Printer Faults - Paper Jam in Fuser

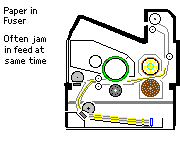

![]() The fuser is one of the parts of a laser printer most likely to fail without giving any explicit message. Usually it is the hot roller or foil which has a problem. This may show first as a paper feed problem.

The fuser is one of the parts of a laser printer most likely to fail without giving any explicit message. Usually it is the hot roller or foil which has a problem. This may show first as a paper feed problem.

The roller or foil have a limited life. Towards the end of their life they will tend to make marks on the page especially at the edges. A foil may entirely degenerate but as there is (usually) no sensor for this it is only likely to be detected when a paper jam occurs.

On the other hand paper jams in the fuser do not necessarily mean the fuser is at fault. It could be the paper pickup or duplexer that has actually caused the fault and a previously printed page is in the fuser at that time. To get the maximum print speed a printer will typically be feeding a new page into the print station the moment another has left and is on its way through the fuser. So note what the printer's control panel says is the problem - i.e. if it's a Laserjet giving a 13.xx error the precise number in " xx". The jammed page does need taking out of the fuser - chances are it will be singed so it can't be used but hopefully since it never emerged the print job will repeat it.

On the other hand paper jams in the fuser do not necessarily mean the fuser is at fault. It could be the paper pickup or duplexer that has actually caused the fault and a previously printed page is in the fuser at that time. To get the maximum print speed a printer will typically be feeding a new page into the print station the moment another has left and is on its way through the fuser. So note what the printer's control panel says is the problem - i.e. if it's a Laserjet giving a 13.xx error the precise number in " xx". The jammed page does need taking out of the fuser - chances are it will be singed so it can't be used but hopefully since it never emerged the print job will repeat it.

Fuser Purpose

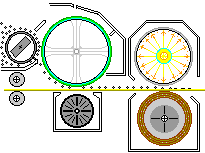

In the print station a laser printer makes a latent image in light on a photoconductive drum. The drum turns and is exposed to a developer carrying toner powder. Turning further the transfer roller pulls the toner powder off the drum and onto the paper.

In the print station a laser printer makes a latent image in light on a photoconductive drum. The drum turns and is exposed to a developer carrying toner powder. Turning further the transfer roller pulls the toner powder off the drum and onto the paper.

In a colour laser printer there are usually four such print stations and an electrostatic transfer belt. Either way the picture is made in loose toner on the page.

Laser printer fusers use a combination of heat and pressure to adhere toner powder to the page. Pressure is applied by carrying the paper between a pair of rollers. Heat is applied by making one of the rollers hot (usually but not always the uppermost).

Fuser Faults

There are two main points of failure in the fuser itself; the heater and the non-stick coat.

Heater

The heater operates usually at below 200 centigrade but to do this it may be:

- an incandescent strip lamp (halogen lamp) actually running at a couple of thousand centigrade and heating the roller by radiation. The heater will ultimately fail as all lamps do.

- a metalised or carbon strip on a ceramic bar. This could be more reliable but it is used in "instant on" fusers so it heats and cools very rapidly and that might create more stress.

Either way the printer can detect heater failure several ways. The heater draws a hefty current and the printer may be able to monitor this. Even if the printer doesn't have current monitoring circuits the heat is controlled by a thermistor and the printer uses it as a thermostat to shut down the heater when it has reached working temeperature. If the heater never does get to working temperature LaserJets give 50.1 or 50.2 errors. Heater faults won't cause paper jams because if the heater can't work properly the printer will go to the relevant error.

Non-Stick

In most laser printers the hot roller is just that- an aluminium roller with a coat of non-stick material such as "Teflon" (or at least a halogenated hydrocarbon). The need for a non-stick material is to stop the toner sticking to the fuser. The problem with non-stick materials is that they aren't very inclined to stick to the roller. After several thousand pages the non-stick material starts to lose its properties. Sometime after that the material begins to rip away from the roller. The result is it normally blots on pages but it is also possible for the paper simply to stick to a roller

Canon and HP use a thin film or foil of non-stick material in their "instant on" fusers. The foil has much less thermal capacity than a hot roller so it comes to working temperature in seconds, where a fuser roller can take a couple of minutes. The film is usually a coating of non-stick material on a plastic or metallised backing. Film based fusers tend to fail just like rollers; the surprise is that such a different material can have very much the same lifespan.

Printer software can make an estimate of how good the non-stick properties are likely to be based on how many pages with what percent cover have been printed. There isn't usually a sensor to detect a failure of the coating - it would need something like a camera strip do the job reliably and in the hot environs of the fuser that might not be practical.

Mechanical Failure

Actual detection of a problem in the fuser is that paper is not reaching the fuser exit paper sensor in time. the problem might be that the fuser is not engaging its drive chain properly.

As already mentioned fusers use pressure. If a page becomes jammed in the fuser then the user needs to be able to remove it, but it is being gripped between the rollers. Printers make various provisions for releasing the rollers - sometimes using blue or green release levers which the users may forget to open or close and sometimes using automatic linkages.

In some cases (notably the LaserJet 4200/4300 series) it is possible to put the fuser in place but not push it home properly and it fails to engage the drive cog. Furthermore the drive cog has a linkage called the swing plate assembly that withdraws from the fuser when the cartridge door is open - the cog on the end of this is notorious for stripping its teeth. With the LaserJet 4200 / 4300 if the machine reports a paper jam but the paper never actually got into the fuser suspect the fuser isn't home properly or the swing plate assembly has finally stripped its gear.(4200 swing plate).

Paper Quality and Paper Path problems.

The path to the fuser normally directs paper between the hot and cold rollers. Because paper might carry an electrostatic charge from the transfer station it sometimes crashes into the front of the fuser and becomes crumpled - this is particularly likely when the paper weight is less than the manufacturer's specification. More annoying routes for lightweight paper to travel are round the drum and round the fuser rollers.

If this happens frequently with ordinary office paper there may be a problem with whatever measures the printer has to discharge static from the page after the transfer station. Sometimes there is a row of metal tips to discharge static (looking like the tear off strip on a box of tinfoil). If the static discharge is not working properly the paper might head in the wrong direction.

In some recent fusers the rollers carry a charge which helps both to keep the toner in its correct place on the paper as it approaches the fuser and the paper from deflecting and creating a jam.

Fuser Exit Sensor

The sensor on a fuser is often close to the hot roller. This is not an ideal place for an optical sensor so it would be no great surprise if they were prone to failure. Some recent printers have a service mode and might be able to report the sensor moving - although it's not in a very convenient place, so a cotton bud or strip of paper might be needed to prod it.

Copyright G Huskinson & MindMachine Associates Ltd 2012