HP LaserJet M604, M605, M606 Printers

CF281A and CF281X Print Cartridges, spotting faults and finding fixes.

The CF281A and CF281X are print cartridges for HP's LaserJet M604 series A4 mono laser printers. They also fit the related M630 MFP.

Cartridge construction is very similar to HP's CE390A used in the Laserjet M601, M602 and M603, which are the M604 series predecessor - and indeed to the P4014

Our experience has been that HP printers and cartridges are reliable, but of course anything mechanical can develop a fault. (It is difficult to establish reliability and returns rates, statistics for this sort of thing tend to be secret, suspect or both.

HP Cartridge Quality

HP's M604 series cartridges give one of the computer print industry's lowest operating costs: 1p per copy for the 81A and 0.7p for the big 81X cartridge. These all-in-one cartridges are very easy to use and print defects are usually cleared by just changing the cartridge.

HP original cartridges are highly reliable - so you should not need to read this essay.

Some people will want to get costs down further and that is certainly possible - but you may need some technical knowledge to differentiate between cartridge and printer faults. If that has become a problem, read on.

Print cartridges were originally conceived as cheap, easily replaced parts to solve printer faults. One disadvantage with a big cartridge like the CF281X is that at £150 people might be reluctant to throw one out or send it to the recycler.

As you probably know refilled and compatible cartridges are are more likely to give problems. Print problems caused by a cartridge aren't always straight-forward so we recommend having an HP original cartridge available for test purposes even if you intend to use something else for the bulk of your printing.

Outline Of a Laser Printer

Printing proceeds as follows

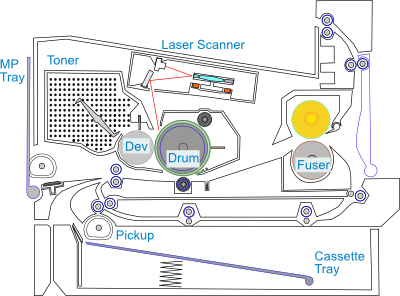

- A page received by the electronics as a print language is converted to a bitmap that can be reproduced by the laser scanner as the rollers turn.

- The drum is coated in Organic PhotoConductor (OPC). This OPC layer holds an electrical charge in the dark but where it is struck by the laser that charge drains away.

- The developer roller carries a thin layer of toner powder against the drum where the static charge attracts or repels it (in printers it is usually repelled or "write black" because that uses the laser less.)

- Meanwhile paper has been pushed off the stack to be between the drum and transfer roller. The image is stripped off the drum onto the paper by a high voltage on the transfer roller.

- The paper passes on through the fuser and in most modern printers is carried up and over to land on the top of the machine.

Basics of Laser Print

Laser printers and photocopiers use a solid powder called toner rather than ink.

Fine particles are quite easily attracted by fields of static electric charge and that is the basic mechanism used by the copiers and laser printers.

Toner powder is almost always made from small plastic particles. At one time black plastic was ground into particles about 8-10 microns across in a machine called a ball-mill and this kind of powder is still used in photocopiers. Individual particles this small aren't directly visible but clusters of a few are. Copiers deal with text quite well but older machines give crude looking photographs; big toner particles are one of the things limiting the ability to print grey.

Toner is formed into an image by a drum, a metal cylinder coated in material that accepts and holds a static charge in the dark but which conducts in the light so that the charge weakens. Materials that can do this are "photoconductors" and many semiconductors can do this, silicon will work, as can sulphur. Selenium works well, as do some thin layers of plastic. Plastic photoconductors are known as Organic PhotoConductors or "OPCs". Almost all laser printers use OPC.

The drum turns and as it goes round its surface is first "precharged".

A scanning laser beam is used as a light source to selectively discharge parts of the drum surface. The result is a "latent image" - not yet visible, made from varying charges of static electricity.

The drum surface with its latent image passes close to a "developer" roller coated in the toner powder and an actual image forms on the drum.

Transferring the image from drum to page is the next step. The imaging system and the drum itself are arranged over the paper path. As the drum turns and the paper advances beneath it a highly charged transfer roller pulls the image across. The image is now on the paper in lose toner.

The fuser sticks the toner to paper. The fuser is heated to the point where toner is sticky so if it is pressed hard against the page it melds into the paper. HP use an "instant on" fuser with a ceramic heater that reaches temperature in seconds; they also use a low melting point toner that saves energy because the paper doesn't need to get so hot.

Toner Composition

Toners come in many types.

Plastics popular at the moment are styrene acrylics and polyesters. Very often the toner is grown in solution, this gives grains with diameters of 5 microns or less and a smooth surface approximating a sphere.

