HP Original Cartridges

(The "X" size won't fit the M601)

Reliable Remanufactured Cartridges

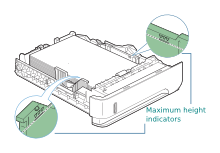

HP RM1-4559 500 sheet cassette.

RM1-4559 is the 500 sheet cassette for quite a number of HP laser printers, namely the LaserJets P4014,P4015,P4515The Enterprise 600 printers M601 M602 M603.

HP normally takes the opportunity to redesign things like trays with each new iteration of a printer, incorporating design changes suggested from field experience, but they didn't in this case. Furthermore the RM1-0037 feed/separation roller is just about the nearest HP / Canon have come to a universal pickup roller. (What next? A Universal Tray? That would simplify logistics).

The cassette will certainly have to be redesigned for the M604 series printers but differences are mainly cosmetic - the fascia is squarer and doesn't have the black stripe. In fact the RM1-4559 is very like the older cassette from an LJ-4200 which was RM1-1088; the main differences being a couple of glide wheels added and the standard/custom knob taken away (custom paper is now an option).

Tray Or Cassette

Most people call this a tray

, however officially it is a cassette

. Other phrases for the object are cassette drawer

or just paper drawer

. The word cassette is helpful because Multipurpose (MP) tray 1 that folds down on the front of the printer can't easily be described that way. People are sometimes confused that the cassette is "tray-2" because they did not realise the MultiPurpose (MP or "tray-1") tray exists and buy the wrong thing (HP try to help, embossing the numbers "1" and "2" in the black plastic).

In principle there is a use for extra cassettes, they can be kept near the printer, pre-loaded with paper ready to be used. This seems to have been the original intention of the design.

Printers can also be expanded with 500-sheet Tray 3 underneath the printer itself. This is probably a better way to expand the paper capacity as things are automatic, but a stack of trays is quite expensive.

Spare Parts

Another main use for the cassette is as a spare; they do get broken. The body of the tray is quite substantially made of ABS plastic. With paper in, the tray weighs over 2.5 kilos and if that gets dropped on the floor it does a bit of damage. People may also be a bit rough pushing things back into place, particularly when they have overfilled it. The cassette looks robustly built (but designers don't take into account the irritation printers often inspire).

The RM1-4559 cassette is compatible with those in the printer's CB518A optional feeder unit. They look the same, use the same rollers and work (but we haven't found anything official from HP).

Component parts for the cassette are not common in UK distribution - so if you break one that may mean buying a complete new cassette - but see below.

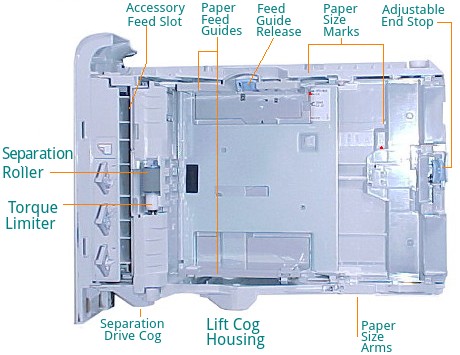

HP_RM1-4559_operation

The RM1-4559 cassette is much like many others in this class of printer, with adjustable sides and end-stop to fit a variety of paper sizes. Paper misfeeds are commonly caused by not setting the guides correctly - there are helpful little pointers moulded into the plastic. It might have been a good idea if HP had highlighted the pointers with red paint.

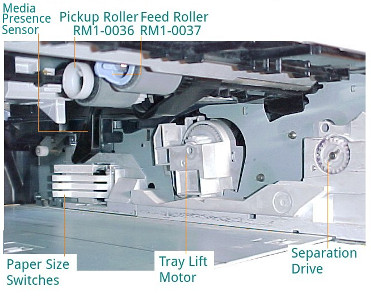

With a capacity of 500 sheets the paper is a bit too heavy to be lifted reliably by springs (although the LJ-4000 managed it). This tray uses a motor-assisted lifting plate like those in the LJ-4200 and P4014. The lift cog is on the right hand side and there is a lift motor RM1-4585 built into the printer. The lift motor is sometimes a cause of problems that might be blamed on the tray. The motor is briefly audible when you slide the tray in and confirm the paper type; its a brief and subtle noise but if it does not happen lift failure may be the problem. (Paper lifted into place can be viewed from the printer rear with the duplexer removed.)

