Color Laserjet 2600 Series Cartridge Operation

The HP Color LaserJet 2600 series are small colour laser printers first made in 2005 and withdrawn from manufacture in 2008. They were designed to be low cost, not much more expensive than a professional inkjet printer but with the reliability and running costs of a laser printer. They proved very popular, greatly boosting the interest in colour laser print. Members of the CLJ 2600 series are the Color LaserJet 1600, 2600N, 2605 and the CM1015 and CM1017 multifunction print, scan and copy machines.

The CLJ 2600 series all take the same cartridges, the Q6000A black, Q6001A cyan, Q6002A yellow and Q6003A magenta. The colour cartridges carry a charge of toner sufficient for 2000 pages of print. The black cartridge is physically no different but rated for 2500 pages. (colour density or just a fuller toner hopper?)

Evaluation of the CLJ 2600

Printers are no longer made to this design, subsequent small printers used and intermediate belt and secondary transfer station. In 2012 this series are still widely used. There have been improvements in printer design since these were made but it is mainly in the quantity of memory available and the resolution enhancement algorithm. Newer machines might perform better when asked to print large photos.

Windows 7 has made these printers a bit more difficult to use because the print drivers are not re-issued once a model is withdrawn. That can be overcome. To use the printers with Windows 7 use the Vista drivers in compatability mode. In terms of their phyical print abilities this series are not greatly outperformed by newer models - photo print might be a bit better.

There are certainly arguments in favour of of upgrading to a bigger machine if your work is time-sensitive or reliability and production quantities are a major issue. There are arguments in favour of inkjets like the OfficeJet Pro series if you want a low-cost multifunction machine with a scanner. There are also arguments in favour of keeping the CLJ 2600 series going - it has bigger cartridges than recent models and a fairly low cost per copy, particularly using refurbished cartridges..

Refurbished Cartridges

A big benefit of older printer designs like this is that you can cut costs by using refurbished cartridges and simply keeping other bits like the fuser and ETB going until they drop. Refurbed cartridges aren't so readily available for newer printers, or aren't so low cost.

Reliability is a problem with refurbished cartridges. As the brand-name printer manufacturers point out, refurbed cartridges give more problems. So if you are running a hotel reception where everyone is in neat white shirts and things are very time-critical refurbished cartridges probably aren't for you. On the other hand if you are running the back office and want to get some flyers out to drum up business then getting the little old color laserjet churning away cheaply may be precisely what you want - even if there is a danger of getting a bit of toner on your hands.

Fault Finding

Faults often turn out to be trivial, something like a contact not making properly, perhaps due to toner contamination. Finding the specific fault can take quite a lot of knowledge. Brand manufacturers are correct to say refurbished and compatible cartridges are never as good and sometimes downright faulty -but the problems can often be spotted and fixed.

The original aim in making print cartridges back in the 1980s was to simplify fault finding, allowing people to have personal copiers and laser printers without needing to schedule appointments for the copier engineer. About three-quarters of the failure prone parts of mono printer are wrapped up in the cartridge, so solving a fault is often be just a matter of changing the cartridge. There are a few problems:

Colour print needs four print processes, so in a colour laser printer any one of the four cartridges could give trouble. Isolate problems by printing test pages one colour at a time, or with distinct colour bars like the test pages for the color LaserJet 2600. Some printers (like this one) do allow the cartridges to be swapped round for test purposes.

Besides the cartridges a printer has a fuser, which will age and fail probably at about 100,000 pages in the CLJ_2600 series. Fusers usually give distinctive failure patterns. Printer electronics can spot and report fuser heater failure, it may spot breakup of the heated film in the fuser. Contamination on the fuser film will give irregular shaped but regularly spaced blotches in the print. There is more about spotting faults in the fuser and changing ithere.

The other main source of problems is the Electrostatic Transfer Belt or ETB. It may have a shorter life than the fuser, probably between 50,000 and 100,000 pages. There is more on ithere.

Cartridges became rather expensive making people reluctant to treat them as disposable. However it's just one of the costs of colour print - from time to time one cartridge will give trouble and has to be removed before it is exhausted. With a bit of understanding it is often possible to see what might be going wrong.

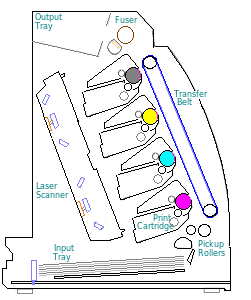

Machine Layout

Cartridges are arranged in a stack inside the body of the printer. The transfer belt is in the door of the printer. In use, the belt closes against the cartridges and as it does levers open the cartridge doors exposing the organic photoconductor or OPC.