In the laser-print process toner moves by electrostatic forces. If an object like a toner particle is elongated or has spikes the distribution of electrostatic forces will be uneven. Toner grains will clump unevenly so that print is irregular in shape and thickness.

Small evenly sized spherical grains that respond in a proportionate way to electrical forces are best for printing.

Toner particles are not merely spheres of one thing. There are several hundred types of polyester. The outer surface of a toner grain needs good triboelectric charge characteristics (an ability to generate and hold the right amount of static). Triboelectric qualities are often helped by surface additives. As toner churns in the hopper these additives tend to abrade so a hard surface shell on the grains might be desirable - but runs counter to the need for a low melting point in the fuser.

HP mono printers use a magnetic toner. The toner itself is around 50% fine ground magnetite (iron oxide). This is used as an alternative transport mechanism in the developer process. The developer roller contains a magnet which helps control the flow of toner under the doctor blade.

Surface additives on toner particles are silica and titania (titanium dioxide), which enhance triboelectric charge production and flow characteristics and also reduce susceptibility to humidity.

Toner tends to stick to the rollers in the hot fuser. At one time it was common to coat the fuser rollers with silicone oil but that left a residue on the paper. These days the fuser roller is a Teflon coated film which has some ability to resist adhesion. That is further enhanced by incorporating some wax into the fuser particle structure, the wax is release by heating and makes the toner more adhesive to paper and less to the Teflon roller.

Toner particles may only be a few microns across but could have a wax core followed by a shell carrying the colourant and another giving the correct charge characteristics and adequate robustness in the toner hopper. Toner is specifically engineered for a job; using the wrong kind might not only give bad print, it may make a mess inside the printer. In serious cases toners have been known to coat fuser rollers so badly it cannot be cleaned off.

Buying HP original cartridges makes considerable sense. Toner is not just a dumb black powder, its a rather clever piece of manufacturing intended to work trouble-free with the printer.

Toner

Toner for recent printers like the M604 series is more sophisticated than that in the old copiers. The powder is much finer and as near spherical as possible which is achieved by growing the particles in an emulsion aggregation process. Individual particles are about 5 microns across and this allows better looking photographic grey and finer lines. Toner can be complicated: it has to stick to media including paper, labels and transparencies. It should transfer easily from developer to drum and then to the transfer roller. Toner must not stick to the rollers in the fuser.

Refilling and Recycling

Toner properties must be right or there can be long term problems, for instance the waste scraper blade may be unable to remove residue from the drum or there may be excessive friction between them. It is possible for bad toner to have a wider impact. For instance, bad toners have been known to snap the motor drive shaft in the P4014 series. Bad toner can also cause early failure of the fuser due to a build-up on the film. All the rollers in a cartridge wear out at different rates and replacing them is a judgement call.

Recycling cartridges by refilling looks easy, but is not always as straight-forward as it may seem. The CF281X is rather obviously an extended version of the CF281A. If you take an exhausted smaller cartridge, empty the waste toner, refill the hopper and either change the level chip or ignore the "empty" warnings the roller and blade components should clearly have some life in them.

At the moment HP most certainly won't sell you the toner and chip to do a good refill job. There is a recycling industry, some people such as digital publishers and marketing houses want print at the lowest possible price even if they have to learn some details about the printer. Sourcing parts to refill cartridges currently comes down to half a dozen franchises in Europe and the US and then to a confused market of Asian component producers selling via Alibaba. We think there would be mileage for HP in franchising such things down to high-street level. They don't do anything like that at present.

Fault Finding

There are three main parts to mono laser printers:

- Paper trays and pickup rollers, likely to be responsible for error 13 paper misfeeds early in the path. Paper misfeeds are not usually caused by a cartridge.

- Print cartridge and transfer roller, responsible for most print quality problems.

- Fuser and exit rollers, responsible for toner fixing, error 50 and some error 13 misfeeds late in the path.

The diagram and description above shows how laser printers work in broad terms. The principles apply to most mono laser printers. Colour printers usually have four toner-developer-drum processes and a transfer belt, so they are different.

HP's all-in-one cartridge contains all but one of the mechanical parts of the imaging process. The main bulk is the toner hopper. There are also a set of rollers: developer, organic photoconductor (OPC) and precharge roller. There is a stirrer in the toner hopper. A doctor blade helps controls how much toner moves from developer to drum and a wiper or scraper blade removes the 5% or so of toner that might remain on the drum after transfer and dumps that into the waste compartment in the "nose" of the cartridge.

The main mechanical part of the image generating process that is not in the cartridge is the transfer roller. This is located in the printer at the bottom of the cartridge well. It has a blue cog to help identify it as a user changeable part. A badly performing transfer roller will often result in rather faint print.

