Printer Technology

The first thing a printer technician wants to know about a printer is what technology it uses, assuming they don't know from the name or guess from the look of the thing. Technology has made a big difference in the past, setting the speed, reliability, expected costs of ownership and repairability of things. This bundle of ideas might be called the "value proposition" by marketing people.

There are a lot of digital print technologies. Drum printers were common until the 1980s and band printers are still in use. Teleprinters were often used as output devices, so were IBM Selectric typewriters. Diablo 630 daisy wheel printers produced good looking print. The HP laserjet had Diablo 630 emulation. Then there were photo-typesetters that held character images on film or on disk and exposed the film one character at a time. These machines were all curious by today's standards because they use a fixed glyph for their typeface. There were laser printers that actually burned an image direct onto the paper, they were fast but expensive. Graphics were produced by pen plotters - machines that physically pulled a drawing pen around. To give an idea of costs a band printer might cost $20,000 and a daisywheel typewriter or A3 pen plotter $2,000. All of these machines were specialist devices with fairly small markets and they are rare items now. The pen plotter does have descendants - vinyl cutters and engraving machines.

Digital printers have many features in common. Almost all recent printers make pictures out of dots. A great many dots are needed to make a page. An A4 page printed at 300 dots per inch potentially contains about 8 million of them for instance.

The dots are little points of material in one or more colours. Information on a screen is just points of light. Print on a page is a transfer of material. The paper medium and the dye or pigment get used up. The dots might remain or merge, either way a person viewing them at some distance perceives an image, text or a picture.![]()

To produce millions of dots on a page and trillions over a lifetime digital print mechanisms need to be robust - or easily replaceable.

Printer users perhaps shouldn't need to know about print technologies. In practice it make a difference.

| | Dot Matrix Printers |  |  | |

The first mass market printers were dot matrix machines. Dot matrix dates back to 1970. As its name suggests the printer makes rows and columns of dots on the page. This is done by hitting a ribbon with a solenoid driven pin. Using just one pin to scan out a page would be a bit slow so normally 9 or more are arranged in a column intended to produce one line of western style text. The pins and the solenoids that drive them are usually arranged in a printhead which is then scanned back and forth across the page in a carriage making a line of text or graphics at each pass.

There is a technical limit on how fast the pins can move at about 3,000 times per second. At 10 characters per inch and 10 positions per character across a 14 inch page a line can be printed in around half a second. That's about the upper limit of what can be achieved with one printhead. Some printers have two or even four heads. There are also parallel dot matrix machines that print a whole pagewidth of dots, but clearly they are more complicated and expensive.

Dot matrix printing could be cheap in principle because nothing gets used except an inked ribbon. At one time OKI ML-82 printers used standard typewriter ribbons which were commonplace and could easily be re-inked so they were really cheap to run. The printheads do wear out and they can be very expensive although they need not be (at one time pins were user changeable). A hint here is that printheads may wear more if you don't change the ribbon often enough because the pins use ink as a lubricant.

The price of dot matrix printers started in the $2,000 league expected for specialist machinery. With the growth in the PC market this fell to the $500 level where they could be bought by small offices and hobbyists. By 1990 basic machines were selling for under $100. To get a bigger market share manufacturers aimed to produce higher quality print so they started using 24 pin printheads and high quality cartridge loading ribbons. Since the dot matrix was doomed to be surpassed by inkjet printers that might have been a mistake. Today dot matrix printers seem to have become specialist items again although their ability to print multipart documents and to work in difficult conditions will probably give them a lasting market.

| | Thermal Printers |  |  |  | |

Thermal printers appeared in cash registers and fax machines in the 1970s. The printhead is nothing more than a bar of smooth ceramic with little resistive heaters embedded in it so that there are 150 or more per inch - the more heaters the better the resolution. There are thermal printers with resolutions of 600dpi capable of producing an excellent picture. Thermal printers can work in two or three different ways.

Direct thermal printing uses paper with a special coating. The coat is usually of something called "leuco dye" mixed with or possibly encapsulated in wax to ensure heat transfer. The leuco dye changes colour permanently when it is heated. Thermal fax paper used to be expensive but has been so widely used that costs isn't usually an issue. For barcode labelling and suchlike tasks the printer manufacturers might choose to use odd label sizes or odd ways of signalling the inter-label gap. They have a bit of a tendency to try to control the market and then the price of special stationery can be rather high. Thermal material is not expensive in itself; special forms of it can be.

