HP Original Toners

Fuser

Spares

HP P2035 and P2055 Defects Ruler.

Defects Rulers are a very useful diagnostic when laser printers have a fault, often indicating the source of a problem quite quickly.

Laser printers are based on a series of rollers across the page which move electrical charges and then develop the image. Print defects down the page are usually very clearly related to the circumference of the rollers, so if the roller is 3 inches round then damage to it will result in marks down the page at 3 inch intervals.

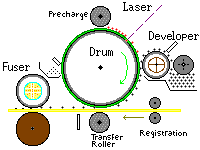

Laser Printer Main Components

Laser printers work by coating a photoconductive drum with an electric charge. The whole width of the drum is pre-charged. A laser scanning back and forth then selectively releases the charge where light strikes leaving a latent image in static charge. The latent image moves past a developer and charged plastic toner powder sticks more or less densely depending on the charge. Further round the powder is stripped off the drum and onto paper by a transfer roller. The paper then passes through a fuser, which heats and presses the paper sufficiently for the toner powder to adhere.

Since the main components of the printer are rollers print defects can often be traced to source using a ruler.

The heart of the laser print process is the photosensitive drum which is part of the print cartridge. It can be seen if you push the shutter on the bottom of the cartridge open for a short time. Be careful not to touch the drum itself, it is normally green or blue-green in colour. The thin plastic coating on the drum carries an electrical charge on its surface. Between the coating and the metal of the drum is a one micron coat of dye which reacts when light hits it by becomming momentarily conductive, allowing the charge above to drain into the metal. In the P2035 / P2055 catridge the drum is in fact 75mm in diameter - 2.95 inches.

One source says the OPC coat used in the CE505A cartridge is thinner than usual and that makes it more fragile and refilling more difficult.

The defects ruler-list given here applies only to the P2035 and P2055 printers (and their Canon near relatives ) - the figures can be very different for any other printer although the principles still hold.

| Roller | Distance | Remark | |

|---|---|---|---|

| Photosensitive drum | 75 mm | (2.95 in) | Heart of the cartridge. Sticky marks can sometimes be cleaned off with damp tissue and/or a dab of isopropyl. |

| Primary charging roller | 38 mm | (1.5 in) | Part of the cartridge, not accessible. |

| Transfer roller | 39 mm | (1.54 in) | Under the cartridge in the printer, easily cleaned or changed |

| Developer roller | 42 mm | (1.65 in) | A fundamental part of the cartridge, not visible or accessible |

| Registration roller | 43 mm | (1.69 in) | Just before the cartridge in the print path, not normally prone to making lasting marks. |

| Fuser film | 57 mm | (2.24 in) | Usually just visible through the fuser entry and exit slots. Will innevitably fail at some point |

| Pressure roller | 63 mm | (2.48 in) | Also visible through the fuser slots. Not normally very prone to lasting damage. |

Damage to the Photosensitive drum can sometimes be spotted by opening the shutter and pushing the drive cog round - they turn very stiffly because of resistance from the cleaning blade inside. Look at it this way, if the cartridge is damaged there is little harm in trying to fix it because otherwise it is definitely waste (keep toner off your clothers or see here.)

Damage to the charge roller or developer will probably be some contaminant getting into the cartridge mecahnism, and is more likely with refills and refurbs - it is very rare with manufacturers original print-cartridges. There is no alternative but to change the cartridge.

The transfer roller is easily changed, it clips in under the cartridge.

Changing the fuser is a bit of a drama with these printers, it requires the side and rear panels to be removed, several plugs and three cogs swapped. This difficulty is one of the penalties of low cost printers.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015, 2016. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.