Feed Separation Roller

HP Original Cartridges

(The "X" size won't fit the M601)

Reliable Remanufactured Cartridges

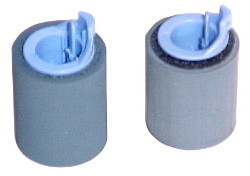

HP RM1-0037 Feed and Separation Roller.

RM1-0037 serves as both the feed and separation roller in a range of HP printers. A very similar if not identical roller can alternatively be called Q7829-67925 (see below). These rollers are used in LaserJets 4200 4300 4240, 4250, 4350 and M4345, M4349, M4555;P4010 series - P4014, P4015, P4515;The Enterprise 600 printers M601 M602 M603,and the A3 LaserJet 5200 .Unusually the same roller set is used in some colour printers; the 4700/4730, CM4730MFP, CP4005, CP4025/CP4525, CM4540 and CP6015/CM6030/CM6040/CM6049 . In the CP3525 they are only used for accessory tray 3 etc. Of course, they are also used in several 500 sheet and 1500 sheet accessory trays as well.

In most cases the matching pickup roller is the RM1-0036 - but not invariably. The CM4540 and CP3525 use RL1-2099 as a pickup roller.

The RM1-0037 roller is grey textured hard rubber on a foam backing. A blue bobbin is used - the colour makes it distinct from the RM1-0036 which has a white core.

These rollers are supplied in significant numbers in maintenance kits such as CB389A. There is a market for rollers beyond those included in the kits because these printers get heavy use and new rollers commonly solve feed problems. Every service engineer who touches HP printers needs at least a couple of RM1-0037 rollers in their kit of parts. People looking to self-repair can buy the feed kits such as CB506-67904 or equivalent, which have a set of the three rollers

Operation

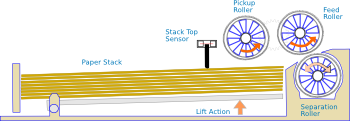

Arrangement of rollers for the RM1-0037 / Q7829-67925. The pickup roller RM1-0036 pushes paper forward. The feed roller tries to drive it out of the tray whilst the weakly driven separation roller would push it back - if it wasn't overcome by the feed roller.

These rollers are used in pairs. The feed roller is hanging down into the cassette draw space from a pickup shaft. The rollers textured surface is soft and flexible enough to establish good contact with a sheet of paper and feed it out of the tray. The matching separation roller is in the cassette tray where it is driven by the retard shaft cog on the front right side of the cassette. This separation roller turns so that it would feed paper back into the tray, except that it's power is weakened by a torque limiter RC2-5771 or equivalent.Sheets of paper are pushed forward by the pickup roller RM1-0036 (or whatever) and arrive at the roller pair which are rotating (The pickup shaft driving the top roller carries an idle cog to drive RM1-0037). If one sheet of paper arrives at the feed/separation roller pair the upper roller will be more powerful and feeds that sheet forward. If two sheets arrive the upper roller is still more powerful but the lower roller is trying to push the other way, the second sheet breaks away from the first and is pushed back into the tray. The roller pair normally give a reliable way of getting one sheet of paper and no more into the rest of the printer process. There is more on the paper feed process here.

RM1-0037 style feed rollers. That on the left is fresh from the pack. On the right is a worn one showing a rather shiny surface and uneven ridges of wear. The roller here (black padding)had probably done 86,000 pages and was still functioning well with ordinary office paper. Heavy, glossy media like labels would give trouble.

Faults and Replacements

If you are reading this then presumably paper feed on one of your printers isn't working reliably. Paper jam problems can have a gradual onset, one day paper will jam in the cassette, in the printers throat or fail to feed at all. The printer will give a message along the lines of 13.xx.yy. Jam

. With a bit of fiddling around, straightening the paper or perhaps unloading the tray a bit the printer will work reasonably again. After that the problem will worsen, usually over weeks rather than days but that obviously depends on how the printer is used. Printers that use these rollers maintain an error log that can be printed or viewed through the printer's internal web server. Paper feed faults caused by rollers will often be rather worse when a tray is full or empty - the pressures on the roller are at the limits of their operation. It is normal to replace both rollers as wear on one implies the other is also wearing out.

Check the roller surfaces. This can be done in position, but they can easily be removed by simply un-clipping them. Don't handle the rubber unnecessarily as it can denature with oils from skin. Old rollers are suspect anyway so this is less of a concern. If misfeeds tend to involve more than one sheet getting caught in the printer then that implies a problem with separation (cassette roller). If the paper doesn't make it to the registration station that implies the feed roller isn't delivering enough traction because it is worn. Either way it is still normal to replace both rollers, and possibly the RM1-0036 pickup roller as well.

