HP Original Cartridges

Reliable Remanufactured Cartridges

One of the merits of the P4014 against a new printer is the low cost of good re-manufactured cartridges.

At the moment we don't sell in the US, but we hope to soon

Error Message 50.8 for HP P4014, P4015 & P4515 Printers.

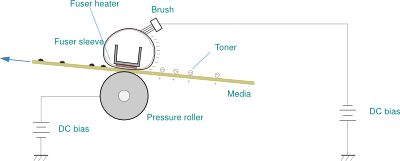

Laser printer fusers adhere toner powder to a page using a combination of heat and pressure. The P4014 series use a thin fuser sleeve as a medium to heat the paper. Error 50.8 suggests one end of the fuser is not heating up which may be damage to the sleeve or heavy media. The fuser may not be to blame.

Other fuser errors are:50.150.250.350.450.550.650.7 50.9

50.8: Fuser Error.

50.8 Lower Fuser Temperature (sub-thermistor). The 50.8 and 50.9 errors are generated by fusers that have a secondary thermistor.

First Steps

As usual with too-cold/too hot errors the first thing to try is turn the printer off, leave it to cool down to room temperature then try again.

Whilst it is cooling down:

- make sure all the air vents have 150mm (6 inch) clearance around them.

- make sure the printer is plugged directly into the mains / line power and not into extensions or a UPS.

It doesn't matter that "it always worked before". Laser printers aren't meant to work on shared extension leads and the fuser operating intermittently creates far too heavy a load for most UPSs. If the error persists you have the option of buying a new fuser (nearly £200 ) or getting an engineer out to find the problem (call-out from £50 to £120 and the price of a fuser too) so save some money: plug the printer into a wall socket and give it plenty of room for airflow.

Details of the Problem

HP don't always make clear why printers have these secondary thermistor error codes; it is a relatively recent innovation in fuser design. However we can infer what is going on and confirm it from patents.

Traditional fusers have two rollers:

- a heated roller which is a hollow metal cylinder coated in teflon with a halogen lamp down the middle.

- a pressure roller which is foam rubber coated with solid heat-resistant rubber with a steel axle down the middle.

Heated and pressure rollers are forced together by springs and driven round by gears. Sometimes the pressure roller contains a heater element as well. Sometimes the spring loading is motorized to suit different media thicknesses. There can be two or three heaters down the center of the top roller to get it to temperature quickly. Making the wall of the heated roller thinner allows it to come to temperature more quickly as well.

Canon and HP dumped this idea because it consumes too much power. In a series of patents from the 1990s the heated roller was replaced by a sleeve of Teflon around a ceramic heater, making the ultimate thin-walled hot roller. The heater is powerful and the sleeve takes very little to heat up so the this fuser is "instant on". It is surprisingly robust as well, Teflon-like materials adhere to one another better than they adhere to aluminium so there is no definite sacrifice in longevity.

There could be a potential issue with control. A hot roller with thick metalwork all comes to roughly the same temperature because of the conductivity and thermal capacity of the metal. The metal of the hot roller conducts heat much better than does the paper media passing through the fuser nip-point. A single thermistor can represent the temperature across the whole upper roller.

Fusers with thin Teflon sleeve or coated foil could develop rather different temperatures across the 220 mm (just over 8.5inch) span across the fuser. This is particularly true if the material being fed through the printer is not a standard size. A single measuring point doesn't represent the distribution of heat across the whole fuser well. This is both a penalty but potentially an advantage of using a fuser sleeve.

When printing envelopes or postcards the fact that the entire fuser width heats up is no help, it just means the edges of the fuser run hotter than necessary overheating the margins of the heater element and the pressure roller. A particular focus of mechanical and thermal stress at the margins creates "edgewear". The pressure roller is a firm but elastic rubber. The ceramic heater bar is far less elastic and reinforced by a strong steel bar. The medium itself has a thickness, in the case of 80gsm paper it is about 0.1mm, and envelope about two or three times that because of the seams. The rotation of the fuser forces the paper in, but it is under considerable pressure at the margins. Mechanically the sleeve and the glass coat on the ceramic heater are under some stress, so is the pressure roller although in it's case the greater stress might be the area at the edges where the fuser is not being cooled by the paper passing through.

European Patent Application EP 0 977 097 A3 by Michael Martin of HP covers Sensing print media size to temperature control a multi-heating element fixing device

.

A fixing device control system controls multiple heating elements included in the fuser so that the duty cycle of the power applied to multiple heating elements results in an optimal temperature profile over the length of the fuser. Multiple thermistors are used in a feedback control circuit to regulate the temperature profile of the fuser

The P4014 printers do know about media size because as well as the size set for the tray they have two sensors at either side just after the registration station.

The actual fuser used in the LaserJet P4014 series is somewhat simplified from the ideal but has two thermistors, one near the middle and one near the margin. It appears that if the margin is too cool it will give "50.8" but more likely it will overheat and give "50.9".

The HP Color LaserJetCP5520 has something like the full implementation of the idea in the patent with two heaters, one for the middle of the page and another doing the edges and four thermistors, one in the middle of the heater, another nearby detecting the temperature of the sleeve and one at either end of the heater.

Web Research

I tried querying Google with P4015 "50.8 FUSER ERROR"

in quotes and got a suggestion of About 13,300 results

; once more implying a popular topic.

- fortwayneprinterrepair I like this site but this is just the index page and not an answer to the query. There is an article about 50.8 amongst the stuff but it is for the P3015 and isn't insightful.

- HP CLJ-2600N another in the collection of irrelevant printers that can have error 50.8.

- fixya wrong printer, wrong advice.

- chirasu.com About Chirasu.com "We capture snapshots of RSS feeds as their contents are udpated" - so that explains why its a miscellany of the semi relevant. Its a sort of search engine. Nothing relevant though.

- scribd Scribd flash version of the HP service manual. Useful enough if you can't find the pdf.

- helpowl right fault, wrong printer, nothing useful.

- thumbcreator collection of pages supposedly related to 50.3

I'm disappointed in this. There were just a couple of pages of scarcely relevant stuff before the repeat the search with the omitted results included

message. Perhaps I need to change my search strategy. I'll give the current method a couple more goes.

HP do themselves no favours. They know why they are fitting sub-thermistors in fusers (or if they don't Canon do) and why they merit a different error. However so far as I can tell they do not explain, either in the service manual of on their web sites.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalogue. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.