HP Original Cartridges

Reliable Remanufactured Cartridges

One of the merits of the P4014 against a new printer is the low cost of good re-manufactured cartridges.

At the moment we don't sell in the US, but we hope to soon

Fuser Errors

Fuser errors usually occur after printing many thousand pages. The printer control panel shows a message like "50.1 FUSER ERROR". In all probability the fuser will need replacing which is expensive. For the LaserJet P4014:

- Just under £200 for a fuser alone

- Somewhat over £200 for a maintenance kit

A new fuser for a machine like the P4014 is more expensive than some new printers. On the other hand those cheap little printers are expensive to run, whilst the P4014 and P4015 have big cartridges that deliver a page for between 0.7p and 1p per page, amongst the industry's lowest. The per page price for little printers tends to be three to five times higher. If you need a lot of printing, you are going to replace the fuser in powerful printers like the P4014 series. The good news is that it is easy to do, you don't need an engineer to do it and if you get a maintenance kit the printer will be good for just under a quarter million more pages.

If you are happy to buy a new fuser or maintenance kit without further reading by all means do so in the catalogue here. However if you hope to save money or just to learn why the fuser might have failed then keep reading.

What Fusers Do

Fusing is the last stage in the laser-printer process. The fuser heats and presses toner powder to make it adhere to the page.

Toner powder is laser printer "ink". Toner is a fine-ground plastic dust with the consistency of cornflower. Toner materials are strongly attracted to static electricity.

The print process focuses around the imaging drum, which is part of the cartridge, together with the toner. The printer charges the drum using static electricity then as it rotates it is selectively discharged using a laser creating a latent image. Next the drum rotates past the developer, which carries a layer of toner. The static fields attract toner powder which is then pulled onto the drum. Further in its rotation toner is pulled off the drum and onto the page by the transfer roller. The fuser softens the toner and sticks it to the page using pressure. More here.

There are many possible designs of fuser but only two are common:

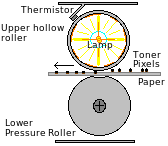

- Traditional fusers use a pair of rollers to heat and compress the page without smearing the toner. The top roller is a rotating aluminium tube coated in Teflon and heated to a couple of hundred degrees centigrade by a halogen lamp running down its middle. The lower roller is usually made of stiff heat resistant rubber material. The roller has a couple of sensors mounted on it, a thermistor senses the temperature and maintains it by turning the lamp on and off every few seconds. The other sensor is a cutout or thermal fuse that will keep the fuser temperature from rising dangerously high. This is a time honoured and widely used design. A disadvantage is that it takes some time to heat the rollers up to working temperature - so if another print job is expected soon it will be kept hot, wasting power.

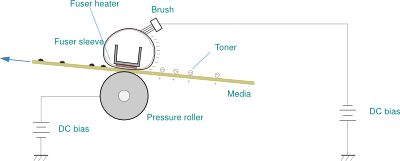

- Instant-On fusers were invented by Canon and HP. The top roller is replaced by a heated ceramic bar but that on it's own would smear the page. To prevent this the bar is loosely wrapped in a Teflon sleeve which rotates with the page. The ceramic heater is powerful, it can turn on and heat the sleeve and the nip-point with the roller in less than ten seconds, so it is only heated to temperature when needed. A typical printer is used intermittently so this can save a significant amount of energy. Almost all HP and many Canon printers use this principle.

Fusers wear out. The Teflon coat on the roller or sleeve gradually loses its non-stick properties and then toner from the page builds up. Heavier page cover like dark pictures or strong black banners stress the fuser sleeve more. The materials fatigue due to the hot-cold and pressure cycles and and break up. The hotter a fuser runs the more it is likely to fail, the heater will be on more, and nearer its limits. Many other materials are near their limits too, like the rubber material of the pressure roller and it's glass or fiber filled plastic bearings. Heavier media like cards and labels will impose extra wear.

Fuser failure is just treated as "one of those things" with some cheap printers and there are no easily replaceable spares. When the fuser wears out it is presumed people will buy a new printer (most could be fixed). Higher cost printers have the fuser as a replaceable module. The P4014/P4015 series fuser is very easily changed; it is a simple plug-in unit. Changing the fuser adds about 0.1p to the price of printing a page and is often forgotten. The price of toner is far higher and costs between 0.7p and 3p per page depending on machine and brand. When people are faced with buying one, fusers can appear expensive but the cost is trivial in the greater scheme.

Fusers wear out just as inevitably as cartridges use toner. A fuser typically lasts about 10 times as long as a large cartridge. With P4014 and M601 series printers the firmware will predict the failure and at 225,000 pages it will prompt the user for a maintenance kit. The supplies status page and the Information > Supplies-Status

page give a bar graph showing when a new kit will be required.

With HP printers, owners are at liberty to ignore the maintenance kit message, there is an option to clear it for a further 10,000 pages and it is possible to set longer intervals. If you do those things then you will wind up with a 50.X message. That probably means the fuser has come to the end of it's life. It is just possible you might be able to continue anyway, the possible remedies are dealt with shortly.

50.X Fuser Errors

Fuser problems are sometimes described as "50.X Errors" because "50" and another digit is what most HP LaserJet printers show on the control panel. Many printers use the same message which might sometimes cause confusion, but across the printer range the fusers and problems they raise are quite similar.

Fusers for the LaserJet P4014/P4015 often last beyond 225.000 pages of print. Whilst that is generally true there isn't a guarantee. Like car tyres, fusers generally last several years; it is possible to wreck them in a few weeks.

Heavy black print, thick paper, envelopes, labels and plastic media are all likely to exact a toll from a fuser increasing the wear and damage and shortening it's life.

Fusers are straightforward at one level -essentially a hot mangle. In detail the process is quite complicated. A ceramic rod with one or two thick-film resistors under a glass film and a non-stick sleeve is violently heated whilst a stream of cold paper at 1 sheet per second is pressed hard against it. The fuser needs careful design so that it cant set fire to the paper (which was a problem in 1960s copiers). The temperature has to be sufficient to make the toner tacky so that it sticks to the page, but not so high that is sticks to the Teflon. It has to achieve this with material ranging from bank-paper to card and transparencies and with toner cover ranging from nothing to sometimes as high as 90%. The printer has to cope with users who have no idea of these complexities telling it to do the wrong thing.