It is possible to have a paper pickup and feed fault with a sudden onset. Normally we'd expect that to be something caught in the throat of the printer - it is quite difficult to see round the feed path towards the registration station. It is also possible to damage the retard drive shaft RL1-1658 and the RC2-5262 torque limiter could be to blame, as could the RM1-4532 and the RL1-1657 main motor or RM1-4527 feed rollers in the body of the printer. The opto-detectors associated with RM1-4562 paper feed shaft could be to blame as could the lifter drive RM1-4585.To discover which is to blame try the paper feed problems page.

If the rollers are dusty try taking them out and cleaning them with a dry cloth, first and if that doesn't seem effective try a damp cloth or even cleaning the rollers in soapy water; that will often extract a bit more work from them. Some people like platen cleaner on these although we think the rubber isn't appropriate for it. There are suggestions that isopropyl alcohol (IPA) will denature the rubber by dissolving the softeners.

The feed roller in the printer sits just forward of pickup roller RM1-0036. We sell kits that have the three parts in them - CB506-67904 for instance. It is only strictly necessary to change the two RM1-0037 feed/separation rollers, the pickup roller should last considerably longer than them. When the pickup roller is failing paper won't move forward sufficiently to start down the feed path. We think most people just change all three rollers.

HP Information

HP Partsurfer gives the following information (In July 2013)

RM1-0037-020CN - Part RM1-0037-020CN is no longer supplied. Please order the replacement, Q7829-67925

Q7829-67925 - Feed roller high capacity input (HCI) - Transmit the paper from the cassette and feeds it to the device entrance (blue)

HWP-RM1-0037-000CN Roller -Paper Feed

HWP-RM1-0037-020CN PAPER FEED ROLLER ASS'Y

RM1-0037-000CN Roller -Paper Feed

RM1-0037-020CN Paper feed/separation roller assembly - Gray rubber roller on a blue plastic cylinder

RM1-0037-BULK ROLLER PAPER FEED - MIN/MULT= 36 PALLET= 576

RM1-0037BK Roller, Paper Feed

RM1-0037BUKRU BULK ROLLER PAPER FEED

RM1-0037BULKM BULK ROLLER PAPER FEED

RM1-0037BULKRU BULK ROLLER PAPER FEED

One oddity is HP's preferred code of Q7829-67925 is not completely reflected in UK distribution. The distributors seem mainly to sell RM1-0037-020CN which would be a Canon-made part and would be the second or third version of it. HP might have decided on their own formulation or supply chain but the channel prefers the old part. It generally looks as though RM1-0037, RM1-0037-000, RM1-0037-000CN or RM1-0037-020CN and the HP code Q7829-67925 will get you the same thing. That might not be what HP intend (see below).

RM1-0037-000CN is EAN 5704327504993.

RM1-0037-020CN is EAN 5705965638651.

Q7829-67925 is EAN 5704327631699

Partsurfer information suggests these come in multiples of just 36 on pallets of 576 - its a miniature pallet then ? The RM1-0036 seems to come in multiples of 600, 36000 to a pallet. (Partsurfer is notorious for idiosyncrasies - whenit works at all).

Changes in packaging are one of those things that throw doubt on the authenticity of parts. HP / Canon have never badged individual small parts, presumably feeling that it wasn't worth it. The packaging did shift from boxes to bags a couple of years ago.

Ordinarily, substantive differences between Canon and HP parts has seemed unlikely, however in the case of the RM1-0037 /Q7829-67925 there does seem to be one.

Canon and HP have a long history of cooperating on laser printer design dating back to HP's 2680 Laser Printing System developed from the late 1970s onwards. Canon was then a camera and copier maker; HP an instrument maker with nice lines in scientific instruments, pen plotters and minicomputers so cooperation made sense. The real take-off product in public consciousness was the "LaserJet" launched in 1984 - its arrival brought the end of typewriters. It was based on a Canon engine - as was Apple's LaserWriter.

Most HP laser printers have been based on Canon engines with HP electronics and software, so they share some parts but not all. Very often there is a Canon equivalent to an HP printer - although HP have remained the bigger brand. Manufacturing relationships are often complex - a great many things are made on contract and that doesn't necessarily detract from the work brands like HP and Apple do.

HP's big mono office printers sometimes have no known Canon equivalent. Experience with parts suggests connection. The LaserJet 4200 / 4250 / P4014 / M601 and M604 clearly grew out of the Canon LBP-1760/ HP LJ-4100 engine. HP LJ-4200 machines used an RM1-0036 and and two RM1-0037 rollers. Then with the P4014 the rollers looked roughly the same, the service manuals say they are the same and so people assumed they remained so.

Actually they seem different but HP are giving out contradictory information in the service manuals. If they intended to produce their own rollers they also priced themselves out of the market by setting prices for Q7829-67925 rather high and not making any difference clear. So this part is largely unknown.

RM1-0037 / Q7829-67925 Schism?

The Canon and HP part are different; however although the change seems to have happend several years ago it is scarcely reflected on the Web in June 2015. The only note we have come across is by US part specialist LPT.

