HP Original Cartridges

Unbeatable quality and reliability

Procopy Remanufactured Cartridges

High quality, at low cost

Laser Scanner Units

New

New laser scanners are sourced from HP's official parts distributor network, however this part is not widely required and there is little or no stock in the UK or Europe. It will normally take 7-10 days for the logistic-chain to operate and deliver a product. HP standard warranty on spare parts is 90 days. We recommend new units to customer service engineers who have to drive to site because using HP original parts give a higher degree of confidence to you and your customer.

Refurbished

Refurbished devices are sourced from UK service and spares outlets with surplus printers. In this case "refurbished" means a "pull" from a working machine. Warranty is generally 90 days as well - however you are expected to have skills and knowledge to sort out minor issues like a spring or shutter being dislodged yourself. We recommend refurbs to on-site engineers and support technicians because the savings are substantial. (Refurbs can be used to just prove a fault clears).

As the remainder of this article should make clear whilst the laser unit might sometimes be suspected of a fault it rarely fails in practice and the printer is highly likely to give "51" errors on the control panel and in the error log if it does. Even then, some repairs can be made as outlined below.

User Repair

Replacing a laser unit is not a challenging task but it does mean removing covers from the printer, handling static sensitive parts and there is a small possibility of foolish actions exposing your eyes to laser damage. If you are inexperienced with electrical things start with a less valuable printer.

New Printer

Whether you chose to repair a laser-fault at all probably depends on how much you have invested in the printer. If you have two large cartridges in the stock cupboard that is £300 worth of material so if the machine is giving "51" errors and will almost certainly be cured by a new scanner it's a worthwhile gamble.

The lowest cost new equivalent to one of these machines is the M604n. A typical replacement would be the M604dn which has the duplex unit. As you might expect, they do not take the same cartridges as the older machine.

-

E6B67A HP Laserjet Enterprise M604n

Please email us to confirm availability

A4 Mono (B&W)

LAN, USB

5,000 - 13,000 pages/month

10,000 page cartridge

-

E6B68A HP Laserjet Enterprise M604dn

Please email us to confirm availability

A4 Mono (B&W)

Automatic Duplex

LAN, USB

5,000 - 13,000 pages/month

10,000 page cartridge

HP RM1-7419 laser scanner for HP P4014 and M4555 Series Printers.

… … with some observations on the M601 and M604 series and on laser scanners in general.

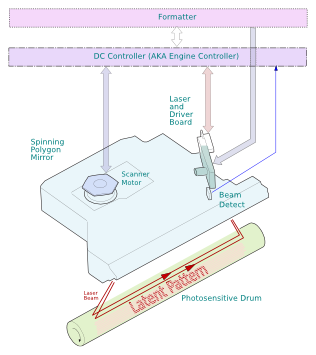

The laser-scanner is the part of the printer that actually creates an image of the page by raster-scanning the photosensitive drum. At 1200 dpi an 11x8 piece of paper holds 126,720,000 pixels and a fast printer has under a second to produce that. Both laser and motor are working at speed and with precision of a few microns.

A printer could use any light source- CRTs, LEDs and LCD light shutters have been tried. OKI adopted LED printheads some time ago and are rightly proud of their unusual technology. However most manufacturers have stuck with laser scanner units.

Laser beams give a small, intense spot of light of a specific wavelength. The laser is scanned across the drum by a rotating multi-faceted mirror - in this case it has 6 sides. Discos use large versions of the same idea to bounce coloured spot-lights off the walls but don't try that with a printer scanner as the beam is small and at an invisible wavelength - but capable of blinding by destroying your retina. Technicians with a fleet of these machines to look after rarely need to work on a laser scanner, if it does happen keep the power off or the lid on! Or buy yourself laser-protection spectacles. A laser is not a toy!

How Lasers Fit Into Electrophotography

Laser printers are part of the "electrophotographic" group of machines first invented by Chester Carlson in the mid 1930s and brought to market as the Haloid Xerox 914

in 1959. After a couple of years the company changed its name to Xerox and over the next ten years it became an industrial giant. Photocopying revolutionised the way an office could work.

In the 1960s IBM was the other force aiming to combat the "paperwork explosion". As they competed, Xerox researched computers, IBM researched copiers. Gary Starkweather and a small team at Xerox PARC developed the first laser printer by modifying a copier with a laser scanner and a formatter in 1972; however the company didn't market the machine until 1977.