User Guide

For all 50.x errors the HP P4014 series User Guide says in its "Control Panel Messages" chart (p285) :

A fuser error has occurred.

- 1. Turn the product off and then on.

- 2. If the message persists, contact an HP-authorized service or support provider.

The fuser in printers like the P4014 is supposed to be user replaceable but they suggest you to call an outsider; that is disappointing. In some cases the cost of a call-out could make repair uneconomic.

At least in the Service Manual they are a bit more informative.

50.X FUSER ERROR A fuser error has occurred. The values for X are listed below.

- 50.1: Low fuser temperature

- 50.2: Fuser warm-up service

- 50.3: High fuser temperature

- 50.4: Faulty fuser

- 50.5: Inconsistent fuser (verify voltage model)

- 50.6: Open fuser

- 50.7: Pressure release mechanism failure

- 50.8: Lower fuser temperature

- 50.9: High fuser temperature

- 1. Power cycle the product to determine if the error is persistent.

- 2. Verify that the correct fuser model is installed in the product.

- 3. Verify that the correct voltage fuser is installed in the product.

- 4. Verify that the fusing assembly is firmly seated in the product chassis.

- 5. Verify that the connection to connector J82 on the DC controller PCA is firmly seated (P4014 series only).

- 6. Inspect the fusing assembly connectors, at the front of the assembly, and the connectors on the high-voltage power supply PCA. Look for bent pins or debris. Clean or straighten the pins if necessary.

- 7. If the error persists, replace the fusing assembly.

- 8. If the error still persists, replace the high voltage power supply.

Fuser errors need a bit more explanation.

"50.1" is usually clear enough and the end of the fuser. It is just possible that the power-supply or the DC-controller might be to blame but to check that meter the fuser heater elements. "50.5" means you are trying to use the wrong fuser (the 110V device won't work in a 220V machine and RM1-8396 for the M601 apparently will work but will give errors).

The other errors are more questionable, possibly recoverable. They are all capable of disappearing - or of meaning there is something rather worse than a fuser wrong like the power supply board or DC-controller. We'll return to those issues below.

Errors Without Messages

Fusers can go wrong and initially give no error at all.

If the Teflon foil shreds but is still largely intact then non of the printer sensors will detect an error - at least at first. The user will find marks on the page and toner not adhering to the page properly and might find some bits of foil in the output tray.

Less self evidently fusers can give smeared print. Instant-on fusers use a non-stick sleeve around a ceramic bar heater to prevent print smearing as the page touches the heater. The sleeve is lubricated to make sure it turns freely, but it has to do this at high temperature. Lubricants that work well at high temperature are an interesting science. Fuser refurbishers have sometimes got the lubricant wrong. To see if the fuser is causing print problems use astop test.

If the lubricant has settled in an odd pattern it is possible for the fuser sleeve to stick, creating a paper jam. In printers like the P4014 and M601 the fuser has a separate drive motor and cog-chain. In principle the DC controller should notice if the fuser is unable to turn properly and the 59.2 error should be raised; however there is evidence that this doesn't happen so jams are possible.

The fuser also carries one of the paper detection flag and photo-interrupters, so it can give paper feed errors if this fails.

Errors Messages and Speculation

Dealing with computers, fault finding and problem solving is often largely a matter of speculation and inference - quite contrary to the logic and certainties sometimes presumed to dominate.

HP know what their error messages mean; however they don't always make it at all clear in the manuals. In fact, as we note above, it is left totally opaque in the user guide and what the service manual says is just a bit more revealing. There is a bit of evidence that the design teams have some leeway in what faults get which messages and that information might not filter through to the teams working on documentation and customer support.

Research on Internet forums does makes it clear that people often respond to the prompt "50.X FUSER ERROR" by buying a new fuser; its an expensive item and it isn't always the right answer. It is even possible to install a new fuser and have it damaged as well - (its happened to me on one occasion). People who sell fusers don't find much profit in it (HP gets most of the purchase price) so we don't want damaged ones sending back. If HP don't reveal precisely what the messages mean we have to do a bit of research, make some assumptions and try to infer what is going on.

50.1: Low fuser temperature.

50.1 Low Fuser Temperature Error usually means the fuser stayed cold when power was applied. The implication is that is has a damaged heater circuit, and most probably all the heater elements in the fuser itself have blown.

The 50.1 Fuser Error is a low fuser temperature. The fuser heater was given power but the thermistor monitoring circuit showed no warm up. Since thermistors don't often fail the fault is more likely to be the heater. If the fuser is taken out of the printer it is often stone cold - (be careful because if the thermistor did fail then the fuser could be very hot!)

Checking that the heater really has failed needs a multimeter to measure the resistance. There are actually two heater traces on the P4014 fuser (many older fusers have one trace, some now have three). The wires feeding them come out on either side of the fuser and go to two or three of the larger pins.

Web Research

I tried querying Google with P4015 "50.1 FUSER ERROR"

in quotes; this gave About 6,500 results

which is lower than might be expected for the most frequent error, perhaps because technicians are only too familiar with it.

- fortwayneprinterrepair Good introductory article by a working engineer. Not much information going beyond what most of us know. Quite a bit about direct power supply which is will be more relevant on US 120V power. Nothing about the sub-thermistor, pressure adjustment photosensor or about replacing parts. Wrong about there being nothing compatible (M600 and Nupro). No diagram. (OK I'm being picky)

- Precision-Roller YouTube video on installing a mintenance kit in the P4014.

- printerrepairsupport Brief, mentions turning off and on and power source, doesn't discuss any part numbers other than RM1-4554 but no mention of CB506-67901 or RM1-4579. No diagram. Blog with no comments.

- thelaserguys Rather generic page about "50 Service Errors" primarily aimed at the 4200 series so a bit out of date. However they do have a good article on metering suspect fusers

- fixya Rather generic page covering a great many printers in Fixya's usual cheerfully brief (not to say innadequate) style. Typically 1702 people viewed a page 2 people found it helpful.

- helpowl More adverts and offers of miscellaneous irrelevant dowloads.