When a page is printed, the pickup roller kicks the paper out of the tray into the registration station, it then attaches to the Electrostatic Transfer Belt or ETB. The belt carries the page up through the printer across the cartridges, one after another. As the paper moves up the stack of cartrides it passes over the OPC drums. (OPC is the abbreviation for Organic Photo Conductor. Each OPC is scanned as it turns by a laser and that creates an image. As the paper passes up the belt it gathers an image from each OPC.

When paper leaves the stack of cartridges it passes through the fuser which adheres the four images to the paper using a combination of heat and pressure.

One of the things that attracts people to laser printers is their reputation for reliability. This reliability is based on continuity of action. Laser mirrors scan, drum and rollers turn in one continual action.

Cartridge Construction

This outline of how a cartridge is put together is intended to help people with fault diagnosis rather than to repair or refill cartridges. Be aware that taking a cartridge to bits can be a messy business.

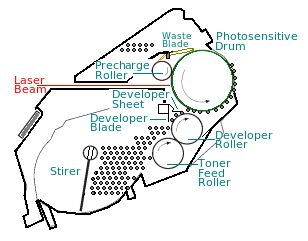

Cartridges for the Color Laserjet 2600 series are made in two halves. The lower part contains toner and developer, and the upper part the OPC drum, precharge roller and and waste toner scraper.

The two parts are joined by hinge pins inserted towards the top rear and clamped together by springs at the lower front.

Precharge

Action centers around the OPC drum. The OPC drum rotates past the precharge roller first. The precharge roller is near the top of the cartridge just behind the OPC drum and pressed up against it by springs at either side. It is electrically connected to the printer electronics through the metal hinge-pin in the blue handle on the right of the cartridge (left side as you are inserting it). The drum gets an initial uniform surface charge from this.

Print problems in a refurbished cartridge can come from a poor electrical contact to the hinge-pin because it has been damaged - or because the metal contacts inside the cartridge have been damaged or misplaced during re-manufacture (its easy to do).The precharge roller is in a conductive plastic bearing at one side and this should be lubricated with a drop of conductive grease. Resistance from the roller metal shaft to the metal pin should probably be below 300 Ohms. With an ordinary multimeter the resistance of the roller material itself was unmeasureable - above 20 megaohms.

Laser Scan

Having gained a charge the OPC drum rotates past a slot between the upper and lower halves of the cartridge body. The laser beam scans it's raster pattern across the width of the slot. The drum's green plastic surface has three layers: the upper one is the charge carrier, and the lowest is the aluminium body of the drum itself. The middle layer is photoelectrically active, when hit with light it conducts so the charge from the top layer leaks away into the aluminium drum. The drum has an electrical contact inside the drive shaft on the left side (right as you insert it). As a result of its pre-charge and selectiver laser exposure the drum now carries a latent image

in static electricity.

Developer

The latent image carries on over the developer

roller. Developer carries a thin layer of toner with it's own charge, partly created by the rubbing action of the feed mechanism (a triboelectric charge) and partly by a high voltage applied to the developer roller itself through contacts on the right of the printer - in this case it is the square metal contact exposed towards the bottom rear of the cartridge on the left as you are inserting it. Where charges differ the fine toner powder adheres to the OPC drum as a physical image. If you stop the printer in mid action a little bit of this image will be visible when the drum shutters are opened, just before it gets to the page. (We don't recommend doing this when there is no need, as it can create problems butstop testsare sometimes used in fault diagnosis. ).

The developer roller is aluminium with a black coating. One source says the coating is teflon but measurement seems to suggest it is conductive, although that might be exposed metal showing through.

The developer roller is supplied with toner by a stirrer or agitator which continually pushes toner in the supply compartment up and forward and by the toner feed roller which is a foam rubber roller loaded with toner in close contact to the developer. The toner layer is then controlled by a doctor blade set a few microns wide to allow only a fine layer of toner to move out and toward the drum. The purpose of the developer sheet seems to be to give that layer it's final charge and layer thickness.

Toner with one charge from the developer is attracted to the latent image in static on the OPC drum. The drum / developer pair have now created an image in one of the print process colours. Any remaining toner on the developer simply travels back round. Residual toner on the drum is craped into the waste holder.

A page to be printed should be adhered by static to the Electrostatic Transfer Belt (ETB) and travelling past the OPC drum. Behind the ETB belt itself are transfer rollers which attract the toner from the drum surface onto the paper. The transfer rollers connect to the high voltage electronics through tin-plate connectors on down the right side of the ETB - left as you look at it with the door open) and mating springs on the printer body.

Waste Scraper Blade

A few percent of the toner will not transfer onto the paper and remains on the drum. These toner grains may be malformed or carrying the wrong charge. It is removed by the scraper blade at the top of the drum and is held in the waste compartment at the top of the cartridge. In the CLJ 2600 series cartridge waste handling is nothing more elaborate than the blade and compartment, there is no mechanism forcing toner to the back, no illumination of the blade to entirely discharge the drum - just the blade and a small compartment.