At the back of the tray is an adjustable end stop. Moving the paper end stop sets some switch-arms on the side of the tray and these automatically tell the printer what length of paper is loaded. This mechanism amounts to a mechanical linear encoder -quite an intriguing thing to find on the side of a paper tray.

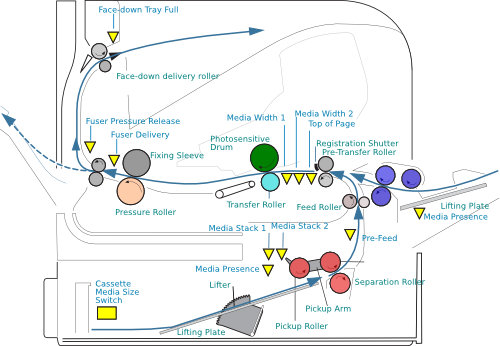

The paper path through the M601 series is an S shape from the cassette tray at the bottom, round, under the cartridge and drum, through the fuser and up into the output tray.

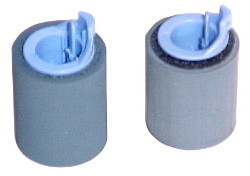

Pickup roller RM1-0036

Pickup roller RM1-0036

Feed and separation roller RM1-0037.

Cassette Feed Operation

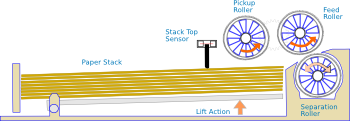

The pickup and feed process works as follows:

The pickup roller RM1-0036 is grey hard(ish) rubber on a foam rubber backing with a white bobbin and a moulded in 24 tooth gear. It lowers to sit on the paper at the point where paper feeds and pushes one or more sheets towards the feed and separation rollers.

The texture of the roller surface is sufficient to grip the flock of the paper and push it. All this roller has to do is push the paper about 25mm (an inch) forward in the tray to the point where the RM1-0037 feed and separation rollers take over. The RM1-0036 is driven via an idle cog from the same paper feed shaft that drives RM1-0037. We don't think the pickup roller gets much wear; hence it has a white core, it isn't particularly intended to be changed although it is just held by a latch so the job is perfectly easy.

There are a pair of RM1-0037 feed and separation rollers, one in the printer and the other in the cassette. When the cassette is in place the feed rollers are above and the separation roller below. This printer uses the same rollers for both purposes. (some printers have differently designed rollers).

The paper stack is held in position; lifted by the motor and stopped by the stack sensor above the tray. The top of the paper stack aims at the nip-point between the paper feed roller above and the separation roller below. The pickup roller aims the sheet into this point.

Feed rollers push paper round, up and into the body of the printer where another set of rollers take over and push the paper to the registration station where it is straightened and held so that precise drum timing can be got right. With soft rollers paper is easily propelled but timing is uncertain. With hard rollers timing is more assured.

The separation roller pushes against the feed roller. The separation roller attempts to spin the other way which would push the paper back into the tray. The feed rollers are more powerful so ordinarily, if one sheet picks up, they overcome the separation roller and the paper feeds forward.

Separation rollers are driven by a cog that protrudes through the right side of the cassette (right wall of the cassette space) and engages a cog on the tray. The drive power goes through three cogs to a torque limiter, a clutch in effect, or a drive shaft that has limited power. The torque limiter lowers separation roller power so that if no paper or one sheet feeds it turns with the feed roller. If two sheets get picked it has enough power to break them apart and throw one back into the tray - separation job done.

This three-roller separation mechanism is used on a lot of high end printers and copiers. It is not found on cheaper printers because it costs more to implement than the alternative roller-and-pad method.

RM1-0037 feed rollers. That on the left is fresh from the pack. On the right is a worn one showing a rather shiny surface and uneven ridges of wear. They do seem to change colour a bit as they age as well.

Faults

A few faults with paper feed are user errors; overfilling the paper stack, not setting the guides correctly, and leaving the end stop too slack or too tight for instance. There is some general help here. Use the little pointers embossed in the plastic to set things correctly.

The cassette tray itself is largely just a big piece of plastic. It isn't entirely dumb, the two guides are kept centred by a rack and pinion mechanism. On the standard paper tray notches and ball-catches in the mouldings spring the guides to the right positions. There is a paper-level pointer in the front and the paper-length encoder at the rear right. The paper length setting uses an interesting toothed grip mechanism. What mainly happens to cassette trays is that they get dropped and broken. The service manual lists no individual spares except the roller and the torque limiter - however the paper-stop / end-stop and a few others may exist. It does seem that if anything is going to break "spontaneously" it is the paper-stop.