- fortwayneprinterrepair puffing his article above.

- mindmachine our own article on the P4515 printer.

- depot-america seriously out of date article unless you still have LaserJet 8000 series printers.

- printertechs General laser printer troubleshooting page. Slightly disappointing material because printertechs are often very good.

50.2: Fuser Error.

50.2 Fuser Warm Up Service or fuser warm up timed out. When the printer tried to heat the fuser the temperature measured by the thermistor did not change sufficiently in the time allowed. This problem seems less frequent than "50.1" and a bit less common than it used to be on older printers. It seems that the temperature does change when this fault occurs, just not sufficiently. The fault is a bit more difficult to diagnose because more details of the circuit are involved.

There are actually two heater circuits in the P4014 series fuser (although the circuit diagram shows them "common" at the fuser connector). If either side fails that will leave the fuser able to warm up but not reach the working temperature needed for full-speed operation from cassette 2. "50.2" might not be just like 50.1 but it would spell doom for the fuser.

However it is also possible for the fuser not to reach temperature because the supply voltage is inadequate in some way. Heat falls away rapidly with voltage (square law), so a power brown-out may allow printer electronics and motors to run but be insufficient to get the fuser to temperature.

Printers should be plugged directly into a wall outlet, not into an extension cable and certainly not into a UPS. HP and many other sources stress that low voltage issues can be caused by extension cables. Most buildings were built and wired long before IT equipment became commonplace and extensions are used to provide power for clusters of computers. In the US power is supplied at a nominal 120 volts or so. The heater in a fuser needs about 10 amps of power to reach temperature - which is near the limit of 15 amps can be drawn from a NEMA-5 outlet. The high current can pull the voltage down. This problem is probably more common in the US than in Europe and the UK where the 220 Volt supply voltage means the printer only needs to draw about 5 amps. However the argument still holds - if you have a 50.2 error try plugging the printer directly into the wall.

Readers might be surprised but in our own office we found a 2 volt drop between a wall-socket and the farmost extension with nothing but computers, routers and monitors plugged in - the printer fuser wasn't even operating at the time. (OK some of that could be power factor).

"50.2 error" is a problem because there could be other causes. Operation of the circuit goes along the following lines.

The printer begins it's initial self test and warm-up at power on. According to the Service Manual the printer temperature is measured using the environment sensor thermistor on the fan housing and the DC controller estimates how long the fuser should take to come to temperature. Power for the fuser is actually switched by the power supply board, largely under instruction from the DC controller. The thermistor on the fuser feeds back the current temperature to the DC controller. There are three main things in the feedback loop - fuser, DC-controller and power supply, but the environment sensor has to be taken into account as well.

With some printers a warm up problem might be caused by the environment thermistor. If the printer has been moved from a cold to a hot room (or from a warm place to a cool one) then the environment thermistor will be wrong and the fuser warm-up timing will be out as well.

Look for weird things like material stuck to the sleeve which might stop heat travelling correctly or distort the material so it doesn't sit correctly. A traditional fuser could get material stuck under the thermistor so that the temperature on the roller was too high whilst that on the thermistor was too low. However we don't think that is likely for the P4014 fusers because the thermistor is on the heater bar inside the sleeve.

Diagnosis & Repair

50.2 is quite likely to be fixed by unplugging the printer, leaving it for half an hour so the fuser cools down then trying again. Meanwhile get it plugged directly into the wall. Cycle the printer power a couple of times before concluding that a new fuser is needed. Try metering the heater circuit and thermistor to find out if it is good.

If the problem persists another point to check might be the printer driver fuser setting. The P4014 has four fuser settings (for each media type) the idea being that the user can select the one with best results. It is possible that firmware might be confused by particular mixes of settings, heavy media and unfortunately low voltage.

If 50.2 were to occur whilst printing was in progress that might imply the media is cooling the fuser beyond it's ability to heat up.

Web Research

I tried querying Google with P4015 "50.2 FUSER ERROR"

in quotes; it gave About 70,400 results

, suggesting this is a fairly popular topic.

- fortwayneprinterrepair Brief article specifically about the P4014 series and 50.2 errors

- printerrepairsupport Another article specifically about the P4014 series and 50.2 errors, rather similar to the first.

- HP_forum. Question is relevant but answer just says "get it repaired under warranty", which won't be much help for owners of the P4014 series now.

- spiceworks article about ghosting ultimately cured by swapping a third fuser. I didn't feel the advice was very sound. Should have done a stop test.

- fixya Answer ripped from somewhere else ?

- feedreader.com Nearly useless.

- laserzone123 Boilerplate rubbish trying to sell refurb fusers for $150 with $50 charge if no core exchange. Refers to the P4015 as having an upper fuser roller, it has a sleeve instead.

- printertechs article suggesting that not having the fuser internal connectors onto the heater ceramic pushed home could give the 50.2 error on a range of HP printers. A good suggestion.

- laserprinterhelp General article on the P4015 series

- fortwayneprinterrepair puffing the article that heads this list.

- marketpoint.com Almost nothing beyond cut and paste from the service manual.

- fixyourownprinter forum stuff directly relevant to "50.2" on the LJ-4200 but with some relevance

- mindmachine article I'm working to improve.

50.3: Fuser Error.

50.3 Fuser Error Warm Up Service or Fuser Error High Temperature. The fuser became hotter than expected.

The high temperature problems that give "50.3" might seem the converse of "50.2" low temperature but the two are rather different. Extension leads won't cause high voltage; nor will most possible failure modes in the fuser heater. High temperature could be because of power, ventilation or a failure in the control circuit. A defect in the fuser is possible, but not a certain diagnosis merely on the basis of a 50.3 message.

High fuser temperature could be caused by the electricity supply giving high voltages, and this is more common than generally thought. However, before jumping to the conclusion that the fuser has gone wrong - or the power supply is overwhelming the printer, some other checks will help. Some of these checks are not very easy, but could save time and money.