Thermal transfer uses plain paper but print comes from a foil of very thin plastic coated with a thin but opaque layer of wax. Each patch of foil can be used only once but it is very thin so several hundred metres fit on a small roll and need not be very expensive. Transferred onto paper the wax gives quite a hard long lasting material so it is used for labels that must survive a few years. Using four sets of foil the printer can produce colour photos and product labels.

Thermal transfer is not intended to be cheap; it aims to do jobs cost effectively and with unrivalled simplicity. Typical uses are warehouse labelling where the speed at which the printer can work and the ease of loading and using labels often make it the best choice. It is also used for jobs like monogramming anything from leather to wallets. Thermal transfer material can be printed with an inkjet and then ironed onto fabric.

Thermal printers allow some extraordinary machines like the wallet sized Brother mPrint shown on the right. It can communicate with a PDA by bluetooth so salesmen, engineers, police and traffic wardens can print a computer record wherever they are working.

| | Laser Printers |  |  |  | |

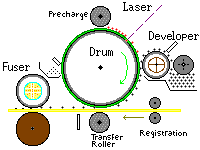

The heart of a laser printer is a semiconductor material. This is usually a metal drum the width of a page coated with a plastic called OPC. Organic Photo Conductor (OPC) is an insulator in the dark but conductive in light. Around the drum are organised three or four other rollers. One roller pre-charges the photoconductor drum with a high voltage.

The drum rotates and is scanned with the image. The image is normally created using a laser, it's a small infrared device pointed at a rotating mirror to give the scanning action. Where the light hits the drum it loses its charge, now there is a latent image in static charge on its surface.

Rotating further the drum comes next to the developer, a roller carrying a coat of toner powder. Toner powder is made from fine particles of plastic and they are attracted to areas of the drum that carry a charge so as it moves past the developer the drum becomes coated with the image that will print.

Next the drum moves over the paper which is being driven past it by the registration roller. Under the paper is the transfer roller. The transfer roller carries a charge that will pull the toner powder away from the drum and onto the paper so the image is pulled across.

The image is now on the page but in dry toner powder. The drum goes on rotating past a cleaning station, most drums are about 2-3 inches in circumference so they turn 3 or 4 times to produce a page.

The toner needs sticking to the page and this job is done by the fuser. Fusers normally use two rollers and a combination of heat and pressure to do the job. The toner part-melts in the fuser to the point where it sticks to the paper.

The printed page is ejected from the printer and the parts all return to position ready for the next page.

Laser printers first became commercially popular in 1984. Canon's "LPB-8" engine was used by Apple to make a high performance desktop publishing machine that cost $6995 and by HP to make a replacement for office typewriters at a cost around $2995. Both machines had a speed of up to 8 pages per minute and a resolution of 300dpi. The cost difference is explained by the "formatter", the computer built into the printer.

Apple's LaserWriter could support full page graphics and the PostScript language; to do this it needed a 1.5 megabyte memory - huge for the time. Apple more or less invented desk-top publishing and established a reputation for design brilliance.

HP's LaserJet had just 128kb of memory and the PCL language used for dot-matrix printers but it could produce word-processed documents better than any typewriter. HP sold millions of machines and established "LaserJet" as the brand name for office printers.

With a big market established competitors entered the market in large numbers. At one time the Canon engine appeared as something like 150 different models of printer.

Technological progress has been increases in

- -speed typically up to 60 pages per minute (beyond this sheet fed paper gives difficulties)

- -resolution usually to 1200dpi (which needs finer toner, more memory and more processing power)

- -memory so the amount a typical printer ships with ranges from 2MB to 128MB on mono machines (P4515) and 512MB with a maximum of a gigabyte on colour devices (CM3530)

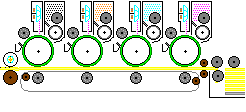

The other big advance has been the introduction of colour

Colour laser printers typically use four sets of imaging elements, each with a different coloured toner (the CMYKprocess). This makes a rather complicated mechanism but since the demand is huge mass production (and the economics of cartridges) delivers affordable products.

The commercial progress has been impressive.

Offices now depend on laser printers and that has created a big market of about 20 million laser printers per year in various forms.