A characteristic of the paper-stop being broken is that it will go forward - but not back. There is a cure for this but it's a bit complicated so we'll return to it below.

Common faults that might be blamed on the tray are paper jams; misfeeds or double feeds. Likely messages are:

13.xx.yy Jam in tray

with a misfeed, which is where the paper scarcely sets off.- With a double feed paper will get some way into the machine and give random jam errors of the

13.xx.yy Jam

type, but on clearing the problem there are two bits of paper found - one some way through and the other overlapping.

Misfeeds are incidents where the paper didn't really set off. They suggest a problem with either the white-cored RM1-0036 pickup roller failing to shove the paper forward or the blue cored RM1-0037 feed roller failing to overcome its separation roller partner - or the torque limiter. If the paper didn't get to the feed roller it suggests the former; if it was found out of the tray and up in the throat of the printer perhaps the latter.

Double feeds suggest a problem with the RM1-0037 separation roller not succeeding in pushing the paper back. However:-

If the rollers have been replaced and the machine still double feeds that could be the torque limiter being too weak. Demand for rollers is high. Demand for torque limiters is … limited! Change the rollers first and if that doesn't work try the torque limiter RC2-5771. It is on the same shaft and very easily changed. Note that the number is not written on the torque limiter but the part number differs from that in the P4014 which was RC2-5262. We do not know if RC2-5771 and RC2-5262 are actually the same thing. HP Partsurfer in June 2015 lists the torque limiter as fitting the P4014, M601, M602, M603, M604, M605 and M606 so we think its safe to say that if it isn't the same it should be better.

The only likely fault with these rollers is that the surface texture wears away, leaving the roller unable to exercise adequate grip on the paper. This kind of fault tends to appear when a tray is rather full or nearly empty - or with paper that has become slightly tacky with damp (at the margins of its working parameters).

Most people find that for the price of a set of rollers it simply isn't worth trying to diagnose which is worn - both or even all three will be. Hence they are sold in kits.

Changing Rollers

The rollers are fairly easy to change, the only problem being that if you are not familiar with the job it can be difficult to see into the dark recess where the cassette goes. For this reason we suggest changing the cassette roller first because it is easy to see. Take the cassette completely out of the machine, and lift any paper out. There is a little access hatch beside the roller, open it. There is a tab on the roller and a latch, pull the latch toward the tab and the roller is free of it's shaft. Hold the new roller by its tab and push it on. Locating recesses fit over lugs on the torque limiter.

The roller(s) in the printer work in much the same way; a difference is that you may need a torch to see them in the cassette recess. With a little practice it is possible to change them by feel with your eyes closed but that is probably not a worthwhile skill! Whether you need to change RM1-0036 is up to you. If you drove to site to do the job then definitely - but users are supposed to be able to change these themselves. Check if it seems worn.

If changing the rollers doesn't cure feed problems then read on.

Clones

As you probably know there is a large counterfeiting industry making clothes, toys and electrical goods and particularly printer cartridges - … - even things like printer rollers. Counterfeiting tends to break out wherever a brand charges a premium over the manufacturing price. The premium might cover R&D, QC and support (good) or advertising and junkets (not so great).

Clones are things not made by or for the brand and sold as equivalent. If the clone does not breach a patent or copyright it is legal and legitimate. However it is not legitimate to pass a part off as having the brand-name when it does not.

We don't sell "clone" parts unless manufacturer originals are not (or no longer) available. This sometimes happens for HP printers more than 10 years old, or where replacing the whole unit is economically feasible. Many of our customers are field service people who have to drive to site, identify a fault and fix it - and don't want to return a few days later because of a faulty spare (for our own experience read here. If we are selling clone or refurbished parts rather than HP/Canon originals we say so.

Clones are no all utterly bad. If there were no possibility of clone parts manufacturers might force good printers onto the scrap heap after just five years (at least one of the lesser printer brands is trying just this in 2015). HP and Canon have generally been good at providing original spares at reasonable prices (for laser printers).

Even with something as simple as a pickup roller and pad there are an infinite number of possible differences in formulation, pattern and dimensions. The manufacturer will not willingly make information available so the clone maker is reduced to making impressions of parts and guesses about materials. They are plastic injection moulders, not printer makers and may not appreciate how the part works.