Overheated Fuser

Signs of an over-hot fuser before an error happens are:

- Creases vertically in the paper. Paper creasing usually happens when the fuser is hot and / or the paper is excessively damp. Paper always contains some water - it is a hygroscopic material and will pick up moisture from the atmosphere even if it could be hermetically sealed in a pack. Very dry paper may not work in a laser printer anyway, the electrostatic transfer characteristics would be odd. Paper comes into the fuser cold and is suddenly hit with blazing heat, it expands and softens as steam is driven off but not at all evenly as it is in the tight grip of the pressure roller. The result can be one or two somewhat irregular creases down the page. Other signs of the same problem is that paper will curl excessively in the ouput tray, sometimes rolling up into a cylinder along its length. Obviously paper in this condition won't pass through a duplexer reliably.

- offsetting is another possibility. The toner is too hot, melts and sticks to the hot surface but the paper does manage to separate from the fuser. Unfortunately the toner does not, travels round and makes echoes or ghosts of the print down the page. This is known as offsetting; the ghost print is at intervals of 94 mm which is the circumference of the fuser sleeve.

- paper wraps into the fuser. The toner gets too hot and tacky, the page cover is too high and the paper fails to separate from the heated surface. It sticks to the hot surface of the sleeve instead and dissapears into the fuser. The printer should go to a 13.xx error as the page never emerges. This can be difficult to spot as the paper wrapped around a fuser looks just like a oddly coloured roller. It is also difficult to fix without dismantling the fuser. Sometimes the trailing edge of the paper going round is visible and it can be gently pulled and peeled away.

These things can happen without the printer actually going to error, although the last problem is very likely to precipitate a "50.3".

Outline of the Works

Laser printers use pulses of high power to heat the fuser. The fuser forces soft plastic toner powder into the surface of a medium such as paper giving a tough, wear resistant finish to a page. To do that the fuser raises the surface of the page momentarily near the melting point of the toner. At the same time a pressure roller drives the toner into the pores of the medium. The toner powder used in the LaserJet P4014 series printers is a mix of polyester and iron oxide specially chosen for its low melting point because that improves energy efficiency. HP say (on the MSDS) that the specific polyester used is a trade secret. A bit more information on toner behaviour is available under the CC364A cartridge heading.

The fuser used in the P4014 series is a design invented by Canon and HP that uses a ceramic bar heater wrapped in a rotatable sleeve of Teflon-like material to prevent smudging. The heater is a strip of ceramic with a pair of thick-film metal and carbon like traces on it acting as heaters. The heaters are quite powerful; in action the printers draw just under a kilowatt of power and almost all of that goes towards fusing. If the heaters were not in contact with the sleeve and continually cooled by a flow of paper we suspect they could light up yellow and burn out. (We haven't tried it because we don't have any heaters to waste on entertainment).

The heater is in not normally in danger of burning out because of a control circuit built around a thermistor on the back of the heater. The thermistor feeds temperature readings to the DC-Controller, a microprocessor responsible for print-engine actions in general. The DC controller is told what temperature to reach by commands from the control panel, or from the formatter (which gets them over the network from the driver in the user's computer). The DC-Controller doesn't actually have the clunky components needed to control power itself, they are on the power supply board. Control of the fuser is therefore spread across the fuser itself, the DC-Controller and the power supply board. In addition there is a thermistor on one of the fans acting as an environmental temperature sensor and this lets the DC controller estimate how much power will be needed to raise the fuser to working temperature.

What Could Go Wrong?

Ventilation is a possible cause of problems. An excessive temperature might suggest a ventilation problem or fan failure. The P4014 series designs use no fewer than four fans, although they aren't all necessarily at full power unless the printer has done a lot of work, (The printers are sometimes criticised as noisy). It is widely suggested that blocking the fan vents on the side of the printer can trigger 50.3 errors.

Ventilation issues are a slight a puzzle. If the fuser innards are becoming too hot why does the DC controller feedback circuit not reduce power until the flow of paper (or air from the four fans) cools it down?

Heavy work might cause overheating. It may be possible to trigger "50.3" by working the printer continually, or on heavy materials like card-stock which require the fuser temperature turned up. Some printers slow down in circumstances where they have been pushed to overheating. We aren't clear that the P4014 series do that although it does slow down for some materials from tray 1. One of the errors in early versions of the firmware was to switch to slow-print jobs from tray 1 when there was a fuser problem. Was this apparent software error actually a feature - that it could print at all with a dud fuser?

The thermistor circuit could fail. Thermistors work in the temperature range they are rated for - which in this case runs quite high. We don't actually know what temperature the core of the fuser operates at, we see other sites giving figures like 350 centigrade but we doubt that and also think it will depend on what point is measured - the actual heater element, the sleeve adjacent to the heater or the paper in the nip-point between heater, sleeve and pressure roller. The heater will be somewhat hotter than the paper passing under it, as it acts as a reservoir. Paper trapped in a fuser discolours but doesn't usually char much. Thermistors do operate hot and they can fail. It is fairly easy to test a thermistor- they are simply resistances that vary with temperature.

Control breakdown is the worst possibility because it could be spread across several positions. The DC controller and environment sensor thermistor could be implicated. The most likely point of failure is on the power-supply board. If so:

- It is going to be difficult to diagnose, the power supply is deep inside the machine and not easy to work on because it deals with mains power and makes the high voltage for the cartridge and transfer rollers. It will be quite difficult to test out of circuit.

- It could be expensive to fix. New "High Voltage Power Supplies" from HP are expensive - although we can probably source "clean working pulls" from decommissioned machines.

- It will be difficult to fix anyway. The board is in a difficult position in the LaserJet P4014 series - half the printer has to be dismantled to exchange it.

Laser printer electronics contain several measures to prevent the heater running out of control, there is a cutout in the fuser's own heater circuit which should give "50.6" if it is triggered. The powers supply board and engine controller together form a safety circuit to shut the fuser down. The need for all this is that the

Rogue mains power seems a likely culprit for "50.3" errors in our opinion. The fuser got too hot more quickly than the DC-controller firmware expected. Despite all the electronics in the printer the fuser is actually a heater connected directly to the mains. If the mains voltage is 10 percent higher than it nominally ought to be then current goes up 10 percent as well and so the power output of the fuser is 21 percent higher than expected (presuming the resistance of the heater doesn't change). That is quite a significant effect.