Recent laser printers range in price from about $60 for a little 20 page per minute desktop machine to over $2,000 for an A3 colour machine. Prices can be a lot higher for big office models with multiple trays and finishing options because these add to the complexity and sell in smaller numbers. The Espresso book machine can print a book on demand however with the collating, binding and trimming the machine currently costs fractionally under $100,000. In 2010 Blackwells has one in a London store and plans for roll-out to 60 stores in the UK.

Laser printers have complicated mechanisms but they can largely be modularised as cartridges. The HP / Canon design uses one print cartridge for the toner and the main imaging rollers in a mono machine. Other than the laser scanner and the HT power supplies the whole imaging subsystem is a cartridge. That means most faults can be identified by swapping the cartridge - and that's cheaper than the call-out charge for a technician. A colour machine has four imaging subsystems, each in it's own cartridge. Having four cartridges does make life a bit more difficult but a rule of thumb is that if only one colour has a fault its the cartridge and if all four have a fault its the transfer belt.

There are about 20 manufacturers involved making laser printers so the market looks highly competitive. For low priced machines most of the manufacturers seem to use the same "razor blade" sales model of selling printers cheaply but cartridges expensively. Presumably the manufacturers have demand curve models and figure that by halving the price of cartridges they wouldn't triple sales. More expensive printers print at a lower cost per page![]() .

.

Inkjet Printers |  |  |  |  | |

The market for laser printers is large but that for inkjets is larger. The potential for inkjets starts with individuals printing a photo from a mobile phone and goes all the way up to billboards. ![]() Inkjets are competing with analog screen and offset litho printing in industries like packaging. Inkjets could substantially take over from other forms of print in the next few years.

Inkjets are competing with analog screen and offset litho printing in industries like packaging. Inkjets could substantially take over from other forms of print in the next few years.

Inkjets are the only way to produce a really good looking photo because they can use light coloured inks and picolitre droplets to give a wide colour gamut. Inkjets are the best way to make a printer for wide paper because all it really needs is longer carriage rails and trailing cable. If you want a home printer then all the technical sophistication can be placed in the printhead and that can be so cheap as to be disposable. Inkjets have an image problem, IT technicians regard them as trouble. One little bit of dust and it makes streaky print. The problem for inkjet designers is to make something that really is reliable in "field" conditions - or to make changing heads and ink cheap.

The idea of inkjet printing has an immediate appeal. Take a bottle of ink and force it through a nozzle. A fine stream will break up into small droplets. If the drops could be placed accurately onto the page we would have a way to print using very little beyond cheap liquid ink and paper - non of those lithographic plates, noisy printheads or churning rollers. After some 40 years of effort it seems that dream may be coming true.

Thermal Inkjets

Thermal inkjets use the beautifully simple but non-obvious idea of momentarily boiling ink to make droplets. Early printheads had two essential parts, a metal "orifice plate" containing nozzles and a set of electrical resistors just under the nozzles. The gap between the resistors and the nozzles fills with ink from a reservoir.

To fire a droplet from a nozzle the resistor is fed a pulse of electric current. The resistor turns the electric power to heat. The little resistor gets hot enough to momentarily vaporise the liquid ink. The displacement and acoustic shockwave ejects a bubble of ink from the nearby nozzle. Power goes off, the vapour bubble condenses and collapses and liquid ink cools the resistor ready for the next shot. With some physics regarding surface tension, nozzle and resistor size and pulse duration the ink bubbles form nice small dots on a piece of paper.

The real beauty of the thermal inkjet head is it's cost. Electrical resistors can be nothing more than thinned sections of metallic material, tantalum aluminium is used for heat and acid resistance. Nozzles can be reliably electroformed in metal plates for pence. There are problems such as aligning the components of the printhead. The genius in a thermal printhead, at least in its basic form, is that it can be disposable. The printhead is built onto a plastic tank of ink and if it gets irremediably clogged or if one of the resistors fails the thing justgets binned. That solves the reliability problem.

HP's Thinkjet and Canon's Bubblejet BJ-80 both had just 12 nozzles and were intended to compete with dot matrix printers. They looked like dot matrix printers and had tractor feed for paper handling, although they really needed special paper to absorb the ink. The printheads scanned back and forth in a carriage just as a dot matrix printer would do.