Canon-made parts come with the number RM1-0037-020, suggesting they are the third variant of the part (numbers normally go -000, -010, -020). The roller has a grey outer and a blue core, separated by a grey foam fill. The complete roller weighs 9 grammes. We have found no evidence of what changes were reflected by the part number change. HP seem to add the suffix "CN" to things made by Canon and in July 2013 their "PartSurfer" site was still listing the old part as shown above. The LaserJet P4014 service manual says Paper feed roller RM1-0037-020CN

, as does the M601 service manual. However in July 2013 HP PartSurfer was suggesting Q7829-67925 instead, as shown above and now it no longer seems to list RM1-0037.

Parts sourced with the Q7829-67925 code and those fitted to the P4014 and later printers are noticeably different. The roller still has a blue core although it has injection and ejector points in different places and seems a fractionally cruder moulding with a join near the handle and a bulge around the middle which could be deliberate. The big difference is that it no longer has a foam core but a solid black material that is clearly a different composition and seems to be a different moulding from the grey outer - the two can be parted and put back together. The result weighs 12 grammes.

The Q7829-67925 is generally listed by distributors as "FeedRoller High Capacity Input" or something similar. That would suggest it is a better roller. However the service manual for the M601 series lists RM1-0037-020CN as the roller for the high capacity feeder.

The grey outer of both rollers seems comparable and is likely to be EPDM (ethylene propylene diene monomer -also used for rubber roofs and car door seals). This forms the working surface, which would normally be the main point of interest. The inner core of both types of roller is maleable, the foam version seems to be intergral with the EPDM outer and since foamed EPDM is widely used in things like car doors that is probably the composition. The black solid core of the HP roller may be silicone / polydimethyl siloxane (PDMS).

So is the HP Q7829-67925 a better roller than the Canon RM1-0037-020? The soft rubber covering seems the same; however there are patents for pickup rollers containing a mix of small beads of material to improve wear properties - these wouldn't be noticed. It may be the black rubber that makes a difference. At the speed the roller operates there will be very different acoustic wave propagations through the foam Canon and solid HP materials. There seems to be no actual evidence that the new roller wears better or convincing reason to think it would. It might be as simple as HP not liking Canon's pricing or wanting a second source. HP might want to "own their spares channel".

HP and Canon both have patents, even on obscure things like paper feed, but they have generally seemed to pool them. Canon and HP parts are likely to be functionally equivalent unless it is very clear that they are persuing different goals. In mid July 2015 we found no evidence of this. Putting the two codes into Google finds loads of vendors who believe they are the same thing, no policy information.

Curiously, HP also changed the appearance and build of the associated pickup roller RM1-0036. It too has the black core but there doesn't seem to be any new part number for this. There is a Q7829-67924 but it is equivalent to HCI Pickup RL1-1206-000CN - which is used as a pickup roller instead of RM1-0036 in more recent machines but is a different size and shape so not related. Mysterious signals!

The list of printers these rollers fit was given in the introductory paragraph. Some of them are known Canon engines, so they clearly have a right to produce the part.

Clones confuse the issue further. RM1-0037 is a popular and superficially simple part: a plastic bobbin with a commonplace rubber tyre. The price they are sold for reflects Canon / HP and distribution logistics rather than manufacturing costs. This attracts clone part makers Several clone part makers can be found on aliexpress etc sometimes with prices under £1. Experience of such parts has not been good - a close look suggests the moulds were not made from engineering diagrams but from using a part to make a mould. Dimensions are wrong; also they have to guess at the materials. HP and Canon will not tell them - if indeed they tell one another!

Supply Situation

The primary part number RM1-0037-000CN suggests this part originated with Canon and is still made by them. HP then defined their own part Q7829-67925. Canon are still making it even if HP have alternate sources of supply.

One UK distributor also has "compatible" rollers made by 2-Power. Several Chinese manufacturers promise the same thing. Compatible parts are sometimes essential - to keep old LaserJet 4 printers going for instance. In this case compatible parts are somewhat cheaper but we don't currently offer them in the catalogue. We use HP/Canon originals as it raises fewer issues. (If you want to try a batch of the clone rollers we can supply them, of course). As to which is truly the original between Canon and HP we are not yet able to say- perhaps someone will enlighten us.

It is will be cheapest and easiest to buy these rollers in kits unless you want them in bulk (they are widely used). Prices per roller in one-off quantity are about £5.50 (in July 2013) - but this fell to £4.80 in June 2015 as sources of supply shifted. These are guidelines, our prices change with distribution lists - see the catalog .

Stock numbers indicate considerable demand for this part. The largest quantity seen in distribution was 3,488 with several others having stock of over 1,000 items.

We carry local stock of these parts. They are available in small quantity with the lower postal rather than courier charge.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site useage patterns.