Note: The kits with the ridiculous price are the HP "official" product with the instruction sheet. Since the instructions are simple (read on) all websites ship the lower cost unofficial version originally made up for the LJ-4200 and LJ-4700C.

HP CB506-67904 Roller Kit for P4014 Series Cassette Trays 2, 3, 4, 5 & 6.

HP produce the CB506-67904 Roller Kit to fix paper feed problems and "jam" messages from Trays 2, 3, 4, 5, 6 of the LaserJet P4014 series (P4014, P4015 and P4515). The same kit fits predecessors like the LaserJet 4200 and successors like the Enterprise 600 M601 series (The LJ-M601, LJ-M602 and LJ-M603 printers). It doesn't take IBM Watson to deduce it fits the M604 series as well. HP has created different product codes for kits with the same rollers - and some confusion (see Google Images for the code)

Tray 2 is the cassette tray (pull-out tray). It pulls out from the lower front of the printer. The kit is needed if the printer often gives paper jams and "Error 13" from the cassette. Confirm the feed rollers really are the problem by printing from tray-1 instead it usually gets a lot less wear.

The (optional) additional trays 3,4,5,6 fit under the printer(the printer sits on top of them - see below). They use the same set of rollers.

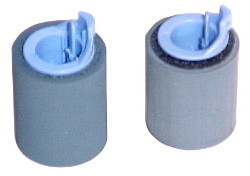

Rollers are available individually, but it is normal to replace them with a kit. Analysing which specific roller is the cause of a tray 2 paper feed problem can take some time and is futile as they will both be worn. The RM1-0036 (white core) roller may not be worn - in which case if you got a spare in the kit save it against future need.

The HP official kit has three rollers and an installation instruction leaflet

- 1 x RM1-0036 Tray 2 Pickup Roller

- 2 x RM1-0037 Tray 2 Feed and Separation Roller

(or did when we opened one)

Need for a kit

This printer uses soft pickup and feed rollers with a textured surface. This approach is common in recent laser printers, the advantage of soft rollers is reliable pickup and movement across quite a wide variety of paper and other media types. A potential disadvantage is that roller texture will wear away and then the number of misfeeds rises. The printer will start to give "Error 13" paper jams from time to time and progressively get worse. If a printer is misbehaving users notice, it can also be seen in the event log (Administration > Troubleshooting > Print Event Log)

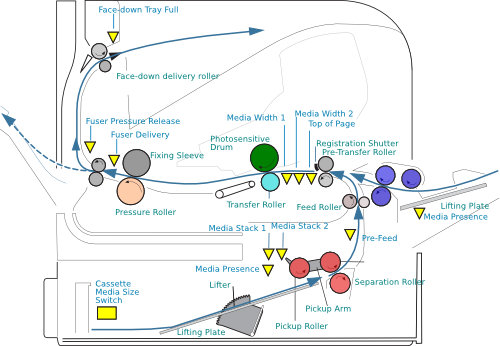

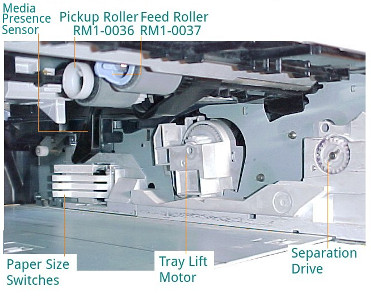

Arrangement of parts in the LaserJet M601 series. There are a lot of rollers but most are hard plastics and rubber and do not age much. However the pickup rollers in the cassette (and in the MP tray, if you use it) are soft rubber and do wear out.

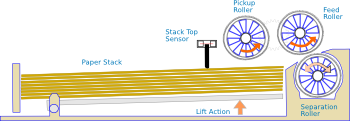

The M601 series (like the P4014 before it) uses a triple-roller mechanism with a pickup, feed and separation roller. The pickup roller (white core RM1-0036) pushes paper into the nip-point between the feed and separation rollers (both RM1-0037 with blue cores). The feed roller overcomes the separation roller and pushes single sheets forward. If there is a double-feed the separation roller pushes additional sheets back on the stack. (Very similar mechanisms are now used by most high-end printers and copiers).

