HP Original Toners

Maintenance Kit

Fuser

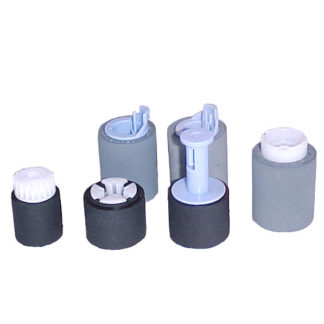

Spares

Paper Jams in P4014, P4015 and P4515 Printers.

These are fairly fast printers. The P4515 gives 60 pages per minute. At the time it was launched this was HP's fastest machine. The P4014 is a speed-limited version of the machine giving 43 pages per minute.

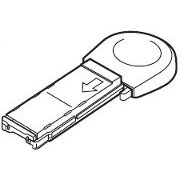

Feeding cut sheet paper is inherently a bit difficult, there is nothing to grip. These printers do the same as most laser and inkjet printers and use soft textured rubber tyres to propel the paper. When the rollers are new this is quite reliable; as they age the texture wears away and the softeners in the rubber are lost - or hard deposits build up depending on the environment the printer is used in.

Pickup rollers generally last 50 to 100 thousand pages, it's difficult to be exact because it does depend on the weight and type of paper used and the use pattern between trays. There is a bit more on this below.

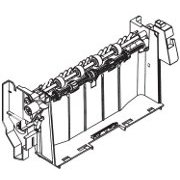

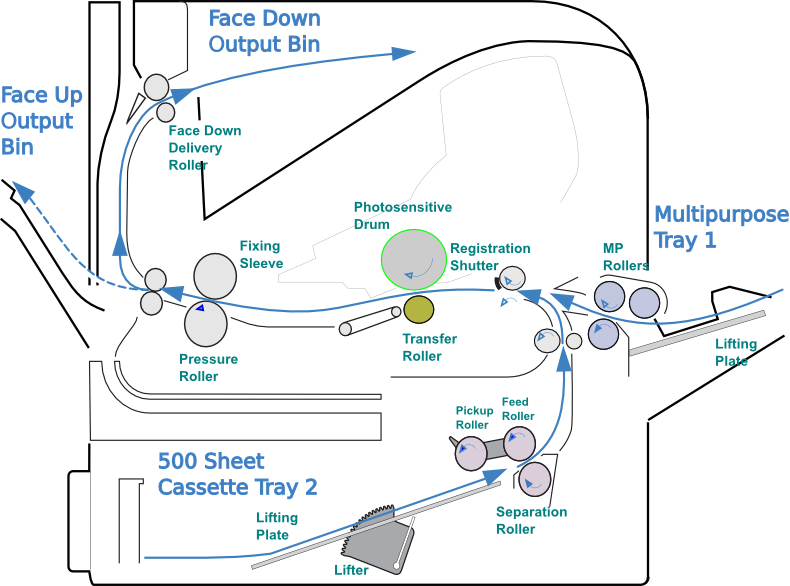

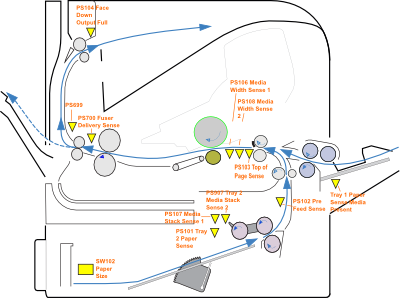

Changing the pickup and feed rollers has been made easy in these printers. Each roller is held onto it's shaft by a latch so they just clip on. The paper path through the machine and the feed roller sets are shown in colour below.

Tray 1

Tray 1 is the drop down multipurpose tray built into all of these printers. The pickup roller is visible at the edge of the tray. One difference between the P4014 and the older 4250 / 4350 printers is use of a triple roller set instead of a roller and pad.

Some people rarely use tray 1, others use it for letterhead paper or envelopes all the time. It can take light card, particularly if the straight-through path to the face-up output bin is used.

Tray 2

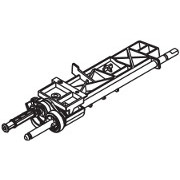

Tray 2 is the paper cassette built in under the printer. The pickup and feed rollers are in the top middle of the printer chassis and visible when the tray is removed. The separation roller is in the front of the tray.

Tray 2 is a cassette neatly pushed under the printer body. Tray 2 will hold about 500 sheets of 80gsm office paper so a whole ream of paper can be loaded. Large paper capacities are useful in office work because having to re-load the paper tray is a disruption.

