HP Original Toners

Maintenance Kit

Fuser Unit

Spares

HP P4014 etc (P4010 Series) Laser Scanner.

The P4014, P4015 and P4515 all use the same laser scanner unit. The number is given in the service manual as RM1-5465 (RM1-5465-000CN) but has been replaced by RM1-7419 (RM1-7419-000CN).

The same laser scanner is used in the M4555 MFP.

A new laser scanner may be needed if the printer gives 51.10 errors - although it might be worth trying to fix the scanner first (see below).

Laser Scanner Principles

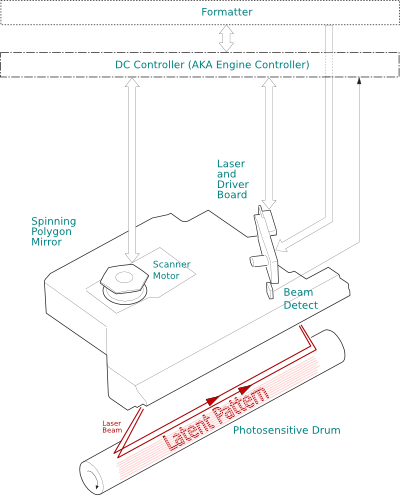

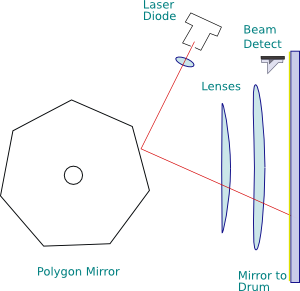

The picture shows how the scanner works. The mechanism contains two principle parts, the:

- laser-drive assembly which contains the laser chip(s) and their feedback electronics.

- polygon mirror - a multifaceted mirror spun rapidly by a motor.

The laser scanner unit also contains several lenses to colimate and re-focus the laser beam. At the end of the assembly a mirror points the beam down at the drum.

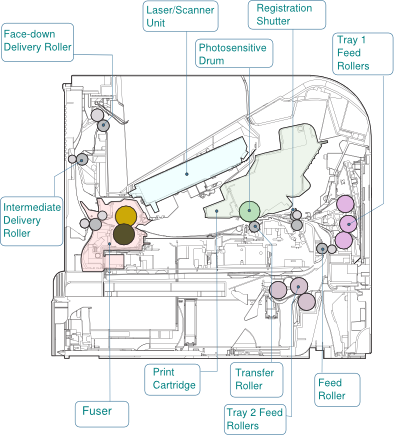

When the machine starts to print, the polygon mirror is set in motion first, by a request to print from the formatter to the enngine controller (or by engine test). The scanner motor can be heard- it makes a thin high pitched whine shortly before printing starts.

Video data for the laser comes direct from the formatter board - it's prime job is to turn the print language into the bitmap in printer memory that will be scanned onto the drum.

The polygon motor speed can be detected by Beam Detect

which comes from an opto-detector at the end of the laser scan travel. The beam detect signal will be regular at a specific frequency when the motor achieves the correct speed. (The motor is a brushless type and probably has it's own hall-effect speed regulation).

Once the laser scanner is at the correct speed the photosensitive drum in the cartridge starts to turn. As the drum turns the laser beam is deflected back and forth by the polygon mirror. At the same time the laser is modulated - turned rapidly on and off - painting a pattern in light. The drum has been electrically charged before it is exposed to light. The light pattern discharges static electricity from the drum. The resulting pattern is static electric fields is called a "latent image".

The drum surface carrying the latent image is turning to face the developer - a cylinder carrying a controlled dose of toner powder. In this case drum charge repels the similarly charged toner, so toner sticks to areas where the laser has painted and the drum is discharged.

The P4014 Series laser scanner is fairly conventional - very like its predecessors for 20 years except in one respect, it is dual beam.

Dual beams are used to create the image more rapidly. The beams sweep the drum creating line 1 and line 3, then 2 and 4 simultaneously. The mechanism for equalising beam strength has several patents; without it the laser strength would drift and create a fine-grained banding in the image.

Reliability

Some laser printer manufacturers are switching away from mechanical laser scanners to LED arrays. The LED array is static so in principle it could be more reliable that the mechanical polygon mirror. In practice the laser scanners used in the P4014 series don't seem to give much difficulty. Of course if you're reading this page you presumably just found differently?

Laser scanner units tend to be rather expensive (Prices over £200).

Refurbished laser scanner units tend to be quite expensive as well. Essentially someone had to scrap a printer to get a laser scanner. (The word "refurbished" is likely to men little more than known good parts pulled from machines scrapped for various reasons. The price of "pulls" may at times be higher than a complete printer on eBay.

Possibility of Repair

There are several points of failure in the laser scanner assembly.

Lasers age, losing something like 50% of their brightness over 20,000 hours operation. However laser diodes can have a feedback signal from a back-facing light sensor that picks up their optical output and feeds it back to the drive circuit, so the drive circuit can keep output stable for some time.

The dual laser system used in this printer poses additional problems because the lasers and their sensors are both temperature sensitive, so it is possible for one to seriously mismatch the other. Patents reveal some of the methods used to achieve balance.

The scanner motor rotates rapidly. The dual laser may cut to half the spinning speed needed from the scanner motor, but it is still rotating at high speed although the manual doesn't say how fast.

Scanner motors can freeze - possibly due to rusting metal fragments in the oil. Diagnosis is often simple, on opening the scanner up the polygon mirror just doesn't spin. A lot of laser printers are restored to working condition by taking off an E-ring,lifting the scanner spindle out, cleaning it up, re-lubricating with a drop of light machine oil and testing it for a couple of hundred pages. Mileage on this repair may vary.

Signs that a scanner motor is failing are jitter in the horizontal position of lines - vertical lines look ragged. This will ultimately be detected by mis-timings in Beam Detect

but that might not be sensed in the early stages.

Lenses get dirty. Some atmospheres where laser printer work are filthy. Laser scanner lenses often get dirty and they can be cleaned. Slightly soapy water followed by plain water is probably best although isopropyl seems to do no harm. (A few plastics break up with Iso, and be careful of mirrored surfaces - the mirroring in optical paths is usually on the outside, exposed surface of the glass).

The laser itself will wear out - as already suggested it will have a half-life or about 20,000 hours. The laser and / or its drive board might be replaceable except that they are probably aligned using factory jigs and infra-red beam detectors. The laser is an infra-red device similar to those used in CD players so it is not inherently expensive. The problem is that devices like this are sourced in quantities of ten-thousand on bandoliers for pick and place machines, nobody is willing to take one off the production line. So far as we know the lasers aren't available.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015, 2016. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.