HP Original Cartridges

(The "X" size won't fit the M601)

Reliable Remanufactured Cartridges

Tray 1 Roller Kit

HP CE988-67905 Roller Kit for M600 Series Printer MP Tray 1.

HP produce the CE988-67905 Roller Kit to fix paper feed problems from Tray-1 on M601, M602 and M603 printers and the related M630 Multifunction printer/scanner machine. The kit is identical to CB506-67905 produced for the P4014 series except perhaps for the leaflet (but the printers don't look very different, the trays are almost identical and the rollers are the same).

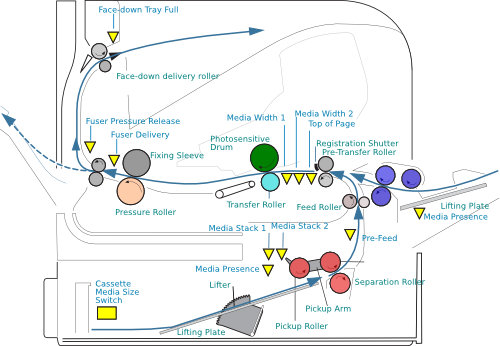

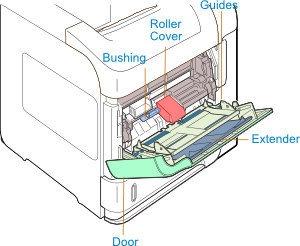

Tray 1 is the drop down tray on the front of the printer. It pulls out from the upper front of the printer and provides some guides aiming more or less straight into the registration station. If you occasionally want to handle envelopes or letterhead it saves reloading the cassette and the expense of buying the special accessories to handle those things.

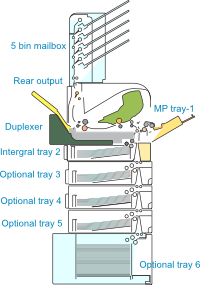

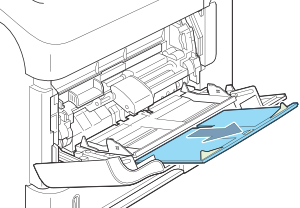

An additional advantage that makes the tray "MultiPurpose" is that is will feed a wider variety of materials than the standard cassette. It can handle narrow media (also possible with the CB527A custom media cassette ). Working to the rear drop down tray it will also handle much stiffer material, up to 200 gsm according to the user guide. This is possible because material passes more nearly straight through the printer, rather than the "S" shaped paper path from cassette to top output bin. The MP tray can print to the top output bin, but the printer won't handle quite such a range of media in that case.

The P4014 and M601 are a bit unusual in providing a three-roller feed set for the MP tray - a lot of printer manufacturers cut costs here and use the cheaper single roller and pad. An excuse for being a cheapskate where the MP tray is concerned is that many people don't use it much.

Quite a few users don't even know the MP tray is there! This can cause confusion because people intermittently buy rollers for tray-1 and expect them to fit the cassette - which they don't.

The MP tray on the P4014 and M601 can be neglected because it tends to be a "workgroup" printer shared by three or four people and they may not all be within easy reach. Buying the accessories and making a tower solves that.

The MP tray has a nominal capacity of 100 sheets - or actually a centimetre thickness which for ordinary office paper is the same thing. That might work out as few as ten envelopes. Envelopes containing an air pocket tend to fill the tray up too much - they are a bad idea because they wrinkle and jam in the fuser. (HP sell all kinds of recommended media including envelopes).

On the other hand these machines get used as production printers for tasks like small-run publishing and even despatch labelling. Those jobs might well make frequent use of the MP tray and value the reliable 3-roller feed.

RL1-1641

RL1-1641 RL1-1663

RL1-1663 RL1-1654

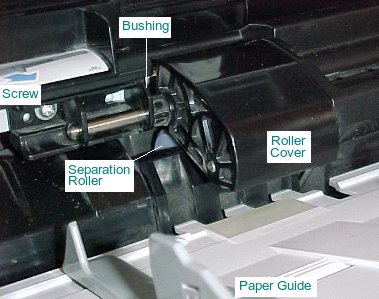

RL1-1654MP tray rollers are not the same as cassette rollers - which is odd as these printers manage every other task with a similar set of rollers. The MP tray has limited space as it is supposed to fold up unobtrusively, so there isn't space for the standard roller set. As a point of curiosity, the tray-1 rollers have a black rubber working surface rather than the grey rubber used on the cassette tray-2 kit. They are smaller in diameter and axial length as well. A close look at them suggests three different construction methods, with the feed and separation rollers being the same diameter but the separation roller has one rubber layer where the feed roller has two.