Epson also developed a new inkjet printer but they were taking a different route. The SQ-2000 had 24 small nozzles using piezoelectric ejectors built into a glass printhead with an ink tank in the base. With the right paper it could produce print that looked as though it came from a daisy-wheel typewriter or a laser printer.

The early inkjet printers were only moderately successful but then HP and Canon developed a second generation product.

Technological Development

Despite the development of Inkjets, dot matrix printers dominated the market until the early 1990s. However they began to hit technological and economic limits. Dot matrix could not progress further without new materials or techniques and non were in sight - or have developed since.

Thermal inkjet printheads and their support electronics can be built onto a semiconductor chip. Massive resources are devoted to semiconductor production for processors and memory. Thermal inkjets can benefit from advances in chipmaking. Thermal inkjets could quickly be miniaturised so that a 12 nozzle device shooting about 100 picolitres at the paper could be miniaturized to a several hundred nozzles shooting 1 or 2 picolitres and therefore giving resolutions of the order 2400dpi by 2005.

The HP DeskJet introduced in 1988 increased the nozzle count to 50 and the resolution to 300 dots per inch. This resolution and a good dark ink allowed the claim laser quality for under $1000

(actually $995). DeskJet printers became a best seller. A couple of years later the deskjet 500 with the HP26 black ink improved things a bit further and got the speed up to 3ppm and price down to $729.

Canon's path with the inkjet was different but similarly successful. For the BJ-10v Canon aimed at portability, making a printer that had the same form factor as a notebook computer. This meant sacrificing a few features like automatic paper feed and the ink pump but produced a machine that could be folded up and put in a briefcase alongside a notebook computer.

Colour computer screens are taken for granted now but were quite rare in 1990. Graphical operating systems like Microsoft Windows became increasingly popular and so did colour screens. Digital cameras came onto the market in 1993. It is possible to add colour mechanisms to thermal printers but they tend to be expensive. The dot matrix method using a colour-lift and striped ribbons is not expensive but the results aren't very good. A colour laser printer really needs four almost complete imaging mechanisms which creates an expensive machine.

A colour inkjet also requires four imaging mechanisms but in this case they are just a printhead and an ink tank. Furthermore thermal heads are consumable so the customers pay for replacements. Extra heads add to the complexity of the machine but less than might be thought. A printhead with 100 nozzles would need at least 101 connectors if the printhead chip were a dumb device. Instead of that designers incorporate some decoding logic on the printhead - an address matrix for instance. The only complexity is four heads in the carriage but if they are lightweight that isn't much problem.

HP's PaintJet was not very successful in 1988 but the Deskjet 500C introduced in 1991 was much more successful. The Canon BJC-600 used four ink tanks, the head assembly was removable but not usually intended to be replaced.

Epson had persisted with piezoelectric printheads and produced machines like the SQ-1170 and SQ-2500 which were mono, looked like dot matrix printers and had 48 nozzles. They shifted design with the Stylus 800 - mono and only 48 nozzles but now designed around an A4 cut sheet tray. The big change was the introduction of a new production technique using multi-layer micro-piezo heads.

Epson's Stylus Color (MJ-700V2C) launched in 1994 used the new Micro Piezo heads but had a 64 nozzle black head, 3 x 16 nozzles for colour and a then world beating 720 dpi output. Epson took advantage of the piezo heads to produce a level of half-toning with the heads, something thermal printheads could not easily do.

Because the piezo heads did not need to be disposable the printer could boast better economy than HPs approach. Epson was able to boast

"Our super high resolution is so close to photography", "Environmentally friendly long-lasting permanent head" and "Lower than competitor running costs"

Epson, Canon, HP and Lexmark (who also entered the inkjet market in 1994) were now in a specification race. Rather than try to beat laser printers on speed or cost the main thrust of development was to deliver printers with good looking photographic performance. The main thrust of the inkjet market has been on photographic qualities - resolution, fade resistance, and look of the final product in terms of glossiness.

Aiming at photo-performance helped create a new market for the printer makers - special photo papers. Inks tend to be water based and the dampness needs to be absorbed quickly or colours will bleed excessively.

For about 20 years four competitors have fought for market share, 3 using thermal inkjet and one using piezo technology. Performance and reputation has swung between them. Products have taken a variety of shapes. The latest trend is to put bigger LCD screens on printers so that they can double as digital picture frames and well as multifunction fax copiers.