UPSs are for computers, NOT laser printers. In principle it might sound as though laser printers could benefit from the sort of power regulation provided by a UPS. However that is probably the worst thing to do unless you have the budget for a hefty UPS. In principle the UPS should give a stable output at the printer's design voltage. In practice a P4014 series device is a huge load of about 840 watts average when it is printing and somewhat more when the fuser is operating. It would need a supply rated at 3 kilowatts or more (about 4KVA) to guarantee a good supply to most laser printers. If too much load is placed on a UPS or inverter the frequency, power-factor and voltage will all be out of kilter and the result could be malfunctioning of the fuser control circuits. For instance, power switching semiconductors are generally intended to operate at the zero-volts point of the AC power cycle but if the power factor is bad that is not the zero current point and the switch could be destroyed. If you must have printing protected by a UPS choose an inkjet, most don't have the high power demand of a fuser.

50.3 problems seem likely to be printers being fed too high a voltage or an odd power-factor. Metering power supplies is a bit difficult and could be dangerous, although it only needs a multimeter set for AC volts. Many UPS's will report the line voltage, so a report from one of those near the printer can help. (No, the printer doesn't need plugging into it, the UPS and printer just have to be on the same circuit). Perhaps it is best to look at simpler solutions first.

Diagnosis & Repair

50.3 is quite likely to be fixed by unplugging the printer, leaving it to cool down for half an hour then trying again. DO NOT merely turn the printer off and on again, there is a risk that a second dose of power will push the fuser to the point where the fuser cutout operates or actual damage occurs. Cycle the printer power a couple of times over an hour or so before concluding that a new fuser or any other action is needed.

The LaserJet P4014, P4015 and P4015 have no fewer than four fans to give the machine airflow. Fan failure should raise a "57.xx" error of course, but it probably is possible to have a fan that does turn sufficiently to not give an error. Make sure all the fans are fairly clean and spin freely.

Fans are no use if users block the vents with ledgers, catalogues and other desktop clutter. Allow about 150mm clearance on every side. Printers should really occupy their own table as they shouldn't be too close to users.

If the problem persists another point to check might be the printer driver fuser setting. The P4014 has four fuser settings (for each media type) the idea being that the user can select the one with best results. It is possible that firmware might be confused by particular settings. Most HP printers have the fuser temperature settings in a "PRINT QUALITY" menu under "FUSER MODES" and can set the level to Low, Normal, High1 and High". This printer series (P4014 etc) seems to have Light1, Light 2, Normal and Heavy but that might be firware dependent. Generally a higher setting will work better on heavier media like letterheads and envelopes - at the possible cost of a shorter life for the fuser. If there are frequent 50.3 errors work from the basis of the default settings.

A warm up problem might be caused by the environment thermistor. If the printer has been moved from a cold to a hot room (or from a warm place to a cool one) then the environment thermistor will be wrong and the fuser warm-up timing will be out as well.

Certain combinations of media and settings may be capable of giving the 50.3 error during a print run. The fuser shouldn't be run too hot - it is bad for the pressure roller rubber and the bearings if nothing else so if it does go to error that may be a blessing in disguise.

Somewhere in their list of instructions on the "50.3" error everyone says something along the lines of "remove, inspect and reseat the fuser". There is no harm in it. It is possible that the thermistor contacts were tarnished - and you might find a label or other foreign object stuck around the fuser sleeve preventing it radiating heat properly.

If the fuser sleeve does not rotate properly then if media were to arrive print will smear. However the fuser should be moving and at temperature before the print media arrives so if the film is not carrying heat away presumably the 50.3 error could happen.

Ultimately you may need a multimeter to solve "50.3" problems. First to test the fuser, try metering the heater circuit and thermistor to find out if it is good.

You may need to test the mains power (line voltage). Since exposed meter probes could deliver a fatal electric shock this should be left for an experienced technician if you have the slightest doubt about your own abilities. Another alternative is a plug-in energy meter, which will often display the voltage and many of the better UPSs will give a read-out of current line voltage as well

We cannot definitely say error 50.3 is NOT a bad fuser - but since fusers are expensive it would be wise to eliminate other possibilities first. Multimeters cost about £10 and are handy for anyone with technical interests. Fusers cost about £180 delivered. If you have a "50.3" - check the other things before buying a fuser.

Web Research

I tried querying Google with P4015 "50.3 FUSER ERROR"

in quotes and got About 3,380 results

suggesting some minor interest in the topic.

- printerrepairsupport Brief article, to the point so far as it goes. I'd want to do more checks before concluding a fuser needs replacing on the grounds of a 50.3 error.

- thelaserguys Generic page on "50 Service Errors" I think this site was once good and has been allowed to drift out of date, every printer mentioned on this page is near-obsolete. Even if it were up to date there isn't much information on the topic.

- HP_forums seem to specialise in one-question, one-answer stuff. Not very informative but recommends checking the input voltage readings.

- fixyourownprinter Forum thread right on the point but doesn't arrive at a fix.

- twitter for FW printer repair. No use for my purposes

- fortwayneprinterrepair

- fortwayneprinterrepair puffing his own article

- depot-america For old printers and scraped from the service manual.

- fixya The usual mixed bag of irrelevances with one mention of 50.3 and no solution. If Fixya didn't exist would it prove necessary to reinvent it.

- putangas fortwayneprinterrepair puffing his stuff.

- rhinotek somewhat dated list

Whilst the articles generally covered the same ground I didn't feel they made any headway into how a fuser could get over-temperature without some glitch in the feedback loop allowing it to do that.

--50.4: Faulty Fuser.

50.4 Fuser Error Often said to be "fuser heater wire failure" (about 20 HP service manuals use this phrase). Sometimes however its Fuser drive or power unit error. Check that the fuser is for the right voltage (110V in the US, 220V in Europe Ireland and the UK). However the LJ 4200 manual says "A problem exists with the customer's line voltage."

Some care might be needed with this message. The HP P4014/P4015 service manual merely says:

50.4: Faulty fuser Verify that the fusing assembly is firmly seated in the product chassis. Reseat

It seems that "50.4" can mean rather distinct things in different printers

Web Research

I tried querying Google with P4015 "50.4 FUSER ERROR"

in quotes and got About 1,590 results

; not a popular topic, then, except among the usual crowd of error-code appreciators.