Print Cartridges

All of HP's mono cartridges tend to work much the same way. The cartridge is somewhat wedge shaped and inserts into the printer between the laser scanner unit and the paper transport, notably the transfer station.

At the rear of the cartridge a hopper holds the toner supply. Some cartridges raise this part into a bump; the bigger the bump the more it holds, ranging from as little as 1600 pages (about 80 grams of toner, enough for 3 reams of paper) to 25,000 pages in this case ( about a kilo of toner, enough for 10 boxes or 50 reams of paper).

Not very noticeably the cartridge is actually in two parts, clamped together. Separation is not noticeable because the end-pieces of the cartridge which are screwed on in this case hold the parts together. The toner hopper and developer roller form one part. The drum, precharge roller and waste hopper the other. With the 81A/81X cartridges the two are held apart during shipment and before use by the orange stopper inserted into the laser slot.

The developer roller has a bushing around it at either end. When the orange stopper is removed the developer roller springs forward and the bushings at either end engage the OPC drum roller giving a precise separation gap.

The toner hopper is actually separate as well. When an HP cartridge ships the toner is held back from the developer and drum by the strip of clear tape that is withdrawn by the orange ring-pull. If the tape doesn't withdraw properly then the cartridge won't print, or not down the side where the strip remains.

Internally the cartridge does largely have a separate drum, developer and toner; its just that HP don't think it worthwhile making those parts separable as might be found on Lexmark or Brother printers. In HP (and Canon's) judgement the convenience of a firm decision to "change the cartridge" as a first step in fault-finding outweighs any savings to be had from an imaging system in three parts.

The parts are separated by foam sealing gaskets. It is thought that the seals provide some damping from vibration caused by the stirring auger(s) in the toner hopper.

Print cartridges are intended as sealed units, or to put it in electronic industry terms there are "no user serviceable parts inside". Most people probably prefer things this way, opening up a toner cartridge certainly can make an amazing mess. Before even contemplating it, it is worth pointing out that toner is intended to turn paper pitch black and make it stay that way; it will do the same for carpets and clothing and only comes away from human skin with vigorous scrubbing. The health and safety data available suggest 81A - 81X toner is not medically hazardous. Toner is a damn nuisance if it gets out of the cartridge.

It is possible to take a cartridge to bits and swap components around; some recyclers and refurbishers do this, triaging components for good material. Others will strip the cartridge, replacing the wiper blade, the drum or perhaps all the components, keeping only the copyrighted and patented plastic shell. This is one of the problems with refillers and re-manufacturers - they are just as reluctant as HP to say what they actually are doing.

LaserJet M604. M605, M606 and M630 defects ruler

| Distance between Defects | Suspect Component | |

| 38 mm | 1.45 in | Primary Charge Roller (in cartridge) |

| 47 mm | 1.85 in | Transfer roller (below cartridge) |

| 63 mm | 2.48 in | Developing Roller (in cartridge)< |

| 94 mm | 3.70 in | OPC drum (in cartridge), fuser sleeve, fuser pressure roller. |

Slightly inconveniently the OPC drum, fuser sleeve and fuser pressure roller are all the same diameter so telling them apart will need visual inspection or a stop test.

Note that the diameters are identical to those for the M601 to within a millimetre which is probably just rounding or reporting error. The CE390A and CF281A are similar in almost all respects.

Finding Problems

Identifying cartridge problems doesn't usually require taking it to bits. Problems often show on just pushing the drum shutter back - scratches, finger marks or an odd absence or over-supply of toner.

The OPC drum metal coated with two different micron-thick layers of plastic: charge and transport layers. The drum coating is mechanically fragile, has to be clean to work and its properties decay in light. You have minutes rather than hours to examine a drum, and should avoid touching the green OPC surface unnecessarily.

It is easy to examine the drum. Turn the cartridge upside down and push the drum shutter open by one side. There is a warning on the shutter saying not to do this - however it sometimes proves helpful if you note the warning above.

The drum should have a shiny even green in the middle, possibly with a little aluminium metal at the edges and a cog at one end. As already said don't touch the drum with bare fingers as this will leave a greasy mark. however if you brush the surface lightly with tissue a slight black residue of toner may show - the waste removal mechanism is not perfect.

A simple diagnosis is a vertical mark on the page that corresponds to a mark around the OPC. A scratch in the OPC or a defect in the waste scraper blade will leave a corresponding circumferential mark around the drum. If this is an indentation into the surface that is the end of the drum. If it is a raised line of caked toner caused by something like a hair trapped in the scraper blade it might conceivable rub off or disappear with time.

