Continuous Stationery

Continuous Stationery or "tractor feed" forms are a continual length of paper with holes punched at regular intervals down the margins. In use the holes mesh with pins or "sprockets" on a forms tractor to get reliable paper feed through a machine. It is the equivalent of the web-feed mechanism used on large presses, but the sprocket holes give precise control of position. The paper is normally "fanfolded", bent alternate ways into box. It is also usually serated at the folds, a line of partial cuts is punched across as it is being formed.

Continual forms were standard practice in computer printing until the 1990s but are now only common on a few machines like dot-matrix printers.

There are laser printers that take continual forms, but they are not common and are usually intended for work like public utilities billing.

- Once paper is loaded with Top-Of-Form set the printer normally needs very little attention and can often work its way through 2,000 pages of print without supervision.

- Printing costs for dot matrix and line-printers can be very low.

- Paper can be converted to more normal shapes automatically using forms stackers, bursters, decollators and guillotines.

There are several problems with continuous stationery:

- Paper quality often isn't very good. The average continual forms paper is lightweight, partly because a typical use has lways been to make multi-part copies.

- Paper sizes are somewhat non-standard. There is a 9.5 inch by 11 inch version which is roughly US-letter sized when the tractor-feed holes have been removed. The 15 inch by 11 inch size is not entirely unlike A3. However offices used to have to buy special ring binders and filing cabinets to accommodate computer stationery

- Sometimes the output doesn't stack neatly. Usually that is because the paper is in a draught, or too close to a wall (static deflection). Printers intended for high volume use sometimes have a forms stacker to ensure paper does fold neatly.

- Machines using this kind of paper handling are no longer standard office gear.

- People are no longer used to handling forms tractors, setting the platen gap and tearing sheets off.

From the 1990s onwards it has become common for computer printers to use pre-cut sheets in the standard ISO-216 or North American paper sizes normally used in offices.

Machines have a problem picking up one piece of paper, as do people. However with textured and slightly damp finger tips and the many freedoms of movement in our fingers people manage to pick up a piece of paper. It can be sensible to have a person load the paper and then just have a couple of thousand pages follow on, which is what roll and fanfold paper allows.

The best machine pickup mechanism is to use vacuum cups to lift a sheet of paper. Printing presses equipped for pre-cut sheet often do this however ordinary office printers never do, the vacuum pump would be too noisy.

The traditional solution to getting realiable paper feed from an office machine is to use continuous feed, preferably with forms tractors.

When it is manufactured paper is normally taken up onto rolls. Printing machines that take rolls of paper are often called web-fed - the web itself being the flow of material from a paper making machine.

Newspapers and print works often take paper in the roll form as it comes from the paper mill. These rolls are big, typically 54 inch wide and about a meter in diameter, the only way they can be handled is with a fork-lift. Paper is made more convenient by cutting and folding and movement is most reliable

To overcome problems moving paper the computer industry imposed it's own standard for many years - the tractor feed paper used by drum, band and dot matrix printers. Continuous form paper is supplied in one long piece, usually 2000 sheets to a box. The size of a box is probably a matter of convenient weight.

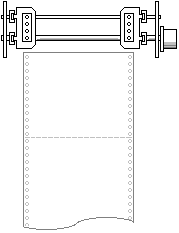

Rather than being on a roll it is fan-folded into the shape of ordinary sheets. There are usually slit perforations along the folds to make it easy to separate into sheets. The paper has holes at half inch intervals on either side which engage with pins on the feed rollers or tractors. Paper is held by sprocket feed holes so that it has no freedom of movement. Printers designed for this paper have forms tractors

to move the paper.

Paper like this was used in tabulating machines in the 1920s and the first UNIVAC had a 130 column printer using this kind of stationery.

The 15 inch paper is good for some purposes - for instance printing out spreadsheets. However for many purposes it simply too wide, a line of print more than 80 characters long is difficult to read. To help keep the eyes on the right line in text alternate lines often have a green shading. Green may have been chosen because it doesn't show much in green light, so a computer printed document can be photocopied and the green lines largely dissapear.

Wide paper is valuable for spreadsheets and diagrams but annoying for text. People might have appreciated it more arranged in two columns, or as two pages.

Ordinary office workers never really liked tractor feed paper, it didn't fit with century-old office practices.

A great many arrangements of holes are possible. At one time different manufacturers had their own hole spacing and size.

Pull Tractors are above the print position and pull the paper through it. Gravity gives some tension to the paper in the print station.

Push Tractors are under the print position

Copyright G Huskinson & MindMachine Associates Ltd 2012