IBM were first to market with the 3800 laser printer in 1976. IBM experimented with using a fibre optic faced CRT and an LED array to illuminate the drum, but they weren't reliable when mixed with the high voltage fields used in the copying process so they replaced them with a gas laser and a precision made polygon mirror. These were expensive devices, upwards of quarter of a million dollars to buy but nearly always leased. They were fast though, the 3800 worked with continuous paper at 32 inches per second or about 180 pages per minute. Xerox's 9700 ran at 120 pages per minute with cut-sheet paper.

HP was the first to market an easily affordable laser printer with the "LaserJet" in 1984. Based on Canon's newly developed personal copier

it used a print cartridge for toner, developer and drum but reversed the voltages to write-black instead of write-white. The semiconductor laser was based on those developed for CD players. The formatter was based on a Motorola MC68000, which was also the basis of the original Apple Mac. Cost at introduction was just $3,495 but throughput was just 8 pages per minute.

The heart of the printer is the OPC drum in the cartridge. OPC (Organic PhotoConductor) is a layered plastic sandwich. The top layer holds a charge, whilst the middle layer acts as an insulator in the dark but becomes conductive in light and will then drain that charge into the metal of the drum. (It's an approximate explanation, semiconductor scientists will offer more sophistication).

The OPC can be seen under the shutter on the underside of the cartridge. In operation the laser points through a slot in the cartridge top. The OPC is initially charged (negative) by a roller. Regions of the OPC that are to become black are discharged by the laser-light. Varying charges on the drum form a "latent image" which is then shaded or "developed" by the toner powder. Toner is also given a negative charge, largely by friction between the developer roller and blade (triboelectric charge). Like charges repel, so toner will not stick to the remaining charged areas of the drum, however where the laser has written the charges are different and so the charged toner does stick forming the developed image. This technique is sometimes called "write to black" or "blackwriting". With ordinary 5% page cover the laser is only on for a twentieth of the time. Printing solid black pages will not only use a lot of toner, it might prematurely age the laser.

If the laser were to die then the OPC drum would not be discharged and in principle the machine might produce white pages. In practice that won't happen because at least two signals prevent it: Beam Detect (BD) from the optical unit and PD (Photodiode) from the laser unit can be checked by the DC controller to confirm the laser is working. If you do get white pages the cause is likely to be something else, such as the mechanical interlocking for the laser beam shutter not seated correctly or a failed transfer voltage circuit.

The laser power and wavelength matches the properties of the optical photo-conductor (OPC). The laser is quite similar to those used in CD, DVD and communication devices working at near-infra-red wavelength and possibly a bit more powerful.In this case it's a dual beam laser unit and the service manual says this speeds things up. There has been some online debate over precisely what the dual beam does. There are a series of patents such as US5745152 which suggest it might be used for improved resolution or halftoning at a given speed. Dual beam seems to have first been demonstrated by Bill Holland of HP Labs to Canon in 1994, then adopted in HPs larger printers. (William Holland is a co-inventor of the optical mouse).

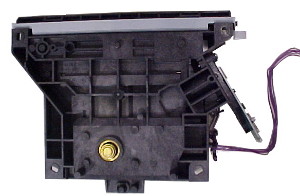

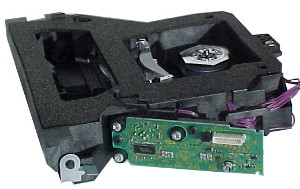

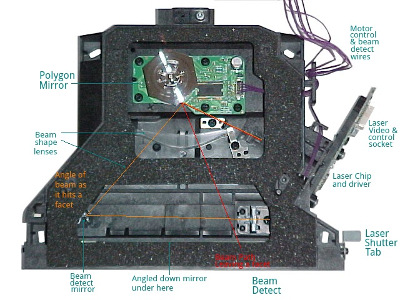

Structure of the Laser Unit

The laser unit has several parts: the laser itself mounted on a circuit board, the polygon mirror which makes the beam scan, and then the rigid plastic mounting that holds these and a set of lenses to collimates and shape the beam. Finally there is a mirror to point the beam down into the drum slot on the cartridge.

HP have kept very much to the same design of laser unit for a long time - the decade old LJ-4200 laser unit is almost indistinguishable but all the part numbers are different - even the metal shutter which looks identical except that it is no longer spring-loaded. Laser printer designs may look different from the outside but on the inside evolution is the natural order.

