimes used the same technique with a four colour ribbon to print colour. The printhead would move across the platen four times producing a line in each successive colour. If all that is wanted is a small area of colour to stress that money is owing or something like that then the technique works. Producing a photograph in colour takes a dot matrix printer a great deal of time and the results are murky at best.

Thermal Transfer

Thermal transfer printers can produce colour using two or three methods. With a mono transfer the foil is just one long strip of thin plastic with the transfer wax one continual colour. To make a colour printer the thermal foil can hold four successive blocks of colour matching the page size. As the foil winds over the page it produces magenta, then the mechanism pulls the page (or the head) back to its starting point and produces cyan and so forth. The cost of foil is quadrupled but for some kinds of work like photo printing the effort might be worth it. Fargo made A4 printers like this in the mid 1990s. Now the technique is mainly used for identity cards.

Roland and Alps have both made colour thermal printers which have an array of colour thermal foils a print line wide inside their lids. The print carriage positions itself next to the required ribbon, picks it up and puts it in the print position and prints a line or so. Then to change colour the machine returns the ribbon, selects another and on we go. The process is slow but the printers do produce rather nice output. They also have an unusual ability to handle gold and silver foils - there aren't many printers that can achieve actual metallic gold. Unfortunately Alps now seems to sell its machines only in Japan.

Given that thermal printheads occupy very little space and don't cost much to manufacture a third possibility would be to have four successive mechanisms. We aren't aware of any machine that does that.

Laser Colour

Laser printers have two main ways to produce colour which we might call the carousel and inline techniques.

Carousels were favoured at first, they use fewer parts which might make them cheaper to implement. The printer has four toner and developer mechanisms and arranges them next to a single drum. The Canon /HP approach mounts the toner and developer cartridges in a carousel next to single OPC drum which in turn is over a belt. To make the image the printer positions the carousel and the ordinary print process runs making an image which transfers from the drum onto the belt. Then the carousel moves to the next colour and the process runs again and so on until all four colours have been built on the belt. Finally the belt transfers the image onto the page. Mechanisms like this were used in the HP CLJ 4500 and CLJ 8500 and the CLJ 2500. They are still in use in the CLJ 2820 and CLJ 2840.

This technique has an interesting ability to work at quadruple speed for black. If a mono page is all that is wanted the printer just selects black and can get on with its work at four times the colour speed. Hence the printers typically produce colour at just four pages per minute but black at 16 pages per minute. Where colour is only occasionally needed the technique is interesting and potentially quite economical. However if all jobs will be colour it will be slow and use up drums.

Samsung and Lexmark have their own variants on this technique, for instance arranging four toner developers on one side of a drum or using an OPC belt running across developers to make the image.

Inline technique is simpler, it just has four complete toner / developer / drum mechanisms positioned over a belt. They all generate an image on the belt using a succession of transfer voltages. with four complete image susbsystems the printer might be more expensive to make but it can produce colour at the full rated speed.

There are variants in the technique again. For instance the HP CLJ 2600, 3600 and 4600 all transport the paper on the an electronic transfer belt. The CLJ 3500 transfers the image onto the belt and then uses a secondary transfer roller to transfer the image off the belt and onto the page.

Inkjets

Inkjet printers need four print mechanisms to produce colour print as well. Where inkjets differ from other print methods is the ease of adding another colour mechanism. There isn't much problem providing this becuse it is just a matter of having extra cartridge positions (2 for a tricolour printer, four with separate cartridges). After the first set of inks shipped with the printer are used those extra cartridges are a nice little earner for the printer maker, the user buys those.

A colour inkjet printer does need extra space in the carriage for the larger cartridges and it might need more contacts for the increased number of nozzles. But that doesn't actually cost much.

Colour Costs

Whether a printer has colour abilities is a simple objective fact. The implications for ownership costs are less so.

Plain black or "monochrome" print is cheapest; it only uses one pigment and that is carbon black which is inherently cheap. There are even standards about what suppliers can say. Mono printer consumables and parts are sold with a page yield measured at 5% page cover according to ISO/IEC 19752. ![]()

A little spot colour on a document can have a big impact on the reader, a discrete logo and some thin lines can make something look much more professional. But lets face it that isn't how people tend to use colour. Colour documents use photos, logos, backgrounds and solid block cover so page cover isn't 5% or even 20% but often 30%+. A full colour photo of a mudbank or a ploughed field may have nearly 300% cover. (Making brown uses magenta, cyan and yellow). Colour documents use a lot more ink and selling ink has become the core mission for printer vendors.

It's not just ink and toner that gets used. Printing on a colour laser printer will set a transfer belt in motion, on some printers one mono page counts as two belt actions because starting the belt at all imposes wear. Fuser life is also shorter if you print in colour. Manufacturers naturally prefer those costs to be ignored.

Manufacturers have even been known to suggest that their printer will handle "colour at no extra cost". That might be possible but needs challenging

When a laser printer starts up it is probably going to perform its colour calibration, using some toner even though you won't actually print in colour today. Inkjet printers have to uncap the colour heads so they will clean them as well. There are all sorts of hidden angles to what printers do.

What the printer makers probably mean is that it costs the same if you are printing the same sort of pages but (say) putting a colour logo and print where black was used previously; the coloured ink or toner need not be more expensive (although it often is), And they prefer to ignore longer term costs - replacement transfer belts, fusers and general maintenance costs.

It is certainly true that a colour printer can disengage its colour cartridges when they aren't in use. That means that if you never print colour very little colour toner is used. The printer probably will calibrate the colour every time it is powered on, so there is some use, just not much.

The colour printer mechanism is inherently more complicated. Not only are there four print processes instead of one but the way colour print is done there is usually an electrostatic transfer belt that has a limited life which is also being used up printing mono pages. Manufacturers like to suggest the transfer belt and fuser last the life of the printer

whatever that means. There are a few designs which disengage both the colour toners and the belt.

There is a cost to the mechanical complexity of colour printers as well. When the print process goes wrong they are more difficult to fix. It's difficult to put a price on that, of course. A lot of printers scarcely every go wrong in any way that needs more attention than changing the cartridges.

Colour capability is a simple objective fact but the economics of it aren't so simple and promises such as "colour at no extra cost" might be treated with scepticism, at least in today's market.

Colour is a problem but only because manufacturers make it so by setting the cost of ink. Cheap printers and expensive ink is the way the business model has gone so far - it isn't strictly necessary.

Kodak and Kyocera both do aim to compete on running costs. For the most part manufacturers only compete seriously on running costs when it comes to big production oriented machines like the HP CP6015.

Printers intended for the work process like orders and invoices and can do without colour and if you take the temptation away then there can't be any cost. However design, marketing and most home users can't really be expected to do without colour. ![]()