Printer Faults - Continual Paper Error

If a paper feed error cannot be cleared, this may imply that a paper sensor is obstructed. This can happen because a bit of paper swarf or dust has made its way into the sensor - in which case it will blow or brush out - or perhaps tweezers will help.

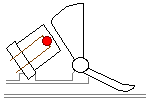

Sometimes a permanent paper feed problems happens when people have cleared a paper jam and accidentally dislodged one of the paper sense flags. This can be a painful fault; the arms protrude into the paper path from circuit boards above or below the accessible parts of the printer. Replacing a dislodged paper sensor can mean dismantling the printer. It can be a simple fault with a costly repair.

When paper jams for the 5th time in 2 minutes as you are printing that urgent report try to keep your temper and not rip the jammed sheet out of there. The printer won't work at all once a paper flag is unseated. If you have got to this page that remark may be too late.

Paper Sensors

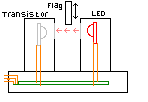

Printers often have several sensors to detect paper passing. These are usually little opto-mechanical devices with a pivot arm which sticks into the paper path and a flag on the other side. When the arm is pushed aside by a sheet of paper the flag breaks a light-beam across an opto-detector nearby. Opto detectors are little U shaped assemblies with an LED on one side and a photo-transistor on the other; they act as highly reliable switches. Mechanical leaf switches have been used instead of opto-detectors on low cost printers but they wear out after thousands of pages. In principle an opto detector never wears out.

Printers often have several sensors to detect paper passing. These are usually little opto-mechanical devices with a pivot arm which sticks into the paper path and a flag on the other side. When the arm is pushed aside by a sheet of paper the flag breaks a light-beam across an opto-detector nearby. Opto detectors are little U shaped assemblies with an LED on one side and a photo-transistor on the other; they act as highly reliable switches. Mechanical leaf switches have been used instead of opto-detectors on low cost printers but they wear out after thousands of pages. In principle an opto detector never wears out.

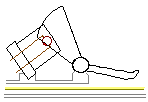

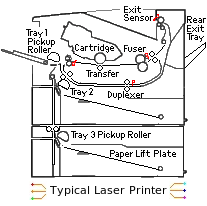

Small laser printers typically have just a couple of sensors, one just after the tray but before the registration station and one just after the fuser. The printer needs to know that paper has actually arrived in the registration station otherwise it would be in danger of printing on the transfer roller - which is to be avoided because it will spoil subsequnt prints by making the rear of the paper dirty (and it's an inconvenient cleaning job).

Small laser printers typically have just a couple of sensors, one just after the tray but before the registration station and one just after the fuser. The printer needs to know that paper has actually arrived in the registration station otherwise it would be in danger of printing on the transfer roller - which is to be avoided because it will spoil subsequnt prints by making the rear of the paper dirty (and it's an inconvenient cleaning job).

Jams are most likely to be before registration, the pickup and feed rollers failed to provide paper or it didn't arrive at the sensor in time.

Jams are most likely to be before registration, the pickup and feed rollers failed to provide paper or it didn't arrive at the sensor in time.

Jams also happen before or during fusing so if the paper makes it out of the fuser the chances are that it will make it out of the printer. Hence fuser exit is the second favourite place for a sensor

Many printers have exit sensors monitoring the level of paper in the face-down tray on top of the machine.

Many printers have exit sensors monitoring the level of paper in the face-down tray on top of the machine.

Larger printers tend to have many more sensors, perhaps ten or more. There can be sensors for paper width - these are often reflective devices. There can also be sensors for paper type - these might be cameras examining the texture.

One of the benfits of working on larger printers is that they often have a service mode which will display the status of the sensors so a problem with one of them is easier to spot. As well as obstruction due to dust and dislodging of the flag a few opto-detectors simply fail after a while from "natural causes". This is difficult to spot - basically the engineer has to trace the circuit to a place where it can be monitored with a meter. Having the printer service software actually display the fault is a better option.

The existence of a service mode and details of the features within it are usually buried in the service manual somewhere.

Copyright G Huskinson & MindMachine Associates Ltd 2012