HP Part RM1-7419 is specifically said to be the laser scanner for Hewlett Packard LaserJet Enterprise M4555 printers. RM1-7419 also replaces RM1-5465 which the P4014 service manual says was used in the P4014, P4015, P4515. (RM1-5465 should not be presumed forward-compatible - it may be but we can't speak from experience. ) A laser unit taken from a printer may have different markings - such as RU5-8126

which is actually the number of the Canon laser warning label - not the part. The warning label on an M602 says RU5-8841

. eBayers see these numbers, presume it is the part number and so effectively it has become so! Part numbers are dealt with below.

The laser scanner is primarily made from black rigid plastic with a metal lid. The underside of the plastic says >PC+SAN-(MS+TD)25 FR(40)<

which is polycarbonate and styrene acrylonitrile. Part number on the moulding is RC2-2246

The assembly is roughly triangular but has a green circuit board mounted on one side which carries the semiconductor laser emitters and their control chip(s). Towards the apex of the triangle is the polygon mirror on it's motor spindle and at the base is the laser shutter covering the angled mirror. When mounted in the printer the shutter has a mechanical interlock so that it ordinarily won't open unless the lid and cartridge are in position. When a cartridge is in place and the lid closed the shutter is open so that the laser can shine through the slot onto the cartridge drum and create the image. Off to one side of the mirror is another little mirror which catches the beam just before its starting point and reflects it at the beam detector. When BD is triggered a stream of 10,000 picture elements (actually 8.5 x 1200 = 1,200 for A4) is fed from the formatter through the DC controller to the laser.

This is what the P4014 service manual says about the laser scanner …

- As it receives a print command from the formatter, the dc controller outputs the SCANNER MOTOR SPEED CONTROL signal (/ACC) and rotates the scanner motor in order to rotate the six-sided mirror.

- 2. As the scanner motor starts rotating, the dc controller uses a LASER CONTROL signal (CNT0, CNT1, CNT2) to receive the /BD INPUT signal (/BDI) and force the laser to emit light . The dc controller detects the rotational speed of the scanner motor based on the timing the /BD1 signal is input and controls the speed to keep it constant.

- 3. While the scanner motor rotates at a constant speed, the dc controller passes the VIDEO signals from the formatter on to the laser driver PCA. The laser driver PCA emits light from the two laser diodes according to these signals: VDO1, /VDO1, VDO2, /VDO2.

- 4. The two laser beams pass through the collimator lens and cylindrical lens and strike the six-sided mirror that is rotating at a constant speed.

- 5. The laser beams, that are reflected off of the six-sided mirror pass through the focus lens and reflective mirror and focus on the photosensitive drum. The laser beams scan the drum surface at a constant speed.

- 6. As the six-sided mirror rotates and the laser beam scans the drum surface at a constant speed, a latent image forms on the drum surface.

Laser Control

At one side of the unit is the laser control board. With an RM1-7419 this seems to be RM1-4509

; the mask overprint also calls this RK2-1648 02 which is possibly the PCB number. The laser is controlled via a 12-pin connector and a chip RH4-5455 88ZU5A JG4

. At a guess this will have been made specially for Canon/HP, searching for a datasheet produced nothing of clear relevance.

Although the circuit board uses a 12 pin header the P4014 service manual schematic suggests 11 are used. They are labelled: VD01, /VD02, CNT0, CNT1, CNT2, VD02, /VD02/ LPH1, PDOUT, GND, 5V. These are 5 Volt and ground as power supplies. Video for the lasers comes from two balance signal twisted pairs VD01 /VD01 and likewise VD02 /Vd02. PDOUT tells the DC controller the beam(s) are on. Quite what CNT0, CNT1 and CNT2 do is not entirely clear - or LPH1 - (laser power?)

The same diagram is used in the M601 service manual. The part number is changed to RM1-8406 and the circuit board in an M601 printer says RM1-8370 has a 13 pin connector and has a prominent label saying 3.3V, so they are different - but in the M601 series service manual the old diagram is re-used. The later M604 service manual has clearly been redrawn, differing in many respects; the part number is still RM1-8406 and the manual shows the same pin-propositions as the P4014 but the power is now amended to 3.3V - .

It is not at all unusual that the M601 manual gives the wrong voltage. In the last few days we have dealt with a Brother manual getting two roller assemblies the wrong way round, resulting in a customer buying the wrong thing, and with an OKI manual simply failing to show or list one roller at all and listing parts for kits that make no sense.

In recent times the laser itself rarely fails outright. Semiconductor lasers are said to fade to half power over about 20,000 hours but a feedback loop using PD corrects for this. If the laser fails or cannot give the correct intensity a " 51" error would be expected. Most sudden faults are likely to be the polygon mirror motor bearings. The printer should report error code 51.10.