- fixya usual mishmash of printers and error codes with bits of the service manuals scraped and pasted in for enlightenment.

- thelaserguys Rather old page relating to even older printers.

- printertechs General laser printer page that only mentions 50.4 in the context of the CP2025. A strongly recommended site nevertheless.

- helpowl Several forum questions, half of them about the P4015 but no worthwhile answers.

- HP LaserJet 4200 4300 Numerical Error Messages - It does contain an entry for 50.4 that lead to

The problem exists with the customer’s line voltage. ... The line voltage and current source at the printer location might need to be inspected to ensure that it meets the printer’s electrical specifications.

- LJ-5100 LaserJet 5100 Numerical Error Messages - but it doesn't even have 50.4.

- CLJ-4500 I seem to have hit a shoal of HP error pages. Rather unhelpfully this one says "A fusing error occurred that is related to a faulty fuser".

- fortwayneprinterrepair Big index of articles. I couldn't spot a specifically relevant one in this case. Quite useful though.

- printerrepairsupport This short blog item relates to the P3015 and suggests "drive circuit failure"

- titaniumprint offering the Error Codes chart.

- laserzone123 offering the "Solve Problems" bit of the manual.

- printertechsforum offering another index page - some very interesting stuff but in higgledy-piggledy order.

- onsiteprinterservices Nothing much but an advert.

- fixyourownprinter index page for error 50 on old printers. One semi-relevant entry already seen under 50.3.

- fixyourownprinter same again

- thumbcreator Sort of interesting survey of pages on the issue, but full of ads and downloads

I didn't really feel I'd got an answer to what "50.4" actually was, but at this point I got repeat the search with the omitted results included

, so I gave in.

I wouldn't recommend a new fuser for an HP LJ-P4014 series on the basis of any of that. If you have "50.4" on a printer then:

- Do as the manual says and try reseating the fuser.

- Check the connectors on the fuser.

- Meter the fuser power connectors

- Make sure the printer is plugged into a wall-socket, not an extension or UPS

- If non of that proves the problem and you are knowledgeable about electrical matters or have a plug in energy meter, measure the mains power supply.

50.5: Faulty Fuser.

50.5 Inconsistent fuser (verify voltage model)

This is usually a nice clear problem, you just replaced the fuser but have got the wrong one. The only other explanation might be that the connectors aren't mating properly.

HP say:

Verify that the connection to connector J82 on the DC controller PCA is firmly seated.

Inspect the fusing assembly connectors, at the front of the assembly, and the connectors on the high-voltage power supply PCA. Look for bent pins or debris. Clean or straighten the pins if necessary.

This problem was (and remains) notorious with LJ 4200/ 4300/ 4250 / 4350 printers where the fusers look the same but are different in detail. People neglect to get the printer model completely right and order the wrong fuser. Physically the fuser fits, but the printer shuts it down. This opportunity shouldn't exist with the P4014 / P4015/ P4515 range because they all use the same fuser. Unfortunately a new opportunity for confusion has opened up with the M601 / M602 / M603 fuser which apparently does fit in the P4014 but allegedly gives error 50.9. (Yuk)

Web Research

I tried querying Google with P4015 "50.5 FUSER ERROR"

in quotes and got About 31,600 results

; implying a popular topic.

- thelaserguys page seems innordinately popular with Google, it isn't with me because it was never very informative and is out of date. I'm sure it has backlinks, it will once have been best of breed. Sorry, I'm sure your nice people. Just this can't be the best possible information on "50.5".

- depot-america another seriously out of date page. There are probably very few 5SI and CLJ-4500 printers left in service - you cant get the parts.

- printertechs Just the Index page again. Useful site though.

- HP_LJ-5100 Numerical Error Messages again - fine but irrelevant

- HP_forum Brief exchange on the LJ-4250 but making an excellent point. Sometimes a front cover gets changed since 4200 or 4300 front cover will fit. So you can get the right fuser for what you only thought was the right printer.

- backpage.com completely irrelevant - it must be triggered by an ad that used to be on the page.

- backpage.com Just an add.

- socalprinterservices Ad by a US maintenance company using the error codes as an attractor but giving no information

In practice there were just a couple of pages of scarcely relevant stuff before the repeat the search with the omitted results included

message.

Returns Problem

If you have the "50.5" error you have more than one problem. Not just how to get the right fuser but how to persuade the supplier to take back the wrong one.

Parts suppliers like ourselves are well aware of the problem and take care not to get fuser orders wrong - that doesn't mean mistakes never happen, and we will put them right if they do.

Our own experience and that of distributors is that people can be a little careless about what they order. By the time you get that "50.5" error you opened the box and installed the fuser in the wrong printer. The argument that "Marks and Spencers just take things back" isn't helpful, they make a huge margin on clothes and anyway that policy has changed. Now prove that the printer could not have damaged the fuser (mostly, they don't but they could); that you didn't mishandle it and that it is correctly re-packed in an unmarked box. We find people don't like buying spares where they feel someone else has opened the box. Suppliers try to be helpful but these parts aren't hugely profitable to us (they may be to HP) so non of us in the spares community can write things like fusers off.

--50.6: Fuser Error.

50.6 Fuser Error is one of those errors that HP don't seem to have fully standardised. For the HP LaserJet P4014 series the HP Service manuals (all editions) simply say:

50.6: Open fuser

... which isn't helpful. Judging from what similar printers like the LaserJet 4200 etc reported in this case it seems to mean "open circuit" rather than mechanically not shut and the report relates to the heater, not the thermistor or photointerrupters.

However there is an unfortunate mix of printers and errors using this code which obfuscates it's meaning .

50.6 Fuser error Main or sub thermistor bad 50.6 Fuser is defective (drive circuit failure) CLJ 2600N/ 4600 / 4700 CP4005 / 9500 / 5500 open fuser heating circuit between the fuser and low-voltage power supply CLJ 4500 6 fuser heater cutoff CLJ 8500/8550) A heater error has occurred 1 Turn the printer off and on in the fuser. LJ M3027 M3035 The main or sub thermistors are unable to provide temperature feedback to the ECU. The main and sub thermistors monitor the fuser assembly hot-roller temperature and provide feedback to regulate the fusing temperature. 4240/4250/4350 use this error to mean "open circuit".