Feed and separation rollers are prone to wear because they work against one another. The feed roller on top attempts to push the paper into the printers paper feed path. The separation roller underneath is driven by a cog on the side of the cassette tray in a direction that would push sheets back - but it's strength is reduced by a torque limiter, so generally it turns with the feed roller. Or at least, that is what happens if only one sheet feeds. However paper is a bit inclined to be sticky or ill-cut and sometimes two or more sheets move at the same time. When that happens the separation roller will get it's way and push those extra sheets back into the tray until the next feed. The two rollers are working against one another so over time they do wear out.

The same roller set is used in every cassette on a large machine - according to the service manual this includes the 1500 sheet front loading feeder. (Which suggests designers can re-use an idea if they want to).

Roller Life

How long rollers will last might be determined statistically (HP presumably have figures, but we do not). It will depend on page count, media type, roller material and user tolerance. Some designs of printer prompt for a kit at a specific page count (100,000 say), but to be useful a prompt must be given before malfunctions get annoying. Fixed time prompts waste resources. The LJ-M601 will prompt for a maintenance kit comprising a fuser and a set of pickup and feed rollers at 200,000 pages by default and the maintenance kit is exhausted at 225,000 pages. Experience is that rollers are often working at 60,000 ++ pages but the texture has gone.

RM1-0037 feed rollers. That on the left is fresh from the pack. On the right is a worn one showing a rather shiny surface and uneven ridges of wear. They do seem to change colour a bit as they age as well. The roller here had probably done 86,000 pages and was still functioning well with ordinary office paper. Heavy, glossy media like labels would give trouble.

There is more on paper-feed problems in the page on the cassette tray RM1-4559, and a considerable amount of generic information here. The same kitis used in the P4014 and predecessors so pages on feed problems for those might be useful as well.

HP maintenance kits CF065A (and CB389A) don't include the pickup roller RM1-0036 - hence if you don't need to change it now save it for later.

The counterpart for Tray 1 - the multi-purpose tray built in to the front of the printer is CB506-67905 .

The CB506-67904 kit contains 3 rollers:

Feed and separation rollers are identical which makes some sense given the work they do. Both rollers are RM1-0037

Changing Rollers

The rollers are easy to change, HP regard it as a simple job for users (and will only do it under warranty if paid a call-out fee). If you are not familiar with the job, seeing into the dark recess where the cassette goes is the only problem - some office lighting casts heavy shadows. We suggest changing the cassette roller first because it is easy to see. Take the cassette completely out of the machine, which involves lifting it slightly as the rear emerges. It is probably best to lift any paper out. There is a little access hatch beside the roller, open it. There is a tab on the roller and a latch, pull the latch toward the tab and the roller is free of it's shaft. Hold the new roller by its tab and push it on. Locating recesses on the roller fit over lugs on the torque limiter. The torque limiter has a recess that slots over a split-pin in the axle. The roller latch clicks home when it is on correctly.

The roller(s) in the printer work in much the same way; a difference is that you may need a torch to see them in the cassette recess. Whether you need to change pickup roller RM1-0036, the white-cored roller at the back, is a judgement call. If you drove to site to do the job then definitely - but users are supposed to be able to change these themselves. Check if it seems worn.

When you install these rollers, make sure that the rollers seat properly on the drive gear tabs. Each roller has a location recess that fits onto a lug and a tab that clicks onto the shaft. The rollers will only click into place when they are correct. If the roller will easily pull back off the shaft it is mis-seated (rotate it a bit until it slides into place).

Jam Checklist

Changing the rollers usually fixes paper-jam problems. In the unlikely event that changing the rollers doesn't fix feed problems here is a check-list.

- Try feeding paper from tray 1, the multipurpose fold-down tray on the front. You may not normally use this tray but if it will work well whilst cassette tray-2 won't that strongly suggests where the problem lies.