The laser can be seen on the circuit board, there are pins labelled COM, LDA, LDB and PD. If those terms are fed to Google it finds things such as US patent 2008/0013577 to Saitoh and Watanabe of Texas Instruments for Light Emitting Device Driving Gear - and the patent has applications to control of laser power.

Lasers commonly have a feedback loop through back-diodes so inability to form a beam would be detected this way. There are some suggestions on the Web that if one laser fails alternate lines have different densities, spoiling the print quality. This does seem credible, there are two laser drives LDA and LDB but one feedback diode PD.

Another point that might just save someone somewhere the cost of a scanner. The laser circuit board uses surface mount components but the laser diode has through-hole mounted leads that look hand soldered - or it could be dry joints. Lasers run hot so dry joints wouldn't be a complete surprise.

Polygon Mirror

Inside the enclosure is the polygon mirror and motor. The mirror is 6 sided, each facet corresponds to one sweep across the page (of two beams). Don't touch the mirror (or at least, not if you intend it to survive) as the shiny surface is on the outside - and not as you might expect inside the glass. This is common with laser apparatus, glass absorbs energy so the silvering is outside. If you must handle the mirror use gloves or something like soft, lint free tissue rather than sweaty hands.

The motor board is labelled RK2-1649

and BN35-01400

and the controller chip M63151FP RH4-5411

. This a driver and controller for use with three-phase brushless motors, specifically designed for polygon motors. The chip is a 42 pin device but 8 of those are ground/heatsink pins and there are various capacitors used for timing and resistors for current control. There are actually just four input wires: ground, 24 volts, Accelerate and Decelerate - the printer gets speed information from beam detection (BD). The P4014 and M601 series use the same polygon motor scanner.

The polygon mirror needs to rotate very rapidly and keep its position accurately. If there is the least problem in the bearings the image position will jitter - a vertical line examined closely will have dots offset. The printer detects the beam at the end of it's travel (BD signal), so it should be able to report any error. However in the past laser printers have not always succeeded in detecting this kind of instability. Printing a configuration page might help to eliminate problems such as the printer being asked for 300DPI instead of fastres 1200

and suchlike.

It might seem that anything so precise as a laser scanner would be completely unrepairable; that hasn't always been true. A frequent fault in other printers when they get old is that the polygon mirror motor becomes unstable or actually jams. Take the screw off (in some printer designs its a circlip), lift the mirror spindle out and clean it and the shaft and it will work again. A couple of drops of machine oil will probably restore operation for a long time. Other than this repair is probably limited to cleaning the optics - mirrors and lenses inside. The laser assembly itself needs precise factory alignment and most workshops would not be able to do it. The polygon motor might be replaced but they are probably not obtainable in small quantity.

Beam Detect

At the bottom right of the scanner unit is the beam detector. It actually seems to be triggered from a little mirror at the bottom left which points between it and the polygon mirror at the beginning of a sweep. The circuit provides ground and 5V power and has one output /BD. If the motor failed to spin or couldn't maintain speed software on the DC controller would presumably report error 51.10.

Flow of Control

The Laser Scanner motor is controlled by the DC controller RM1-4582.Video data primarily comes from the formatter and is only relayed through the DC controller. The DC controller can superimpose a video signal, which is what it does at engine test -(the little button hidden in the right hand side). If you have doubts whether a fault could be formatter, DC controller of laser try an engine test. If the laser(s)work at engine test, then suspicion falls on the formatter. The base model formatter is CB437-69002 -and CB438-69002 is the formatter for the rest of the series.

To see RM1-7419 in context in the engineering diagrams click here.

Access to the Scanner Unit

To get at the laser scanner it is only necessary to remove the top cover, which is just a matter of disconnecting the release arm and taking out four screws (two of them under the accessory cover). However to take the laser scanner out it is necessary to remove the right hand side of the printer in order to get at the motor cable connection into the DC controller There is help with how to do that here.

Parts Information

One of the problems with parts like the laser scanner unit is that the part number on the device is not what is given in the service manual or in HP's online data source PartSurfer.

Component parts have part numbers of their own, of course. We mentioned the label numbers above: The RM1-7419 P4014 series scanner unit seems to have a warning label RU5-8126 whilst the M601 series have the warning label RU5-8841. Because these numbers are prominent on top of the laser unit they tend to be taken as the part number.