If a part on Amazon or eBay looks cheap that is probably because it is a clone. Vendors of shoddy clones hide behind eBay and Amazon because they are unlikely to be pursued, and if anyone complains they rise again with a different trade-name and account. One way to tell a bad clone is to look at the moulding closely. Surfaces that should be shiny are mottled. Surfaces that should be flat are convex or concave. Things that should fit easily and precisely are tight or slack. Rubber formulations made with cost rather than durability in mind don't last. In spares, the bargain that is too good to miss is too good to be true.

Originals, Clones and Counterfeits

HP charge quite a bit for a new RM1-4559-020CN cassette (just shy of £60 in June 2015). There are two possible sources: HP themselves and "refurbished".

Rollers are different - and more interesting. HP Partsurfer says Part RM1-0037-000CN is no longer supplied. Please order the replacement, Q7829-67925

.

These parts are known by three codes: RM1-0037-000CN, RM1-0037-020CN and Q7829-67925 The -000CN suffix is HP's code for a Canon part. Numbers in the suffix change when something is revised, so most recent rollers come with the code RM1-0037-020CN.

The "Q" prefix is used by HP when they are trying to make some distinction. Parts with this code are often identical to some other but perhaps more expensive. The Q7829-67925 does appear in UK distribution but usually in small numbers because distributors think they know HP's game here. The HP code was a Canon part. Very often, if you buy the HP code you get the Canon part - with either HP or the distributor silently making a substitution. Distributors shouldn't make silent substitutions but certainly have done this in the past. In these circumstances we generally sell the Canon part, it is cheaper and more widely available. If you specifically want an HP product we can attempt to supply it (assuming the distributor doesn't switch codes.

HP might use a different formulation of elastomers to that used by Canon (butyl, butadeine, polydimethylsiloxane / silicone, PVC, polypropylene etc ); it is certainly true that neither they nor Canon are inclined to tell anyone what the formulation is - all printer manufacturers have their pet patents and materials. There are at least three "legitimate" rollers with slightly different appearances doing the same job.

Print brands don't say what materials they use, presumably to avoid helping counterfeiters. Counterfeiters probably don't care, since their concerns are a rough match in appearance and then just price.

It would be possible to make a better roller than HP / Canon. HP patented grit rollers back in the 1970s and they lasted very well - but they would be expensive. Everyone is ultimately concerned with price.

The full cassette is a complex assembly with a fairly limited market. It isn't available in a Canon version, there has never been a direct equivalent of the LJ-4200 / P4014 / M601 / M604 series. Making a tray is quite complicated but third-party manufacturer "2-power" apparently has product - they normally make laptop batteries. That may be why the complete RM1-4559 is expensive, -nobody much clones it. They may be cloning some of the parts and if so that may be a good thing (more below).

Demand for the rollers is quite large and they are quite simple so there are also some nasty clones.

Other Paper Feed Problems

The switches that communicate paper size were a known trouble spot in older printers - users are inevitably a bit heavy handed about sliding the tray in - when loaded with a ream of paper it weighs nearly 3 kilos. HP seem to have improved things by incorporating a couple of glide-wheels on the side. On older models after a while the switches misbehaved ( they aren't difficult to replace but we just hardwired one of ours to A4! )

Problems that seem to relate to the cassette can be the sensors. Every sensor on this printer is individually testable.

The lift-plate drive motor can be a problem, particularly when people ram the cassette home. The motor disengages because it is held by a spring and if people are rough they can knock the spring off. Take the duplexer off the back of the machine (or the blanking plate if there isn't one) and have a look in the back - the paper can be seen rising into position.

Web Research

HP Partsurfer says:

- HP-RM1-4559-000CN Tray 2 cassette

- RM1-4559-000CN 500-sheet paper cassette tray 2

- RM1-4559-020CN 500-sheet paper cassette tray 2

- RM1-4559-BULK CASSETTE

- RM1-4559BULK Tray 2 Cassette

This part might also be known by HP's full code is RM1-4559-000CN, and possible later revision is RM1-4559-020CN

An interesting fault we came across during research is cassettes getting utterly jammed in the printer. The cover over the separation roller is held in place by open-ended plastic clips and held closed by a spring. If someone bends the cover too far it will come off and may be replaced with the spring off or positioned so that the cover doesn't spring closed. If it then comes open in the printer it will jam up against the ridges at the top of the cassette recess. The solution is to get into the space from the rear if possible and push it back down.

