Printer Faults, Stop Test

A stop test is a way to diagnose faults in a laser printer. The idea is to wait until an action that has been causing difficulties is under way and then stop the printer. This causes a paper jam but conveniently the page and cartridge will carry traces of what was under way at the moment the machine stopped. The same idea is sometimes called a "half-page test"or "halfway test".

Obviously the test tends to create a paper jam that has to be cleared - so if you don't feel up to tracing the various places where paper has got stuck DON'T try a stop test. Make sure you are familiar with your printer's various paper paths - they can range from trivial on small machines to elaborate on some large printer / copiers.

Will It Harm the Machine?

Printers aren't built with stop-tests in mind. Printer designers do have to bear in mind that the power might go off in the middle of a print job, so it has to be possible for the user to take the jammed pages out of the machine, for the rollers to clean themselves up and life to continue. To our knowledge there aren't any machines where you must not try a stop test. It's a common engineering procedure.

Interlock Stops the Machine.

The easiest way to stop the printer is usually just to open the cartridge door. Printers have safety interlock switches so this should bring the printer to a halt. The engine stops turning, the laser goes off, and the high voltages are shut down. If the printer doesn't stop - don't go further. The voltages and laser are dangerous and printers should stop when a cover is opened - has someone been fiddling with the interlock switch?(*)

Note that the printer is still physically powered up just as it would be when you clear any other paper jam. You can turn the power off if you feel uneasy, and should turn the power off if you decide the machine needs cleaning up.

Simplify the Paper Path.

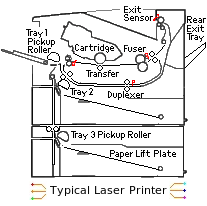

The aim is to identify the source of a fault - feed rollers, registration station, print station and fuser. In normal use there is no way for the user to see when paper is passing these points, or what the page looks like as various parts of the print process are under way, the stop test lets us see what is happening at various points in the process.

Feeding paper from the fold-down multi-purpose tray on the front a a printer sometimes helps with a stop test. You can see how far the paper has progressed into the printer by how much still sticks out. Try to keep the paper path simple and definite.

If the printer is intended to be taking paper from tray-4 or somewhere obscure like that, remove paper from other trays. There are faults that isolate to a particular tray. But normally aim to keep the test simple, use the MP tray or tray 1.

To simplify the print path further; most printers have a face-down paper tray on top but many also have a rear face-up paper tray. Use the face-up tray so you can see the print immediately as it is emerging from the fuser.

Gauging the Right Time.

You have to gauge where the paper is in the print process by sound, or by the time it must take. That is why familiarity with the paper path helps. Sometimes it's just a matter of trial and error. Fast printers are more difficult to work on because they give you under a second to respond.

OPC or Fuser?

Marks on the page in a mono printer are a typical problem the stop-test solves. Wait until a page seems to be just going through the fuser and stop the printer. Take the cartridge out so you can see the print path. The rear cover will need to be opened to see the fuser.

Now examine the paper before and after the fuser

Before the fuser the toner is in loose powder but the page should be perfectly formed. If the marks are present here they are coming from the print process itself.

If the marks do seem to be coming from the print process is it the OPC drum (in the cartridge) or the transfer roller?

Print Cartridge.

Normally we would suggest handling the cartridge as little a possible. Ideally they get installed in the printer and then forgotten about until another is needed. However if you are trying to diagnose a fault there is no alternative but to handle the cartridge.

Turn the cartridge over (carefully- it's full of loose toner) and open the OPC drum shutter. About half of the OPC is normally visible at the bottom of a cartridge. (In some Brother and Lexmark cartridges it is buried inside the cartridge so it can't be seen). Because the print process was stopped in mid flow about a quarter of the drum carries print in loose toner that was destined for the page - are the marks present here as well. If so the problem is deep in the cartridge. With half a dozen stop tests then all the drum surface should have been seen.

In a colour printer look at the belt and in the cartridge shutters, which will have closed when you opened the machine. There will be a bit of unprinted toner visible on the OPC drum - is the visible part correct? With a colour photo a lot of toner is involved and that could be a nuisance getting on hands and around the printer innards - print a light grid instead. Clean hands, clothes and anything else that gets toner on it by using light brushing or cold water - there is more on cleaninghere.

If the problem lies in the OPC or deeper in the cartridge the normal answer is to replace the whole thing.

If a cartridge has been turned over toner will be distributed oddly in it. Hold it level the right way up and shake it a bit from side to side to re-level the toner. (Toners can leak so do this over a sink or a cleanable floor, not over a deep-pile carpet.)

Fuser.

If the fault is coming from the fuser it will only appear there. Stop the page as it is passing through the fuser. If it is a fuser fault the page going in will look good (albeit that the toner is loose) and at the other side it will show the defect. The innards of fusers aren't usually very accessible because users need to be dissuaded from sticking their fingers on a roller heated to 150°C+ - touching a hot roller will hurt. However it is usually possible to see into the fuser to some extent.

If the fault really does seem to come from the fuser then it may be worth taking the fuser out to examine it properly.

Some printers have fusers that are really easy to remove. For instance the HP LaserJet 4200 / 4300 just need the rear door taking off (it unclips) and then the fuser is held by a couple of clips

On the other hand the LJ 1320, P2015, M2727 and Color LaserJet 2600 have fusers located deep inside the mechanism and the covers and many other components need to be removed. Some technical knowledge is needed to do this.

Other problems.

A repetitive image defect fault-ruler is another way to discover what is wrong with a laser printer or copier. Most laser-printer service manuals give a fault-ruler. Most of the processes in a lase printer are carried out by rollers and each has a diameter. If the OPC drum has a circumference of 10cm (and nothing else does) then a fault that repeats at exactly that interval is likely to be the drum. There is more on fault-rulershere.

A stop test can be used to identify things like skewed paper feed, as well. Stop the printer more or less as soon as the paper fed and look to see if it is skewed in the registration station.

A stop-test isn't the answer to everything of course. For instance you probably won't be able to catch paper feed faults early in the process or those later on in the exit assembly.

Stop tests can be used with colour printers although interpreting what is happening is a bit more difficult. There are usually four print cartridges and a transfer belt to examine.

The main problem with a stop test is that you have to carefully clear the printer out after performing one. Don't be impatient and drag pages out of the fuser, release the paper grips if there are levers and pull the pages carefully. Check all through the paper path and remove any paper fragments before restarting the printer.

One of the side benefits of a stop-test is that you have to look carefully at the printer's various components. Is the paper path clean? Are the cartridge electrical contacts clean? Many of the problems with printers can be solved by just carefully examining the parts.

Copyright G Huskinson & MindMachine Associates Ltd 2012