- Check that the paper meets the requirements for the printer in the user guide (briefly, 60-120gsm). The user guide can easily be found online, search for

Part number: CE988-90901 filetype:pdf

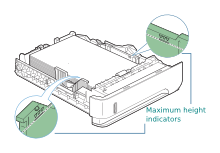

. Alternatively, get a completely different ream of ordinary office paper and try that. - Don't overfill the tray. Trays take 500 sheets of paper about 80gsm thick. That doesn't mean there is a firm guarantee that you can empty a ream of paper into the tray and have it work properly. Some printers have 550 sheet trays and that avoids the problem, but these don't. The guides have a fill-mark ∇∇∇

- Adjust the paper guides close to the paper but not to the point where they grip it firmly. The tray guides have "detents" and will click into position on standard paper sizes. The RM1-4559 cassette is not appropriate to non-standard sizes and should be swapped for custom media cassette CB527A.

- Try turning the paper over and the other way round. Paper has a grain direction and is sometimes mechanically guillotined so that the edges fold slightly.

- Paper is more prone to damp than people often suppose. If a printer commonly misfeeds on a Monday morning that may be damp getting the first pages over the weekend. A characteristic sign is that the pages that succeed in printing curl in the output tray. Paper like that may make it through the printer but not through the duplexer. Duplexer problems won't be cured by changing pickup rollers.

- If paper won't feed, suspect an obstruction. Take the cassette, cartridge and if necessary the fuser out and examine the paper path for obstructions - staples, labels, human hair and other foreign objects. There is about four inches of "throat" where paper feeds from the cassette to registration - its interior isn't visible without dismantling the printer. Medium-sized card can be poked through to confirm nothing is caught.

- There is a minor issue with the M601 series. In order to reduce noise levels HP put an assembly in the paper feed throat that narrows it. It has increased misfeeds a bit. Removing it is definitely a technician job, as it involves removing the MP tray mechanism.

- … and finally … if all else fails you may have the dreaded solenoid problem. The error log will show a cluster of 13.02. 13.03 and 13.98. Put the printer in Diagnostics > Paper Path and set it for 10 prints or so. If the solenoids are OK the clicking of the solenoid is steady, if it is sticking there is a characteristic wrong beat. Its a technician job to change the solenoid - but not a ghastly one.

If nothing seems to work we have a generic page on printer paper jams and misfeeds here.

HP make at least four kits that contain some or all of these rollers:

Maintenance kit CB389A (P4014 series) CF065A (M601 series) or F2G77A (M604 series) contain a fuser and the feed separation rollers. Field service engineers and site technicians have become used to asking purchasing for a maintenance kit. Ordinarily, maintenance kits contain the set of rollers for one tray, however the CB389A contains 10 RM1-0037 and a transfer roller CB506-67903 /RM1-5462 and (sometimes/always) no RM1-0036 - which engineers then complain about. Google images shows the confusion.

HP Part CE988-67904 is supposed to be the kit for the M601 series. Sometimes it is suggested it has 5 full sets of rollers, enough for a full tower. That would sort-of fit with CB389A and CF065A and explain it's high price. Dissapointingly, has just the three rollers and a leaflet and partsurfer confirms that is intended.

HP Part E6B67-67905 is the kit for the M604 series. The wording sometimes says it is a "Tray 2 through X roller kit" and Partsurfer says "Paper feed roller assembly - Part of tray 2-6 roller kit". Time will tell, there are non in distribution in June 2015 (the printer is quite new) but we think it will have the same three rollers.

HP then make the roller kit we are discussing here as CB506-67904, it should have 3 rollers as shown, and the green leaflet.

Having three kits for three printers might seem to make sense. The explanatory leaflet doesn't need to change much, since this is one of HP's pictorial, language-free explanations. The rollers in the printers are the same, and so is the job of changing them.

Problems arise firstly:

- because the official HP kits are completely different prices from one another and between vendors. We don't know whether that is HP or distributor policy but suspect a bit of both.

- and because HP have been known to ommit parts from a kit without notice - leaving vendors looking silly.

This creates a problem because spares is all about logistics and support costs. HP hugely increase the spares and support costs if they turn two rollers into more than four kits. It is even worse if they switch what is in kits.

If you find what seems like a bargain that is because the distributor or spares dealer has got fed up and decided to make their own kits - from HP, Canon or even clone parts.

Buying Options

We would like to say "here's the kit, and all you need to do is buy it". That is all most sites do and that is what we primarily do on the catalog pages.

If only it were that simple !