If you search on the Web things get no better.

Web Research

I tried querying Google with P4015 "50.6 FUSER ERROR"

in quotes and got a suggestion of About 31,600 results

; implying a popular topic.

- fixya provides another irrelevant page of various half-cocked fixes for a cornucopia of unrelated printers I didn't ask about

- printerrepairsupport article about the LJ 4240/4250/4350 where the "50.6" fault definitely means the fuser is open circuit.

- depot-america have a fuser errors page that is really popular according to Google but I can't imagine why because nobody much has these printers any more.

- fortwayneprinterrepair index page (again)

- HP_CLJ_2600N Control Panel Error Messages.

- HP_CLJ-4500 Numbered Error Messages for the Color LaserJet 4500 and 4550 not relevant to the query.

- HP_LJ-2300 Numerical Error Messages. Not relevant to the query but I'm gradually getting a list of these pages.

- desy.de for some reason giving out Partshere's copy of the P3005 troubleshooting guide.

- rhinotek rather old list of error codes in PDF form.

- scribd Flash version of the service manual.

- laserprinterhelp forum seeded from service manuals; not clear which they culled this excerpt from.

- onsiteprinterservices nothing but an advert stuffed with unhelpful text.

- printerrepairsupport using Facebook for promotional links - no worthwile info.

We think "50.6" means the printer was unable to detect current being drawn by the fuser and gives this error rather than the "50.1" error meaning "It stayed cold".

--50.7: Fuser Error.

50.7 Fuser Error generally seems to mean Pressure Release Mechanism Failure

and that is what the service manual says in this case.

These printers have a small innovation compared with the LaserJet 4200, the fuser has a pressure release. This probably has two aims:

- pressure can be set correctly for the media in use

- it is easier to take paper out of the fuser after a paper jam with the fuser still in the machine.

The LaserJet 4200 didn't have this, instead it had a green knurled knob to help get paper out of the fuser. Users tended to be impatient and rip at the sheets instead, which could wreck the sleeve.

The mechanism puts the fuser motor momentarily in reverse engaging a cog which sets the gap on some cams. Previous printers couldn't do this because it would be impossible to reverse a motor that also drove the drum, so this is one good reason for the collection of separate motors used in the P4014 series.

Photosensor PS699 is the fixing pressure release sensor. If the printer attempts to work the pressure release mechanism and this sensor doesn't operate then "50.7" will result. On the LJ-P4014 series printers 50.7 quite probably is the fuser but on some other models it is likely to be other gears. On the LJ-6015 family a split gear in the printer causes the problem.

Web Research

I tried querying Google with P4015 "50.7 FUSER ERROR"

in quotes and got a suggestion of About 13,300 results

; once more implying a popular topic.

- fixya complete nonsense: someone selling an LJ-4200 maintenance kit, Check the power source and printer model (not for this error), Problem with Low Voltage PSU (printer hasn't got one and No Its Not, Initialize the hard disk (eh), and Most likely its a bad fuser (yes, its a fuser error).

- printertechsforum Quite interesting but re a CLJ-4550 so not directly relevant.

- laserprinterhelp this article is only glancingly relevant but it is quite interesting. I'm generally not much in favour of forums and this gives a reason why, it gives some fairly good information but gets little user feedback. < /li>

- helpowl Nothing relevant

- laserink Nice, brief list of error codes but it isn't always right.

- depot-america Not much help. Out of date.

- HP CLJ-4500 Error Messages - says "error occurred that is related to a fuser motor malfunction"

- HP_LJ-2300HP LJ 2300 Printer - Numerical Error Messages. Not relevant but it had 50.7 = Fuser pressure release mechanism failure too.

- laserzone123 giving away a pdf of the "Solve Problems" section from the service manual.

- fortwayneprinterrepair index page (again)

- rhinotek said "service not available" - it was the same old PDF by the look of things

- scribd flash version of the manual - slow, but better than nothing.

Again just a couple of pages of scarcely relevant stuff before the repeat the search with the omitted results included

message. Perhaps I need to change my search strategy. I'll give the current method a couple more goes.

50.7 Fuser errors due to the pressure release mecahnism not operating beg a question. Why did the pressure release try to operate? If it was a paper jam does the printer show a 13.xx error?

--50.8: Fuser Error.

50.8 Lower Fuser Temperature (sub-thermistor). The 50.8 and 50.9 errors are generated by fusers that have a secondary thermistor.

First Steps

As usual with too-cold/too hot errors the first thing to try is turn the printer off, leave it to cool down to room temperature then try again.

Whilst it is cooling down:

- make sure all the air vents have 150mm (6 inch) clearance around them.

- make sure the printer is plugged directly into the mains / line power and not into extensions or a UPS.

It doesn't matter that "it always worked before". Laser printers aren't meant to work on shared extension leads and the fuser operating intermittently creates far too heavy a load for most UPSs. If the error persists you have the option of buying a new fuser (nearly £200 ) or getting an engineer out to find the problem (call-out from £50 to £120 and the price of a fuser too) so save some money: plug the printer into a wall socket and give it plenty of room for airflow.

Details of the Problem

HP don't always make clear why printers have these secondary thermistor error codes; it is a relatively recent innovation in fuser design. However we can infer what is going on and confirm it from patents.

Traditional fusers have two rollers:

- a heated roller which is a hollow metal cylinder coated in teflon with a halogen lamp down the middle.

- a pressure roller which is foam rubber coated with solid heat-resistant rubber with a steel axle down the middle.

Heated and pressure rollers are forced together by springs and driven round by gears. Sometimes the pressure roller contains a heater element as well. Sometimes the spring loading is motorized to suit different media thicknesses. There can be two or three heaters down the center of the top roller to get it to temperature quickly. Making the wall of the heated roller thinner allows it to come to temperature more quickly as well.

Canon and HP dumped this idea because it consumes too much power. In a series of patents from the 1990s the heated roller was replaced by a sleeve of Teflon around a ceramic heater, making the ultimate thin-walled hot roller. The heater is powerful and the sleeve takes very little to heat up so the this fuser is "instant on". It is surprisingly robust as well, Teflon-like materials adhere to one another better than they adhere to aluminium so there is no definite sacrifice in longevity.

