Printer Faults - Horizontal Jitter

Horizontal positioning inaccuracies are usually due to a problem in the laser scanner mechanism. The laser scanner is almost always a motor rotating a multifaceted polygon mirror. Jitter is "noise" in the rotation of the mirror. To cut the story short the most likely problem is a bearing failure and the cure is to replace the scanner assembly, sometimes called a printhead.

There is a problem: the price manufacturers want for a new laser printhead.

People are quite familiar with laser scanners - the bar code reader in most supermarket checkouts incorporates one. The cover is usually semi-transparent and you can just about see the laser pointing at a spinning mirrored disk. Laser printer scanners are similar but use a more powerful laser intended to create a photoelectric reaction in a second over a considerable area. The scanning action is faster as well.

Scanning a Beam.

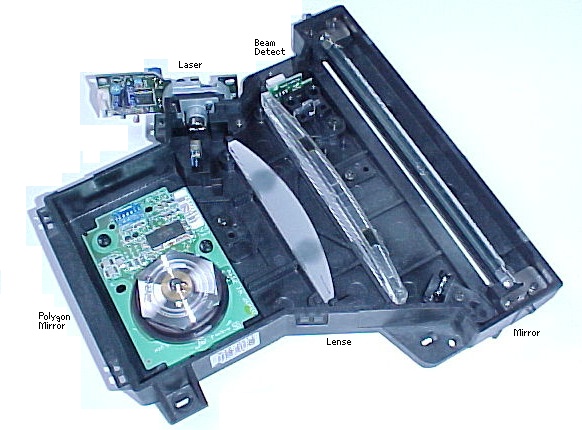

There are several possible ways to scan a laser beam:![]()

In principle the laser diode itself could move but since they are physically a couple of millimetres across whatever was doing the mechanical scanning would fight momentum and probably be slow. All practical techniques mount a mirror on the moving device and then point the laser at it.

A laboratory technique is to use galvanic mirrors. The laser points at a mirror mounted on the shaft of a moving coil meter. This can give very precise steering but it usually isn't fast enough for raster scanning. It isn't a hopeless technique since the moving coils in loudspeakers can achieve frequencies of 10 kilohertz and more - but loudspeaker cones don't move very much.

Mirrors mounted on a piezoelectric crystal or on a micro-mirror device are another possibility. Quartz crystals can oscillate at up to 40MHz but the displacement is tiny.

Polygon mirrors are almost always the answer. A four to eight sided mirror is mounted on the axle of a motor. The general idea is the same as a disco glitter ball which sweeps the beam from a spotlight around a room. In the polygon mirror the motor spins very much faster.

Rapid Spin

Laser printer scanners turn quickly, much more rapidly than most other motors. A laser printed page of A4 at 300 dpi contains 3,300 lines. If it were to print in a second with a 6 sided mirror the motor would have to turn 550 times in one second. To put that in perspective the motor has to rotate at 33,000 rpm, racing car engines sometimes get to a third of that. The polygon mirror scanner is small, lightweight but has to turn very rapidly. With a 1200 dpi printer the polygon mirror has to turn four times as fast again.

Laser printer scanners turn quickly, much more rapidly than most other motors. A laser printed page of A4 at 300 dpi contains 3,300 lines. If it were to print in a second with a 6 sided mirror the motor would have to turn 550 times in one second. To put that in perspective the motor has to rotate at 33,000 rpm, racing car engines sometimes get to a third of that. The polygon mirror scanner is small, lightweight but has to turn very rapidly. With a 1200 dpi printer the polygon mirror has to turn four times as fast again.

With more mirror facets the motor can turn more slowly but the angle of beam displacement falls so that with an 18 facet mirror the mirror angle is 10 degrees and beam deflection 20 degrees. With a many sided mirror the laser would have to focus on the page from some distance away and the mirror optics would need to be very precise because one sweep of the page has to resolve to nearly 10,000 pixels (8.25x1200=9,900 pixels).

The bearings used in laser printer scanners are dynamic fluid types. The bearing has a herringbone pattern lasered into the metalwork of the bearings and in use the metal surfaces do not touch. An alternative is an air bearing.

Scanner Faults

Some years ago laser scanners were a frequent cause of problems.

When the bearings start to fail rotation is slightly uneven and reflected in slight horizontal displacements in print position. Quite often the jitter is worse to one side of the page because the scanning mirror emits a brief pulse into a beam detector at each sweep for synchronisation then loses position toward the far margin.

Onset tends to be quite sudden, perhaps after the printer has been moved. The immediate cause is probably a failing bearing. The long term cause might be things like prolonged use overheating the lubricant and bearings. The cure is to change the laser-scanner assembly, unfortunately they tend to be expensive. Components like new polygon mirror assemblies aren't usually available; they would be difficult to align because the device is operating in the infra-red, contains a moving mirror and is dangerous to eyesight.

Happily laser scanners are less of a problem than they once were. Small objects that rotate thousands of times per second seem to have become routine.

Laser assemblies can also be a cause of slightly faded print. Lasers lose power with age but before worrying about that check the lenses and mirrors. Quite often there is a certain amount of haze and some dust on the optics. Be careful removing the dirt, the mirrored surfaces are metalised on the outside to maximise their reflectivity. Use an optical grade cloth - or at least a soft material with no abrasive dirt. Isopropyl alcohol is probably the best solvent if one is needed.

Copyright G Huskinson & MindMachine Associates Ltd 2012