Both P4014 and M601 series printers share the moulding RC2-2246 and the polygon motor RK2-1649.

The significant difference is that RM1-7419 (P4014/M4555) has laser unit RM1-4509 on its side. RM1-8406 (M601 / M604) has laser unit RM1-8370 which, in addition to having an extra pin on it's connector and being physically marked "3.3V"

A white label saying RM1-4511 1CE, is for the P4014, P4015, P4515 and M4555 printers where part RM1-5465 or RM1-7419 are given in the service manuals. Another possible number seems to be RM1-8074.

A white label saying RM1-8373 1CE is for the M601, M602, M603, M604, M605, M606 and M630 printers where service information gives RM1-8406 as the part number. It seems that RM1-8373 is a "factory number" whilst RM1-8406 is a service part code. Factory bill-of-material information and service information resemble one another but are different.

The text in the table below seemed a bit squitty, so as an experiment I decided to make it grow on mouseover - its probably a bit disruptive but I thought I'd leave it in

HP have showed some concern that people buy "refurbished" second hand spares rather than original new spares. However in this case they play straight into the hands of eBay dealers. The number the service engineer sees is what the eBay trader advertises. HP give completely "wrong" numbers that can't be found in the machine. Service manuals are easy to get (in HP's case) but run to hundreds of pages and need some interpretation.

HP Information

Sometimes we have to find parts information from printer manufacturers by a combination of several methods; the service manual says one thing, the printer contains something that appears different and says another or omits something.

We have done two lots of research on the P4014 laser scanners, one in 2013 and another in 2015

2015 research

In 2015 HP didn't seem to have changed its data so rather than entirely repeat the same exercise we tried a different tack. Most of the part numbers known were taken (sometimes in several varieties) and tried on Partsurfer, on Recoll which we use for internal information like service manuals, on an internal list called "allprices" which lists the information we get from UK and EU distributors. we also fed the same codes to Google

| Part | Partsurfer | Internal Doc | UK Distys | |

| RM1-5465 | found | 57, P4014 P4014 SVC and lists | Not found | 4,310 results |

| RM1-5465-000CN | replaced by RM1-7419-000CN | 19, P4014 P4014SVC and lists | Not found | 1,690 results |

| RM1-7419 | not found | 33, M4555 SVC some lists | 4 lines | 2,250 results |

| RM1-7419-000CN | 8 found for M4555,some P4014 | 6, M4555 SVC | 3 lines | 977 results |

| RM1-4511 (side) | blank return | 4, own articles | Not found | 1,590 results |

| RM1-8406 | not found | 44, M601 M630 M604 SVC | 3 lines | 1,740 results |

| RM1-8406-000CN | 24, M601, M604, M630 | 18, M601 M630 M604 SVC | 2 lines | 776 results |

| RM1-8378 (side) | nothing, article not indexed | Not found | no results | |

| RU5-8126 label | not found even as -000CN | 7, CAN_IR1610,LBP-2410 etc | 2 lines (HP,CAN) | 736 results |

| RU5-8841 label | not found even as -000CN | 1, this article | Not found | 419 results |

| RM1-4509 (laser) | not found even as -000CN | 1, this article | Not found | 715 results |

| RM1-8370 (laser) | not found even as -000CN | 1, this article | Not found | 275 results |

| RK2-1649 (motor) | not found even as -000CN | 1, this article | Not found | 2 not relevant |

| RC2-2246 (mould) | not found even as -000CN | 1, this article | Not found | 82 results |

2013 research

In 2013 our approach was to try to confirm that RM1-7419 definitely did replace RM1-5465 and that proved true. We didn't then know why RM1-8406 was different - because it replaces the 5V laser board with a 3.3V version. Incidentally the new research gives the same results.

A query on RM1-5465 to partsurfer returns:

RM1-5465-000CN Laser/Scanner assembly - Mounts on the support structure in the print engine frame assembly

Part RM1-5465-000CN is no longer supplied. Please order the replacement, RM1-7419-000CN

... so confirmation of the service manual assertion that the part is RM1-5465 but it has been replaced by RM1-7419.

RM1-8406-000CN Laser/scanner assembly

... and lists the LaserJet Enterprise 600 M601N, M601DN ... M602, M603 etc.

The Enterprise M4555 seems to be the pinnacle of the P4515 series rather than a member of the M601 series - although there are overlaps they don't include the laser scanner.