To check for a blotch at 94mm pitch you can rotate the drum. Blotches are typically sticky. How sticky materials get on OPCs is a mystery, as is their persistence despite the attention of the scraper blade. Glue from a label that came off in the print process is certainly a possibility. A lot of people save labels by passing the sheet back and forth through the printer. Label sheets are not intended for use that way and a part-peeled label can be attracted by the static field into the drum.

Stop Test

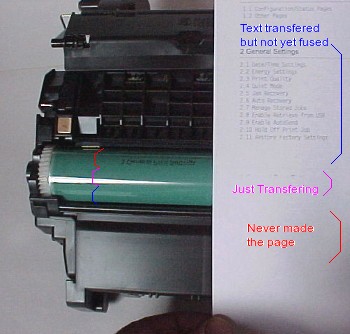

A stop-test is a fairly common way to find out if the printer is making an image on the drum and whether that is transferring to the paper. Set the printer to produce a page with a reasonable amount of information on it, like its Administration Menu Map. Then when it is creating the page open the lid, that will stop the printer dead in it's tracks.

Take the cartridge and the part-printed page out. The page will be partly fused, text will wipe off with a finger.

Open the drum shutter and there will be nearly a quarter turn of the drum where the image is ready to transfer but has not done so, and an angle of a few degrees where it was in the process of transferring. Another segment that should be largely clean where the image transferred from drum to paper, a faint remnant of the image might be visible heading to the wiper blade; if so the transfer roller needs attention.

The drum can be rotated by it's cog. Only push it in the direction it is supposed to move - towards the nose, away from the hopper. If the drum is made to rotate the other way the waste scraper blade could flip and that will not only prove hard to remedy but the elastic repercussion is likely to damage the drum surface. It is actually quite difficult to push the drum round either way; the waste scraper blade puts up a lot of resistance.

A "backgrounding" problem may be evident as excessive residual toner. This could be the cleaning process, charge on the pre-charge or developer roller or the toner itself. The cleaning process in these printers is quite complex, involving a waste scraper blade, a burst of AC and DC on the precharge roller and apparently a discharging scan of the drum by the laser scanner unit. However if one cartridge works but another does not then the fault is probably the waste scraper blade. It would be difficult to blame the precharge roller for backgrounding if the cartridge does actually print. It would always be wise to try cleaning the printer and electrical contacts before condemning a cartridge as faulty. It is possible for one cartridge to seem faulty and another not when the actual problem is printer cleanliness.

Light print is most likely to be charges: - precharge repelling toner to strongly, developer charge or toner triboelectric charge inadequate - and bad drum grounding. It could also be the transfer roller failing to pull toner from the drum adequately. That can be checked by a stop test

.

Horizontal banding at 94mm intervals is also likely to be the drum. Drums are sensitive to light by design and they age with exposure to too much of it. If the drum is left exposed to light it will lose sensitivity and then a band is likely to lack contrast - particularly at the edges where the cover doesn't mate properly and in line with the laser slot.

Cartridges come packed in a light-proof bag and box. If a cartridge is not going to be used for any length of time more than minutes put it back in the bag and a box. If you have disposed of the wrappings then put the cartridge in a black bin-bag inside a box.

Here are a few examples of the sort of faults laser printers can produce - at the moment they link to some generic fault files.

| White Page | Grey Background | Dark Page | Black Page | Skewed Print |

| Creased Page | Curled Page | Rear of Page Mucky | Rear of Duplex Print Shaded | Page Misregistered |

Printer Cleaning

Print quality problems in laser printers are often cause by poor internal cleanliness. A print cartridge has a set of rather unimpressive electrical contacts such as the drum axle and a couple of explicit contact pads that carry the voltages into the cartridge. If these surfaces don't mate cleanly with the springs on the left side of the cartridge well the imaging process can't work properly.

For rather obvious reasons the internal surfaces of laser printers are black; otherwise users would be saying "oh it looks horrible in here". The black innards also help mop up stray rays of light that would damage the cartridge drum.

We might argue the surfaces should be white so that the dirt really shows. The inside of the printer does matter, particularly the electrical contacts but also the cogs, cog-grease and the sliding surfaces that guide the cartridge into its seated position.

The cartridge has to reach the correct position with respect to the transfer roller with considerable precision, which is a moderately difficult bit of design considering it is essentially a big plastic box.

The main collecting point for escaped toner is round the transfer roller in the bottom of the print-cartridge well. Gravity would naturally take toner there. In action the transfer roller is charged to be very attractive to toner on the drum so toner powder will head towards it and the metalwork around.

Paper normally emerges from the top of the printer, unless it is to be "duplexed" in which case it goes through the duplexer, down the back of the printer, underneath and back through the transfer station to have the other side printed.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013.