Specification Race

Inkjet manufacturers have been in competition for twenty years for a rapidly growing market. There are several problems with inkjets:

- - ideally manufacturers want a steady revenue from cartridges that satisfy user expectations on price and life.

- - disposable cartridges integrated with small printheads tend to give slow print and high running costs but an easy answer to problems, change the cartridge

- - get speeds up implying big heads with lots of nozzles

- - improve photo quality which suggests very fine nozzles

- - avoid nozzles blocking - the more there are and the finer they are the more probability one will block

Recent photo printers claim resolutions up to 2400dpi which is a dot size of 100th of a millimetre on a side. Some printers claim resolutions to 9600 dpi, but that is generally an "enhanced" or perceived resolution using different dot sizes. Inkjet manufacturers had a journey to get there.

The inkjet principle with resistors under an orifice plate sounds simple. To make heads with more and finer nozzles manufacturers turned to chipmaking techniques building a control circuit, nozzles and heaters (or piezoelectric actuators) onto a semiconductor chip. Mass produced chips need not be expensive (as singing Christmas cards prove) so there still are disposable heads.

Large inkjet heads for fast print are rather expensive to make, they tend to be designed to be installed independently of the inks and to last for typically four changes of ink cartridge.

Inkjet head manufacture is sufficiently difficult that the only recent mass-market entrant to the market has been Kodak, and they could throw the resources of a fortune 500 company at the job.

There are half a dozen different markets for inkjet printers. As well as the familiar home printing market there is a fairly distinct office-print niche and another for professional photo-printing where A3 would be valued. There are display signage, decorative and textile, graphic arts, packaging and manufacturing / deposition markets. These are all inkjet printers, but fairly distinct in terms of design objectives.

![]() Consumer market inkjet printers aim to deliver a printer with photo capabilities for a low purchase price. Buyers will tend to be impressed by page-per minute claims, but might not realize that the apparent speed is for a low-quality draft. People often seem to forget about the cost of ink - and if they won't do much printing it may not really be an issue. the same is true for paper, if you only print a few pages buying special paper isn't an issue. Reliability doesn't seem to be high on the agenda. Printers using tricolour ink are chaepest to buy but slow and a bit wasteful with ink. Printers with seperate cartridges cost a bit more to buy, but should cost less to run.

Consumer market inkjet printers aim to deliver a printer with photo capabilities for a low purchase price. Buyers will tend to be impressed by page-per minute claims, but might not realize that the apparent speed is for a low-quality draft. People often seem to forget about the cost of ink - and if they won't do much printing it may not really be an issue. the same is true for paper, if you only print a few pages buying special paper isn't an issue. Reliability doesn't seem to be high on the agenda. Printers using tricolour ink are chaepest to buy but slow and a bit wasteful with ink. Printers with seperate cartridges cost a bit more to buy, but should cost less to run.

![]() Large format printers are used for several things. Photographers want A3 or larger and perhaps as many as 10 inks to get

Large format printers are used for several things. Photographers want A3 or larger and perhaps as many as 10 inks to get colour gamut

. There is some overlap with high-end consumer products because there are a lot of keen photographers. The market for computer aided design is fairly distinct, it wants wide format, at least a 24 inch carriage (aka 600mm or "A1" ) and 4 colour inks. These printers are not cheap to buy although they might have large cartridges aimed at cutting running costs. Buyers are very interested in the problem of reliability and manufacturers have provided it by using ink in sealed bags with pressurised cartridges, exchangeable head cleaning assemblies and droplet detectors to discover the status of nozzles. Some of these techniques will work through into consumer printers.

![]() Industrial printers like those made by Inca use multiple heads to print on very wide media and even media with an uneven surface. One Inca printer has been adapted to print on door- panels. As with any industrial machine running costs are an essential part of the calculation on its deployment. There are many different kinds of industrial inkjet with purposes ranging from mass-mailing to painting a bus.