Supply Situation

We research pricing from time to time. In September 2014 these trays are available new and refurbished; new about £56.00, are in stock. Refurbished are about £34.00 and are in stock. Refurbished trays should be clean and have a new RM1-0037 roller and any cosmetic blemishes should be minor. Prices had increased a few pounds in June 2014, perhaps reflecting currency shifts or maybe HP policy. For up to date prices see the catalog .

Stock numbers for new trays vary with time and in both September 2014 and June 2015 at least 5 distributors were showing stock levels suggesting they might hold a pallett as stock. That indicates there is quite a high demand for the part. IT departments with fleets of these printers keep one or two trays is stock so that accidents don't bring a printer to a halt.

We will usually be able to ship trays for next-day delivery.

|  |  |  |

|  |  |  |

|

Repairs and Spares for Trays / Cassettes

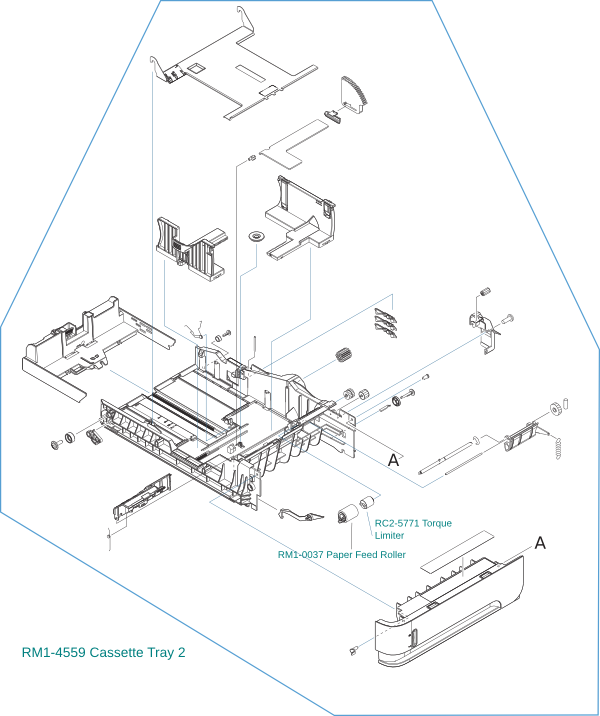

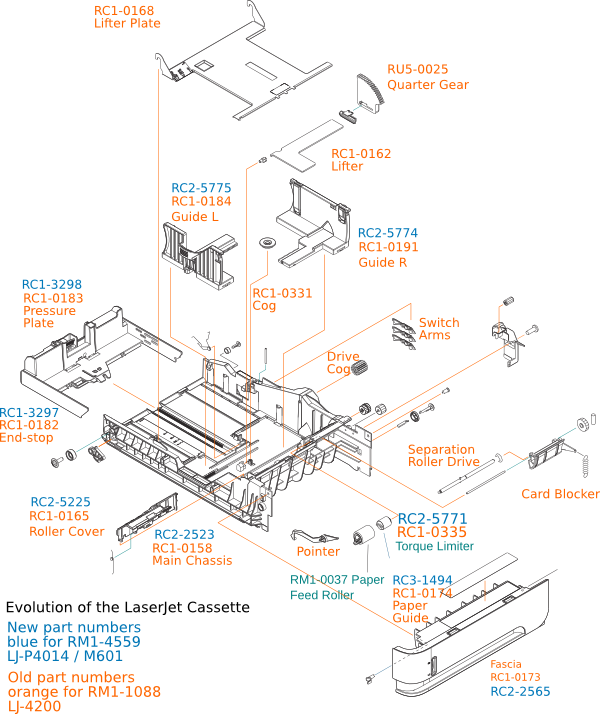

This exploded diagram shows a reworking of the service manual diagram for the M601 series printers (part CE988-90945

). As shown, non off the parts are labelled as available individually except the roller and the torque limiter.

An obvious question is whether these cassettes always break the same way. On average we think the dropped trays will break in a variety of places so that if you have a heap of several broken ones then a bit of triage amongst the parts should make a good one.

However there are signs of a common break point - the paper end stop.

Repairing the Back Stop

From the LaserJet 4200 onwards there has always been a definite weakness in the end-stop, paper stop or back-stop (whatever you want to call it). A typical fault is that when you try to adjust the stop it will move forwards to the front of the tray, giving smaller paper sizes, but not back. If you keep on trying it will nudge up to the metal lift tray and that is the end of travel. The stop will not move back unless you dismantle it.