Separation from the ETB

At the top of the printer the page separates from the ETB. This is largely mechanical, the ETB turns quite sharply and goes under the calibration assembly. Paper doesn't make the turn and goes past a discharge comb - a metal strip with a set of points, visually not unlike the tear-off strip on a box of aluminium foil.

Fuser

Paper (or whatever print media is used) exits through the fuser where heat and pressure make the toner adhere. For transparencies and suchlike the fuser temperature is usually adjusted downward and the printer slows down to get adequate fusing at the lower temperature. Some printers automatically detect use of a transparency but we don't think this one does.

Cleaning

Not all of the toner transfers where it should go. Some makes tiny random dots on the page, if there are just a few of these it is unnoticeable and not a problem, but they should not build to a visible background. Some toner innevitably tranfers where it should not, to the exposed edges of the transfer belt, and even to electrical contacts. There is no question that this semi-random movement and the amount of waste toner is made worse when the toner powder is not a good match for the machine or if the fine engineering tollerances expected are not well mached by cartridges - both things that can happen with recycled, refilled, and re-manufactured cartridges.

The printer also prints directly onto the ETB at times, notably when told to calibrate. Rather than taking paper from the tray and printing normally during calibration the printer makes patterns on the ETB and then rotates it to the density and registration sensor

To clean toner off the transfer belt the printer uses the cartridges. Voltages are changed so that toner is attracted off the belt and onto the OPC surface and then into the cartridge waste chamber. The magenta cartridge, being the first the belt passes after the desity and registration unit, is likely to get most waste. Waste in the magenta chamber looks a little darker than pure magenta, presumably because there is a mixture of toner grains in there.

Transfer Voltages

The voltage on each of the electrical contacts, and on the transfer rollers behind the belt vary as the image is built up. It is quite a complicated pattern. It is possible to measure the voltages using a high voltage probe but obviously this needs some caution. The maximum is something in excess of 7,000 volts. Whilst the power supply circuits delivering this are small and basically designed to provide almost-static electricity they could prove fatal to people. They would also damage any meter not equipped with a high voltage probe.

Manipulating voltages in this way is obviously complicated and it is no surprise to find the high voltage power supply board that does the job takes up most of the right hand side of the printer.

If the voltages aren't correct then either the page image will suffer or there will be toner in the wrong places, an excess of it on the ETB or more than usual on the cartridge contact springs. Look inside the drum shutters - if there is a great deal of toner inside a drum shutter then that cartridge is struggling. Turn the printer off, clean the mess up, then run a couple of cleaning pages and a calibration.

Voltage faults are most likely to be the general state of cleanliness in the printer and / or an issue created by refurbished cartridges.

The printer's other noted fault - misalignment - also seems to be associated with use of refurbished cartridges.

Cartridges and Repairs

The general approach to fixing modern printers is supposed to be to change the cartridges. An easy user change of the main works in a printer was the original purpose of creating cartridges.

In recent times there has been a problem because the price of cartridges is now high compared to the the price of a printer. In the early 1990s mono laser printers like the LaserJet III cost about £1,200 and £60 for a print cartridge (PC-User October 1990). So if the printer went wrong people might cuss a bit but they changed the cartridge

Printer manufacturers found selling cartridges easy and profitable. Costs in IT generally have fallen as the market grew bigger, but the cost of printers has fallen a great deal

Twenty years later a roughly equivalent printer has dropped in price to just £200-£300. Cartridge prices have shifted as well, they tend to be a bit lower in capacity and priced at £50 or so. A colour laser printer has four cartridges and for the CLJ 2600 series those have a manufacturers price of about £50 each. So to check a simple fault in a printer people might need to invest as much in cartridges as the printer cost.

There are two ways to treat this

- Treat the printer as disposable - the whole £200+ machine (and any spare cartridges you do have) goes in the bin

- Treat the cartridge as repairable.

The Q6000A series cartridges for these printers are not very easy to dismantle, never mind repair.

The key points are the springs at the front and the hinge-pins at the back. The hinge pins are not designed to be removed and the OPC drum is held in by the blue plastic handles that are glued in place.

There are supplies for professional refurbishers.

These cartridges aren't easy to work on. Like all work on cartridges toner will attempt to escape everywhere. Most manufacturers say the main toner ingredients are not hazardous in normal use - and the main ingredients are styrene acrylate which is roughly equivalent to poster paint. However they don't make clear what the colourants are and dismantling the thing scarcely counts as the intended use.

Copyright G Huskinson & MindMachine Associates Ltd 2012