Industrial printers like those made by Inca use multiple heads to print on very wide media and even media with an uneven surface. One Inca printer has been adapted to print on door- panels. As with any industrial machine running costs are an essential part of the calculation on its deployment. There are many different kinds of industrial inkjet with purposes ranging from mass-mailing to painting a bus. ![]()

![]() The office market wants the flexibility and photo quality of inkjet printers but is annoyed by the cost and wastefulness of disposable printheads and won't want to buy special paper for everyday printing. Reliability is an issue as well, the erratic performance of inkjets disrupts office routines. Office printers tend to have separate heads, larger ink tanks and some of the printhead recovery techniques used on large format machines. Manufacturers are frequently claiming - "print for half the cost of laser printing" but the comparrison is with personal lasers - not with proper office laser printers.

The office market wants the flexibility and photo quality of inkjet printers but is annoyed by the cost and wastefulness of disposable printheads and won't want to buy special paper for everyday printing. Reliability is an issue as well, the erratic performance of inkjets disrupts office routines. Office printers tend to have separate heads, larger ink tanks and some of the printhead recovery techniques used on large format machines. Manufacturers are frequently claiming - "print for half the cost of laser printing" but the comparrison is with personal lasers - not with proper office laser printers.

Products like the HP Edgeline CM8060, Ricoh Gelsprinter and Silverbrook Research "MemJet"![]() promise a revolution in office printing - they could genuinely undercut laser printers.

promise a revolution in office printing - they could genuinely undercut laser printers.

Inkjet V Laser

People probably ought to choose a printer based on the look of the output, total costs of ownership (TCO), reliability, speed, colour capabilities, resolution, and special features. In practice they tend to ask "inkjet or laser" first and only then look at the features. It can actually be difficult to penetrate to the real TCO - a manufacturer can change prices overnight. Reliability is guesswork and manufacturers can be devious about speed and resolution. Knowing whether it's an inkjet or a laser is a handy surrogate.

Inkjet technology is very flexible. Inkjet printers with a disposable tricolor cartridge can deliver a consumer-oriented copier / printer that sells in supermarkets for less than £30. For the last twenty years or so inkjets have tended to appeal to home users who don't print much and wouldn't be prepared to pay the higher purchase price of a laser printer.

There is a gradation up through office inkjet models to machines like the HP Designjet 4500. This is a wide bodied printer which can take paper rolls up to 42 inches wide, uses 8 printheads fed by cartridges up to 750ml in size and costs somewhere around £15,000 together with its scanner. Then there's the Color MFP CM8060 with its 60 page per minute rating based on a pagewidth printhead with more than 10,000 nozzles.

Inkjets can achieve things that a laser printer can't - colour print at qualities equalling or exceeding the best photographic prints for instance. Printers like the Canon Pixma Pro series are primarily aimed at professional photographers but the price is low enough to tempt passionate amateurs.

Getting manufacturing scale economies by pitching a product at just the right point to tempt a mixture of customers is something the printer industry is learning.

There has been an idea that inkjets are inferior to laser printer but that clearly isn't so There is much more variability in inkjet than laser printers. Inkjet printers as a generality don't have the lasting qualities of laser printers - hence there sometimes aren't replacement paper pickup roller kits. But there is progress in inkjet design.

Consistent performance is what laser printers do well. There are mono laser printers that have been in daily use for years with just a new (or refurb) cartridge every 18,000 pages and a maintenance kit at 200,000 pages. We have customers who have exceeded 1.5 million pages using a Laserjet 4300.

Laser printers used to be cheaper to run than inkjets and generally still are. A new breed of office inkjet promises lower costs than laser printing, however as suggested above the comparison in adverts aren't always very stright forward. Points not considered in advertising copy are reliability and availability of spares. Most manufacturers make spares available for laser printers - for the smaller inkjets there is often little or nothing available.

Laser printers used to be faster than inkjets. Inkjets had to scan the page, whilst the laser printer rollers processes the whole page in one pass. Printers like the HP Edgeline and MemJet have pagewidth heads so they can process a page in one pass giving them speeds of 60 pages per minute. Whether the costs can be brought below those of laser printers remains to be seen.

Reading technical papers and staff memoirs it's clear that since inkjets were discovered in the early 1980s both Canon and HP managements have tended to favour inkjet research and been somewhat surprised to find laser printer development advancing as well. The balance may even have swung a bit towards the ‘laser’ printer because the cost of a fast formatter with a lot of memory has become insignificant and other developments like LED light sources improve reliability. The demise of the laser printer has been predicted many times and still hasn't happened.

Copyright G Huskinson & MindMachine Associates Ltd 2012