Feed Repair Kit

Both sets of rollers are available as a single kit. ![]()

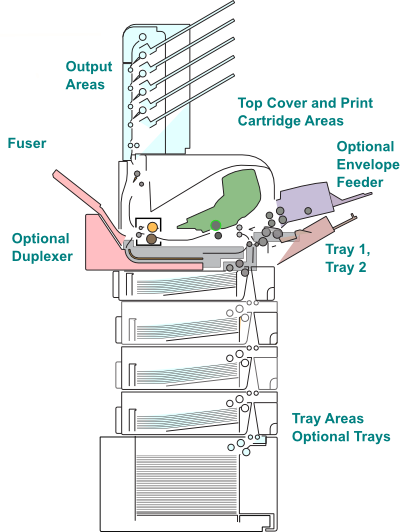

Multiple Trays

Any other trays are mounted under the printer as shown on the right. The printer can take up to four external trays including one 1500 sheet drawer. In its maximum configuration it will normally be placed on a trolley for stability and convenience.

The additional trays all take the same feed roller kit as tray 2.

Paper Feed Errors

Paper feed errors are generally one of three things:

- Inappropriate or badly conditioned paper. Try the paper path with ordinary A4 80gsm office copy paper. Try the straight-through path from Tray 1 to the face-up tray on the rear.

- An obstruction. Try a different paper path. Take the cartridge out and look closely at the paper path. If the problem is not visible there try taking the fuser out (it clips into the rear). Obstructions are quite common on machines used for labels and envelopes because the media is heavy, gets jammed and then part peels away and prevents paper travelling past.

- Worn pickup and feed rollers. The rollers need to be soft and textured to move paper reliably. Once the rollers start to lose their texture misfeeds will increase. When misfeeds do occur that tends to increase wear on the rollers so it becomes and increasing problem. Replace the rollers.

- Possibly, incorrect computer settings. If you tell the printer the media is ordinary office paper when it is actually card it may not use the correct motor power, timing and fuser temperature. These printers attempt to pick up the paper size by switch settings activated by the tray but the mechanism can sometimes be troublesome.

Paper Feed Error Codes

13.01.00 Jam in Tray 1 : The Tray 1 pickup roller or solenoid might not be working correctly. Any obstruction is likely to be visible with the cartridge out.

13.03.00 Jam in Tray 2 : The Tray 2 pickup rollers or solenoid might not be working correctly. The paper path might have an obstruction, remove the cassette and look up the paper path.

13.03.00 JAM IN TRAY X : A jam has occurred in the specified tray. This jam occurs when the printer cannot move paper from the specified tray into the paper path. Suspect the pickup roller - does it have adequate surface texture? Try changing the rollers. If you have more than one cassette try swapping the roller set around.

13.20.00 JAM INSIDE <LOCATION> : Paper has not moved past a certain paper sensor. <LOCATION> can be one of the following locations.

- Tray 2

- Top Cover

- Rear Door

- Duplexer

13.JJ.NT DEVICE WARNING The external device sent a warning.

13.JJ.NT JAM IN <LOCATION> A jam has occurred in the specified location.

13.JJ.NT JAM INSIDE <LOCATION> A jam has occurred in the specified location.

13.JJ.NT PAPER JAM OPEN INPUT TRAYS A jam has occurred in an input tray. Alternates with Open all trays.

Paper Feed Problems

The material above should be a help with most problems, try different paper, different paper paths, double-check the computer settings and when nothing else is wrong - or if the rollers look worn, then replace them.

If there is still a problem then one possibility is a sensor error. These printers have about 10 sensors monitoring the progress of a page through the machine. When a page is told to move the print-engine controller monitors for the appropriate sensors moving within a short time; if they don't respond in a given time then the appropriate paper-jam message is given and the machine stops. Sensor Locations are shown in the illusration.

The printer has a diagnostic mode where each individual sensor can be tested, usually by pushing a piece of card into the paper path and observing the change on the printer's LCD display. It is also possible to operate the motors in diagnostic mode.

Paper Feed Roller Life

In the P41014 series we would expect the pickup and feed rollers to last somewhat longer than usual.

Rollers are driven by their own motor so their may also be an acceleration pattern to reduce roller wear.

The printer has a 500 sheet tray 2 with a lifter as well, so this might help reduce roller wear.

Most significantly these printers use a triple roller mechanism to feed paper rather than the roller and pad used in cheaper machines. Rollers with pads get some serious wear when there is a misfeed. These printers should rarely misfeed whilst the rollers are in good condition.

HP has a fairly comprehensive page on clearing simple jams here.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015, 2016. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.