Web Research

A Google query on the code RM1-7419

in 2013 gave About 105,000 results

and a list of vendors:

Amazon (ZAR Systems) £467.00, eBay (pcbaby) US $350.00, Lambda-tek £243.20, eBay (LaserXperts - strepx ) £19.32 -£29.50, eBay (action-guy) £18.34 - US $28.01, Morecomputers £297.09 with free delivery but no stock, Printerworks £404.20 new £77.83 refurb, Brokenprinter $119, sparepartswarehouse new $399.29 refurb $328.31, databazaar $161.91, Amazon refurbished from $155.8, Laserpros no price, 360tech $145, Techworldparts used $34.99, Printertechs $175, Txo-systems RFQ, Laptops2desktops $199.00, Icecat no price, Bargainseekr $199.00, Techpartswarehouse RFQ, Yoursourceglobal refurb $145.00, Partsnow login for price, usaprinterguy $199.00 sale $155.88, Memory4less $229.63 discounted to $195.18, IDNS no price, Dectrader $333.00, Rapid-tech no price, Print4everexpress $0, Zauba (broker), Mynordicbroker (broken link).

In 2015 we haven't yet repeated the exercise because we think it will get a different list but similar results. HP have pulled their price down a bit but that still results in a distribution price over £200 and no UK distributor holds HP new stock. Prices noted are for a new item without tax by default. However these items are frequently sold "refurbished" and that isn't always made clear - anything sold for less that £200 has to be refurbished and some of those for much higher prices were too. The list is as encountered. We haven't bothered with currency conversion because of our readers are often outside the UK and more interested in dollar prices.

Printertechs were the only site that offered any information beyond what was discoverable from HP Partsurfer and distribution lists.

Fitting a new laser assembly is not difficult but might be a job for an experienced technician. The top and sides have to come off the printer so the laser itself and its cables are accessible. The laser unit may need alignment in the factory but as supplied it is pre-aligned to the chassis. The laser assembly is held by a few screws and a new one just drops into place, screws down and the wires need attaching. There is no setup procedure.

Supply Situation

There will probably be one global manufacturer for laser scanners like HP RM1-5465 / RM1-7419. Researching the moulding code RC2-2246 did suggest one Chinese manufacturer claiming to have new compatibles but we find that hard to believe - the market for these things is tiny. Did a box drop off a lorry? Compatible manufacturers presumably won't attempt to make something quite complex like this and with a small market profile. In July 2013 these parts were available from two sources - HP new and other vendors offering refurbished.

HP have dropped their prices a bit. In 2013 a new laser scanner was about £250 in the UK, in 2015 it is £ 220 . We have reservations about the quality of compatible parts but a challenge to HP's price for a new item might be welcome. A laser-scanner is markedly less complicated than a CD player. The price of new laser scanner units has always been high - sufficiently to act as a disincentive to repair. However these were fairly expensive printers in the £550 to £1500 range and replacing one with a LaserJet Enterprise 600 M601dn will still cost about £590. On the other hand a complete M604n can be had for £330 or so. If you are quite clear that the fault relates to the laser assembly because error code 51.10

or similar is displayed then a new RM1-7419 laser assembly might be warranted.

Our research suggested an enormous range of refurb prices from £19 to £467 and no real consensus. We doubt "refurbished" means anything more than "used". We wouldn't normally open a used item up to clean the optics or bearings unless we tested it extensively afterwards. Testing the brightness of the dual beam laser might be possible but the easy way to do that is to verify the machine print quality. There is not a great deal of refurbishing that makes sense - for instance if the optics are dirty then the item might clean up but it probably shouldn't be sold. For "refurbished" read "used".

The part is listed as new by a couple of distributors in the UK under RM1-7419 but they don't hold stock. RM1-5465 was not mentioned in the distributor lists, neither was RM1-4511 or RM1-8074. We think demand for the part will be low under any name - laser don't fail much.

We can provide these parts new or refurbed when required. We think brokers will provide one by dismantling a printer for about £30 through £70 - prices for this sort of thing vary hugely (and quite often with how much trouble the customer might be !).

Price and availability are just guidelines, our prices change with distribution lists - see the catalog. Stock numbers indicate there is not much call for the part. As yet we have found no further information beyond people offering the part for sale; very little on it curing faults outside .

Copyright G & J Huskinson & MindMachine Associates Ltd 2013, 2015. Some pictures derived from HP User and Service guides. These technical pages do not constitute an offer for sale; just our knowledge at the time of writing. See the catalog. Sales pages on this Web site use cookies to store user information. We also use Google Analytics to track site usage patterns.