Only the separation roller has a blue core which HP uses to indicate "user changeable". The pickup and feed rollers don't have the blue core - although they are actually easier to change. The pickup roller has a cog on the side. Cogs tend to be made of POM (Polyoxymethylene) which can be made coloured but usually isn't.

It is normal to replace the pickup, feed and separation rollers at the same time, as analysing which roller is the cause of a paper feed problem can take some time. Hence they tend to be sold as a kit.

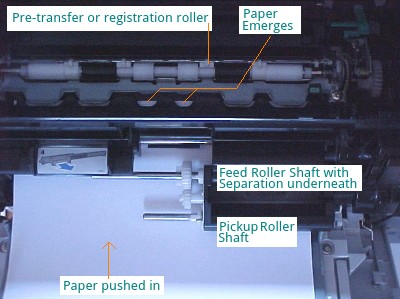

Feed and separation rollers work against one another. The pickup roller pushes paper into the nip-path between them. The feed roller pushes paper into the printer but the separation roller underneath attempting to rotate the other way - pushing sheets back to the tray. The two rollers are working against one another so they do wear out. There is a fuller explanation on the cassette page.

Brief Instructions

HP intends these kits to be changed by users. Changing the MP rollers is impenetrable at first sight. Everything is held in place by one screw to the left of the roller housing. The screw needs to be removed temporarily.

With the screw removed the bushing slides left and off the shaft; note which way round it goes. The roller cover slides left and off, exposing the rollers.

The pickup roller and feed roller are easily pulled off their respective shafts.

The separation roller is a somewhat buried in the mechanism. A cover on the left pushes down to reveal it a bit more and the roller has a long blue stalk. Use the stalk to pull the roller off it's shaft.

Installing new rollers is just a matter of reversing the dismantling process.

Make sure that the rollers lock into place on the drive gear tabs.

Rollers and cover will only click into place when they are correct.

It might be a good idea to check the rollers by removing them and having a look before buying a kit. At the outset the job might looks a bit daunting but it proves easy.

Rollers give away their own history; if they have no surface texture or have brittled with age they won't work very well. It helps to be a bit short sighted because a roller can look textured when the rubber surface has been worn down and cracked.

In the unlikely event that changing the rollers doesn't fix feed problems here is a brief checklist.

Using the MP Tray

- Adjust the paper guides close to the paper but not to the point where they grip it firmly. Use the tray extender for long media.

- Don't overfill the tray. The tray takes up to 100 sheets of paper about 80gsm thick. It will take less of thicker or heavier materials.

- Generally, avoid interfering with the action, the printer takes pages in swiftly, although it is often a bit slower from the MP tray than from the cassette if the media type in the computer driver indicates that.

- If there are misfeeds try turning the paper over and the other way round. Paper has a grain direction and is sometimes guillotined so that the edges fold slightly and that can interfere.

- Suspect an obstruction. Take the cartridge out and push a piece of paper through the slot- it should emerge cleanly into the registration area.

Checking the MP Tray Feed Path

One of the nice things about the tray-1 feed path is that it is straight -forward to check. Take the cartridge out and slide a piece of paper in - it should visibly emerge in the registration area. If it doesn't you have an obstruction. (And if it's a sticky label best of luck).

Buying Options

| As code | |

| CB506-67905 | In June 2015 no UK distributor seemed to have more than half a dozen. |

| CE988-67905 | In June 2015 one UK distributor had a dozen in stock at a price that beats buying the rollers. |

| As code |

As quite often happens with this sort of thing some distributors are charging twice as much as others.

| RL1-1641 Pickup Roller Only 3 distributors in the UK even mention it. No apparent stock. |

| RL1-1663 Feed Roller No distributors list originals. One lists MicroSpareParts clone but holds 5 in stock. |

| RL1-1654 Separation Roller For some reason this seems to have inspires a bit of interest, three distributors list it and one has a small stock, but not at an attractive price. |

Non of these rollers is used in anything but the P4014 and M601 series. Furthermore unlike the CB506-67904 kit they are required infrequently.

Should you want to buy one of these you will almost certainly get originals wherever you buy. HP's price to distribution appears to be reasonable as no distributor is charging the phenomenal prices seen for the tray 2 kits. - However some are charging twice the price of others. No distributor has a complete set or rollers in stock. The surprise is that one of the third-party makers has bothered - but just with one of the rollers needed to make the set.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site useage patterns.