Dismantling is not self-evident. If the end stop is up against the lift tray, first get the metal tray out. It is held down by a couple of clips, bumps on the left and right guides and the paper level pointer at the front. Open the left and right guides fully, they push aside and the tray swivels round and lifts off its hooks. The paper-full pointer pushes aside as well. Now the end-stop rack and grip mechanism can be seen.

What will have gone wrong is that the blue latch has lifted out of the white nylon slider. The slider opens jaws in the "nose" of the end-stop. With these tight against the rack moulded into the tray base they prevent the end-stop moving. The little jaw mechanisms are visible at the front of the slider; hold them open with a paperclip or screwdriver and the end-stop can be moved back. When it is fully back the handle can be lifted back into place on the slider so that the end-stop can be moved both ways.

Characteristic of the problem is a crack down the centre left of the paper-stop just by the blue handle. This point seems to be weak in successive refinements of the cassette. We doubt HP want the cassettes to be weak, although they probably do sell in tens of thousands worldwide. They just seem to forget to fix the plastic although they have attended to everything else.

Progressive refinements have been made to the blue handle, the white nylon glide that it is supposed to mate with and the position of the spring. but only time will tell if these improve reliability.

Parts List

HP haven't produced a public list of the parts for the cassette. Presumably this is on the grounds that no one can be bothered with trivia worth less than $100. To see if there is any interest we made one.

Although there is great similarity between the LJ-4200 cassette and that of the P4014/ M601 the chassis they differ in several important respects. The outside is notably different with the newer device getting a set of glide wheels, some in the printer and a couple on the tray. There is also a stop to prevent people .

The standard/custom paper-selection knob disappeared, there is now a different cassette for non-standard sizes.

RC2-5225 was RC1-0165 Roller Cover. Changes to the top surface possibly intended to improve seating and stop it flipping open with the possibility that the tray jams in the machine

RC2-5775 was RC1-0184 Guide L. Changes the ABS with a metal bar inserted for a POM/Nylon insert. Straightening of the curved front

RC2-5774 was RC1-0191 Guide R. Redesign of the blue locking handle to be the other way round possibly making it easier to work with a paper stack in place.

RC1-3297 was RC1-0182 back-stop or end stop. Redesign of the area around the blue locking handle. Substantial redesign of the way the locking handle engages with the POM/Nylon locking-jaw slide. Also a slight redesign of the rail that holds the mid-area of the backstop down to the mid are of the tray; it is longer, presumably to resist breakage but has lost the chamfer that made assembly easier.

RC1-3298 was RC1-0183 back stop pressure plate. Added a forward facing and backward facing hook or protrusion. The forward facing hook just improves the way the pressure plate locks under the main moulding of the end-stop. The backward facing hook interacts with a new protrusion from the blue handle so that when it is operated it withdraws the plate from any paper on the stack. This replaces an older latch design, where an upward protrusion from the nylon locking-jaw slide pulled on a downward projection of the pressure plate.

RC3-1494 was RC1-1074. Substantially redesigned in terms of moulding as a much more sold block rather than the rather complicated comb used in the past. This might be a matter of getting manufacturing yield up and the new part might be less easily broken in use.

RC1-0168 is similar but has acquired a black textured felt-like pad instead of the white nylon material.

Available Parts

There are some cassette repair kits

The RM1-1088 cassette used in the LJ-4200 is was refined over time so that it's part number rose to RM1-1088-090CN.

It doesn't seem to be mentioned in any service manual, but at some point the "rear tray assembly" RM1-1089-030CN was introduced. Whilst it seems intended for the LJ_4200 cassette it will work in more recent versions and since it is cheaper than a complete cassette that is almost certainly a help. Looking in the parts lists in June 2015 we don't see any part specifically for the more recent printers - but that wouldn't be necessary.

There may be "third party" versions of parts as well.

Printertechs offer one "Paper tray stop for the 500 sheet paper trays in the HP Laserjet 4200, 4300, 4240, 4250, 4350, P4014, P4015, P4515" This has no part number so presumably it isn't an official HP part. There is a warning theat there are several small parts taped in position. The assembly is not returnable if parts are missing or broken - and it isn't cheap at $32 - you can always buy the replacement tray instead.

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site useage patterns.