We sell spares. We are interested in machines and it’s a market that appeals to us. There is an ethical pleasure in making it possible for people to repair things. Amongst the spares, we also sell printheads for inkjet printers. It would seem a bit crass to stop selling one of the spares people are most likely to want. Inkjet printheads are trouble though.

When an inkjet printer starts giving streaky print and won’t recover, most people read what it says on a few forums, and come to the conclusion it must be the printhead. There is a lot of forum advice out there on inkjet printheads – it’s a hot topic. Lots of people have inkjet printers but it’s a product that always ends in trouble and annoyance.

Read more...

In the absence of any reliable diagnostics the only answer we can give is a slightly evasive, “perhaps”. We might go so far as “probably”. We won’t guarantee satisfaction or your money back; we’d go bust. Printheads are quite expensive and you can’t just try one.

Nobody likes to be told they bought a pig in a poke, but that describes the inkjet printers intended for home and small business use. Some of them look pretty – or at least interesting; many have loads of features. All of them will fail in a way that causes trouble and expense. But if you want colour photos from a printer with a low initial purchase price there isn’t much choice.

Printer Prices

“Printers are all the same” is a phrase we come across. No they aren’t, any more than two cars are the same, such as a Tata Nano and a Jaguar XJ. *

First there is Print Technology:

Read more...

Inkjet technology has historically been the cheap to buy option aimed at students, home and small office use. Simple inkjets are lightly built and cheap to make.

Photographers and people who want wide format use inkjets as well. Big machines are quite different from home printers as we shall see.

Laser printers suit businesses with more than one or two people. Laser print processes are based on rollers and inherently more reliable than inkjet nozzles. Big laser printers give lower running costs too. Printer brands would prefer to sell inkjets; but ALL the big print brands make lasers (or equivalent) and only four make consumer inkjets. Laser printers have their own repertoire of faults but nothing quite so annoying as a duff printhead.

Most printer brands now have fast pagewide inkjets targeted at corporate business. The difference is that these machines don’t make the cost compromises home printers need to sell so cheaply.

Direct Thermal/Thermal Transfer is another common print technology- it uses coated paper as with till rolls or a transferable wax medium as with dye-sub. Both processes are widely used in industry but never caught on in offices and homes.

Dot matrix is much less common than it once was but is still used for rugged reliability and to produce multipart forms.

Price and Features

Printers often give a problem gauging what you are getting. The big sticker on consumer-oriented printers gives a low price and loads of features.

Features cost the brand little or nothing. With a low cost consumer printer; they mainly run on the PC and are often “crapware” – software taster apps aimed at getting upgrade revenue. Print brands sometimes get paid by software houses for distributing it.

Print brands make money from the little stickers on the inks and the printheads. Over the life of a printer most people spend far more on the ink than they ever did on the printer.

It will probably prove difficult to find out how long a printhead lasts. Print brands seem very cagey about giving figures. Thermal printheads will have an upper limit but then a highly variable life.

What Inkjet Printing Is

Inkjet printers deliver a stream of liquid through one or more nozzles. Ink could be anything from a clear varnish to concrete. In the lab, printers have made a heart by printing cells. The nozzle position and amount deposited is computer controlled. There are an enormous range of possibilities. Inkjet machine prices range from £30 to over £3 million.

Read more...

If it’s all so clever why has your printhead failed? Printing colour photographs is technically quite difficult. Cheap printers don’t always use the best technology. Historically the “ThinkJet” and “DeskJet 500” cost £500 and anything that costs much less will have quite a few design compromises. It is surprising what the print industry is delivering at the price and, given the cost constraints, not very surprising it sometimes goes wrong.

Liquid Ink

Liquid ink seems a familiar material. When inkjets originated, right back in the 1950s, fountain pens and bottles of Quink

were the normal way to get writing. Print works still use volumes of liquid ink today – it comes in tins and barrels. Offset litho print is 20 times more common than computer print and much cheaper. But amongst computer printers only chart recorders and pen plotters used liquid ink and they were normally based on pens and too slow. Computer bandprinters, drum printers and dot matrix used ribbons with a grease ink. Fabric ribbon itself has a cost, using liquid directly looked as though it should be cheaper and better.

Read more...