There could be a potential issue with control. A hot roller with thick metalwork all comes to roughly the same temperature because of the conductivity and thermal capacity of the metal. The metal of the hot roller conducts heat much better than does the paper media passing through the fuser nip-point. A single thermistor can represent the temperature across the whole upper roller.

Fusers with thin Teflon sleeve or coated foil could develop rather different temperatures across the 220 mm (just over 8.5inch) span across the fuser. This is particularly true if the material being fed through the printer is not a standard size. A single measuring point doesn't represent the distribution of heat across the whole fuser well. This is both a penalty but potentially an advantage of using a fuser sleeve.

When printing envelopes or postcards the fact that the entire fuser width heats up is no help, it just means the edges of the fuser run hotter than necessary overheating the margins of the heater element and the pressure roller. A particular focus of mechanical and thermal stress at the margins creates "edgewear". The pressure roller is a firm but elastic rubber. The ceramic heater bar is far less elastic and reinforced by a strong steel bar. The medium itself has a thickness, in the case of 80gsm paper it is about 0.1mm, and envelope about two or three times that because of the seams. The rotation of the fuser forces the paper in, but it is under considerable pressure at the margins. Mechanically the sleeve and the glass coat on the ceramic heater are under some stress, so is the pressure roller although in it's case the greater stress might be the area at the edges where the fuser is not being cooled by the paper passing through.

European Patent Application EP 0 977 097 A3 by Michael Martin of HP covers Sensing print media size to temperature control a multi-heating element fixing device

.

A fixing device control system controls multiple heating elements included in the fuser so that the duty cycle of the power applied to multiple heating elements results in an optimal temperature profile over the length of the fuser. Multiple thermistors are used in a feedback control circuit to regulate the temperature profile of the fuser

The P4014 printers do know about media size because as well as the size set for the tray they have two sensors at either side just after the registration station.

The actual fuser used in the LaserJet P4014 series is somewhat simplified from the ideal but has two thermistors, one near the middle and one near the margin. It appears that if the margin is too cool it will give "50.8" but more likely it will overheat and give "50.9".

The HP Color LaserJetCP5520 has something like the full implementation of the idea in the patent with two heaters, one for the middle of the page and another doing the edges and four thermistors, one in the middle of the heater, another nearby detecting the temperature of the sleeve and one at either end of the heater.

Web Research

I tried querying Google with P4015 "50.8 FUSER ERROR"

in quotes and got a suggestion of About 13,300 results

; once more implying a popular topic.

- fortwayneprinterrepair I like this site but this is just the index page and not an answer to the query. There is an article about 50.8 amongst the stuff but it is for the P3015 and isn't insightful.

- HP CLJ-2600N another in the collection of irrelevant printers that can have error 50.8.

- fixya wrong printer, wrong advice.

- chirasu.com About Chirasu.com "We capture snapshots of RSS feeds as their contents are udpated" - so that explains why its a miscellany of the semi relevant. Its a sort of search engine. Nothing relevant though.

- scribd Scribd flash version of the HP service manual. Useful enough if you can't find the pdf.

- helpowl right fault, wrong printer, nothing useful.

- thumbcreator collection of pages supposedly related to 50.3

I'm disappointed in this. There were just a couple of pages of scarcely relevant stuff before the repeat the search with the omitted results included

message. Perhaps I need to change my search strategy. I'll give the current method a couple more goes.

HP do themselves no favours. They know why they are fitting sub-thermistors in fusers (or if they don't Canon do) and why they merit a different error. However so far as I can tell they do not explain, either in the service manual of on their web sites.

--50.9: Fuser Error.

50.9 Fuser Error - High Fuser Temperature but from the secondary thermistor.

Secondary thermistors are used to assess the distribution of heat across a sleeve based fuser. Thermal distribution is simple if a fuser uses an aluminium heated roller - the conductivity of the metal will allow one thermal sensor (thermistor) to do the job. The powerful heater and thin sleeve of an "instant-on" fuser behave differently, especially with unusual shaped media are in use. For instance if the printer is working on envelopes or postcards then the edges of the fuser may well get too hot. That is the kind of thing "50.9" seems designed to detect.

Printertechs say this error can be caused by substituting an M600 series fuser (RM1-8395) in the P4014.If that is so HP have reintroduced the issue with the LaserJet 4200 / 4300 / 4250 /4300 where there was an issue with users getting confused about precisely what printer they had, ordering fusers that would physically fit but then getting 50.5 Fuser Error meaning "wrong fuser". Furthermore the P4014 doesn't actually give the right error message. When they devised the P4014 firmware they wouldn't know they were going to introduce a similar series with a wrong fuser that would fit. (Perhaps the M600 series do give 50.5 when you try a P4014 fuser in them).

However if the fuser is not wrong

This is one of those messages that may clear up if the printer is allowed to cool down. Turn the printer off off and leave it for 20 minutes.

Error 50 generally points to the need for a new fuser. For ordering details see above.

Web Research

I tried querying Google with P4015 "50.9 FUSER ERROR"

in quotes and got a suggestion of About 13,300 results

; once more implying a popular topic.

- HP forum Question and answer re 50.9 Fuser Error. The response is from the service manual and says check J82 on the DC controller, then replace the High Voltage PCB. HP persist in calling the board that; it does a lot more than high voltage, including fuser control.

- printertechs article on the M600 fuser causing 50.9 in the P4014 series, mentioned above.

- printertechs with another article on 50.9 errors in the CLJ-3600 series printers. Try powering off and reseating, but don't expect it to print for long without a new fuser.

- helpowl just a generic index - no idea why Google thought it important.

- fixya A couple of vendors simply advising people to buy a new fuser - it may prove the answer but 50.9 is one of those debatable errors so that isn't very helpful.

- fixyourownprinter thread regarding CLJ-3550 getting 50.1 then 50.9 errors possibly due to blowing a triac on the power supply board. This will innevitably sometimes happen to any printer. No real explanation as to why it then goes to 50.9.

- fortwayneprinterrepair

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalogue. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.