HP Original Toners

Fuser

Spares

Cleaning HP LaserJet Pro P1102, M1130 and M1210 Series Printers

The HP LaserJet ProfessionalP1102 , M1130 andM1210 Series Multifunction Printers are A4 mono laser printer / copier / scanner aimed at individuals and small offices. They are relatively easy to look after. This page gives some hints on cleaning drawn from the User and Service manuals and experience with printers.

Self Cleaning

These printers are able to clean lose toner and other dust from the paper path to some extent by putting a strong electric charge on media.

Use a transparency for best results. Alternatively use ordinary copier paper with a smooth surface.

Make sure the Ready

light is on

Cleaning pages are sent from the printer driver under the Device Settings

(Windows) or Driver

(Mac) tab. The HPLIP drivers should provide the cleaning ability in Linux ? .Network models may have an entry for cleaning in the web-server pages ?

The cleaning process takes about two minutes. It puts various static charges onto the media as it passes through to pull toner from places it should not have accumulated. It may take several attempts to get rid of marks.

If electronic self-cleaning fails the user might need to to take some action themselves.

Manual Cleaning

If toner deposits are too heavy the printer may need manual cleaning.

Take the cartridge out and place it in a dark place - in the shipment box if you still have it or under a sheet of paper.

Turn the printer off and unplug it. The safety interlock should prevent the high-voltage circuits or laser operating but its better to be safe than sorry.

Use a toner-rated vacuum cleaner if one is available. Although they are quite expensive they are a worthwhile investment if you frequently work on printers.

Do not use an ordinary vacuum cleaner as fine toner particles will pass through the mesh of the filter bag covering things in fine black dust. Printer manufacturers generally don't regard toner as a health hazard and there are some extracts from the MSDS (COHSS) sheet below but exposure can't be regarded as a good thing.

Otherwise use a dry lint-free cloth and possibly a soft paintbrush.

It is possible to use a cloth dampened with isopropyl alcohol or water, however the printer must be thoroughly dry before it is used again. Isopropyl tends to break up toner a bit so sometimes it works better, and it evaporates thoroughly and quickly. Do not use household cleaners that contain ammonia as vapour given off by the cleaner may damage the photoconductive drum.

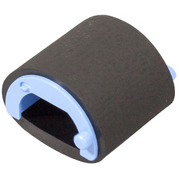

Toner build-up tends to focus around the the black foam transfer roller located in the print-path behind the cartridge and on the roller itself. The roller can be lifted out with some effort - although it is easier with the printer partly dismantled and most people will want to avoid that. Avoid handling the roller itself as grease marks from fingers can give problems, try to touch the cog and shafts.

Cleaning the Roller and Pad

If the printer has problems feeding paper - erratically picks up or attempts to feed two or more sheets and jams - then try removing and cleaning. Have a look at the section on changing the parts.

Cleaning the Scanner

The scanner glass and the white plastic backing can be cleaned with a damp cloth. A glass cleaner can be used but it must be non abrasive and must not contain acetone, benzene, ammonia, ethyl aclohol or carbon tetrachloride. These may damage the plastic components and markings of the scanner.

Need For Cleaning

Cleaning the print-path is a common solution for print quality problems, fading or darkening of pages at the edges, lack of contrast and suchlike. The reason is that what are commonly called "laser printers" mainly use electrostatics to do their work. Essentially its a miniature version of the mechanism used in an old photocopier and the laser just creates the "latent image" on the drum - the rest of the process relies on electrical fields.

Dirty contacts will mean parts of the cartridge don't get an electrical charge. Stray toner and other dust on surfaces can also be a nuisance because charges drain away through it.

Laser printers colour the page using toner rather than ink. Toner is a fine powder made from low melting point plastic - in this case 45% each styrene-acrylate copolymer, ferrite and 10% Wax. At the end of the print process the fuser mechanism adheres the low melting point toner powder to the page using a combination of heat and pressure.

Powder particles are very small, about 5 microns across, so individual dots can only be resolved by a microscope. One reason the toner in recent laser printers is so fine is that it is moved from developer to drum and then from drum to paper by electrostatic charge. Its a technological application of the same mechanism that makes household dust collect on some TV screens. Electrostatic charges have more influence on small objects.

Small toner particles give a sharper outline to print and also allow a measure of grey-scale - photographs and drawing look better. Photographs aren't usually a priority with a mono laser printer like this, but the fine powder allows these machines to provide something acceptable.

Fine particles move at lower voltages and that minimises the printer's tendency to produce ozone.

One problem with toner powder is that it is potentially very messy - as is liquid ink. Print manufacturers invented cartridges as a way to minimise the problem of handling toner. Fine grained toners could create extra problems because they so easily become airborne. the design of the cartridge minimises the problem.

Modern toner is not regarded as a health hazard in the quantities and circumstances users are likely to be exposed to it. The following points are from the CE285A Print Cartridge Material Safety Data Sheet (MSDS).

Skin contact: Unlikely to cause skin irritation.

Eye contact: May cause transient slight irritation.

Inhalation: Minimal respiratory tract irritation may occur with exposure to large amounts of toner dust. Use of this product as intended does not result in inhalation of excessive amounts of dust.

Ingestion: Low acute toxicity. Ingestion is a minor route of entry for intended use of this product.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015, 2016. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.