Colour Index Internationallists over 27,000 colourant products. Pigment particles are one or two microns across and tend to give strong, lasting colour but will ultimately settle out. Dyes are either liquids themselves, or much smaller particles a nanometer or so across and “thermal energy” of molecules moving in the liquid prevents them settling. Dyes used to be preferred in inkjets because they are less likely to block the nozzles. Pigments tend to give stronger and more lasting colour. When the ink dries the particles go on imparting colour to whatever they are deposited on. If they dry in or on the print mechanism they congeal and block it.

It is common to see three dye colours (CMY) plus a pigment black (K) ink in cheaper photo/office printers.

The transport vector pushes the colourant around. Tap water is a poor ink vector because it contains minerals and micro-organisms that may be invisible to the eye but capable of blocking a nozzle. Distilled water isn’t so cheap but avoids those problems. Water doesn’t dry sufficiently quickly so most inks are only 40-70% water. Parker Quink incorporated some isopropyl alcohol as a quick drying solvent and that is still true of today’s inkjet inks. Glycol is used to reduce surface tension, lowering viscosity and speeding absorption into paper fibre. Guidance on the main components of an ink is often in the manufacturers MSDS (or COSHH) sheets. The MSDS is only a small help, the minor components such as the actual colourant, binder, dispersants, surfactants, penetrants, humectants, biocides, metal chelating agents and pH correctors are usually listed as “trade secret”.

Ink used to be made from oak galls, iron and vinegar, which sounds simple but gave a complicated mix of fats, acids and dyes. Modern inks are careful assembly of many things. The objective is to stay liquid in the pen and then turn dry instantly on the page – that is a hard ask. Other things the ink has to achieve are strong colour, colourfastness and water resistance. Printer ink particularly needs to avoid “bleeding” horizontally along paper grains – in particular black must not intrude into yellow. That can be achieved by making the black acid and the yellow alkaline so they react and halt on contact. Ink chemistry is far from simple. Get the chemistry wrong and the printhead clogs.

Thinkjet picture from Wikipedia

Thinkjet picture from WikipediaThinkjet: 12 nozzle head offered a small advantage over dot matrix

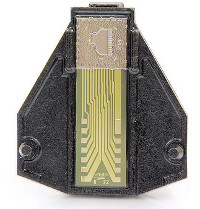

Early Thinkjet Printhead, HP 51604A. 3ml and about 750,000 characters of print. Entirely disposable, with a street price today around £11. The Thinkjet head is still used in industry for its simplicity, reliability and easy replacement.

Early Thinkjet Printhead, HP 51604A. 3ml and about 750,000 characters of print. Entirely disposable, with a street price today around £11. The Thinkjet head is still used in industry for its simplicity, reliability and easy replacement.Inkjet Printhead Types

A lot of early inkjets used either

- a continuous stream of droplets steered by electrostatic plates

- pressure pumps and solenoid valves to produce dot-on-demand

Both approaches work well on factory production lines. Neither suit an office or domestic environment since compressors, pumps, solenoid valves and flying ink drops don’t fit too well with upholstery and polish.

Thermal Printheads

The idea of thermal inkjet printheads was discovered in the late 1970s by HP and Canon; it seems to be a case of simultaneous invention

. Both used the idea to make quiet battery powered substitutes for dot-matrix printers – the ThinkJet launched in 1984 and BubbleJet in 1985.

Read more...

The heart of an inkjet printer is the printhead. The printhead has a column of narrow nozzles that normally hold ink in by capillary action. A disturbance in the nozzle breaks the meniscus of liquid and ejects a droplet.

Canon and HP discovered that a little resistive heater behind the nozzle would create a momentary bubble in the ink and eject a droplet. Early printers had just 12 fairly large nozzles, so print quality wasn’t great. The printheads also tended to dry out and block, but thermal printheads could be made cheaply and treated as disposable. Most of HP’s early printers use a cartridge with an integral printhead; so that when the cartridge is empty you automatically get a new head. (On the other hand, if the head fails but the ink is not finished, some gets wasted.)

Piezoelectric Printheads

Epson had built a business making dot-matrix printers and they took a different approach. Siemens (and others) had made printers using piezoelectric ejectors – crystals that change shape in response to an electrical field.

Read more...