HP produce the official CB506-67904 kit. From distribution figures we can see it has been selling in tiny numbers up to June 2015. UK distributors list the kit but only carry stock of two or three - often at crazy prices. Almost everyone (including ourselves) tends to automatically ship the equivalent Canon parts - there is a moderately large market. Some people seem to copy the HP information sheet CB506-90946 but that is evil and we presume they risk a sharp rebuke from HP's lawyers. (We don't need to; this page gives more information).

These rollers have been around for some time, and are used in a variety of printers. Partly because of that there are several varieties or roller - and even more possibilites for kits!

HP Originals

In June 2015 Web majority logic is solidly of the opinion that the RM1-0037 roller and Q7829-67925 are the same. Our research suggests that ain't necessarily so. RM1-0037-020 is made by Canon and has a foam fill. Q7829-67925 seems to be HP's variant of the part and has a solid rubber fill. Nothing else seems changed, surface material seems the same and indeed the rollers seem to wear in the same fashion. We can suggest ways behaviour might differ, for instance the HP rollers weigh more and the velocity of pressure waves will be different in them - but we haven't yet found anything from HP describing the benefit of one over the other.

Some organisations such as hospitals have a policy of only using parts by the manufacturer. Because it is rarely made clear whether CB506-67904 uses HP, Canon or clone parts they will have been buying "whatever" where they should be buying the official kit. We list the official kit but the pricing is offputting. We did have reasonable pricing but it did depend on small numbers stocked by one UK distributor - and when we asked it turned out they were making up their own kit ! HP's Distributors have the kits, but usually in small numbers at silly prices. Distributors appear to think HP is "pulling the wool" with their prices and only stock a couple of examples.

Canon Parts

Almost every kit on the market uses the Canon parts. With most printers that is fine because Canon build the print engine. Canon build other printers that use this roller. In the P4014/ M601/ M604 case there is no Canon equivalent engine and HP have specifically said of RM1-0037-020CN that it is replaced by Q7829-67925. HP haven't said why, or anything about that not being so for its neighbouring roller RM1-0036-020CN). There is much more on the stange story of RM1-0037 here.

Clones

Whilst there may be a difference between HP and Canon parts the more worrying difference is usually between either of the original makers and the "third party compatibles" or "clones".

Printers that use the RM1-0036 / RM1-0037 rollers sell in great numbers. The RM1-0037 in particular naturally sell in large numbers worldwide and so great numbers of Asian vendors claim to be making parts for HP. At least a couple of European and US companies claim to have "compatibles" they made themselves, under their own label. This inspires eBay and Amazon vendors to offer kits at low prices. In principle it is possible to make a good clone; in practice they usually don't bother and just aim at low prices. If a kit doesn't state the parts source then it is likely to use parts of dubious provenance.

Simplification

Provenance of parts is a recurring issue in spares. Things like rollers are made in hundreds of thousands and then sell for anything between £3 and £50 - depending on what the manufacturer and the various other cogs in the chain think they can get away with. This goes for the distributors, for dealers and vendors - and definitely for the third-party clone makers. Unfortunately that goes for HP themselves because they think being open about the relationship with Canon would spoil their brand.

What we do is try to set out a choice. We are prejudiced against clone parts and don't use them for these kits because there is no need. We normally use Canon; we will use HP if a distributor offers a better price. HP parts are not automatically dearer than Canon - their inter-company arrangements are unknown to us. We currently make up most kits ourselves, but we offer the HP version as well.

Old Rollers

We would love to tell you how to recycle rollers. Regrettably we have yet to find anything sensible to do with old rollers. Cats enjoy kicking them around and if the rubber is EPDM then its biologically inert so it won't harm them. These rollers are the wrong size for dogs, Maine Coons and children; they might swallow them. The tyre simply wears out and is then no use. Some rollers (Lexmark) can have a new tyre put on the core. However with the RM1-0037 it is quite difficult to get a tyre off the core and putting a new tyre on would involve rough handling that would possibly damage the material.

There is a great diversity of printers. Those in this kit are amongst the most common - as indicated by the fact that there are "clones" on the market. Even so, the effort of collecting rollers in order to have sufficient to make recycling worthwhile looks futile. So its the general plastics waste-stream for them?

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site useage patterns.