A page is potentially covered in several million dots. To get printing at a reasonable speed the printhead needs a column of nozzles rather than just one. Each nozzle can fire thousands of times per second but ink droplets take microseconds to form and detach so there is a limit on what can be done. Early printers used the one or two dozen nozzles to form a line of text, Epson could describe their 24 nozzle head as “letter quality”.

Laser printers were the big thing of the 1980s and HP and Canon as computer and copier companies built an alliance that saw HP take over half the market and Canon another 20% or more. Inkjets were a niche market by comparison.

From Epson history documents. The Epson stylus Color had a 64 nozzle black head for speed and 3 columns of 16 colour nozzles. Print resolution of 720dpi meant that photographs had reasonable half-tones.

From Epson history documents. The Epson stylus Color had a 64 nozzle black head for speed and 3 columns of 16 colour nozzles. Print resolution of 720dpi meant that photographs had reasonable half-tones.In Japan it was sold as the MJ-700V2C.

From Epson history documents. Where the Stylus Color had a role as a fast text printer the Stylus Photo launched in 1997 aimed at the growing photographic market. It offered just 32 nozzles for black, but also 32 each for five other colours: Cyan, Light Cyan, Magenta, Light Magenta and Yellow. The five colours enhance the colour gamut (range). Nozzles fired at 14.5kHz – double what the Stylus Color used, so the printer was faster.

From Epson history documents. Where the Stylus Color had a role as a fast text printer the Stylus Photo launched in 1997 aimed at the growing photographic market. It offered just 32 nozzles for black, but also 32 each for five other colours: Cyan, Light Cyan, Magenta, Light Magenta and Yellow. The five colours enhance the colour gamut (range). Nozzles fired at 14.5kHz – double what the Stylus Color used, so the printer was faster.Colour and A Thousand Nozzles

Inkjets came to the fore as digital cameras took off in the mid 1990s.

Digital cameras are one of the many computing ideas that emerge left-field, people don’t foresee it happening. Kodak was amongst the first to market with the low-cost DC20 camera but they, Polaroid, Fujifilm and the other camera companies didn’t realise it could destroy the film business. Kodak was once one of the worlds biggest companies and they tried to get into the inkjet business but by 2012 the spiralling costs of inkjet development and decline in film bankrupted them.

Read more...

Colour photographs obviously begged the question of colour print. Dot matrix colour is crude and slow. Copiers and laser printers need four mechanisms. Thermal transfer and dye-sub print works well but wastes half the colourant. Making a colour inkjet just needs four nozzles and cartridges in a line – and furthermore the output can be made to just about match all but the best photographic prints.

Epson took something of a lead in 1994 with the “Epson Stylus Color” piezo inkjet printers. The Epson Stylus series got a head start in photographic work and they were able to raise cartridge prices on the brand’s strength.

Canon had some strength because their origins were in photography. Canon and HP may have cooperated in laser printers but were rivals in inkjet. Both introduced a line-up of cameras and colour inkjet printers. HP created a sub-brand for both cameras and printers called “PhotoSmart”.

Colour Print Problem

Colour photography is a hard target for computer printers because our eyes see an indefinite range of hues and luminosities. Most digital print processes are binary, there either is a dot of ink, or not. Half measures such as small dots or grey dots are difficult, so the printer can’t vary the hue or intensity of a dot.

Read more...

Colour print uses four inks, Cyan, Magenta, Yellow and Black. The CMY combination gives brighter colours than could be achieved with red, green and blue. However mixing three colours only gives eight colours including white and a grunge-brown – hence the need for printers to also have a black cartridge.

Computer printers can get over their limitations by shrinking the dots, ideally below the threshold of human visibility. There isn’t complete agreement on what that limit is, the offset-litho industry generally uses 300 dpi but they do change the size of the dots. Dots 0.02 mm across (20 micrometers or 1200 dpi ) are a quarter the width and a sixteenth the area of the finest pen and individually invisible. Laser printers hit technical limitations between 1200 and 2400 dpi and stop there. Inkjets sometimes claim 9,600 dpi which would be a dot 2 microns across. Hence, inkjets can produce better photographs than laser printers.

The greens and blues of the sea are then made up from “dither patterns” of cyan/yellow, cyan/magenta. With modern micro-manufacturing techniques, inkjet nozzles 8 microns wide ejecting a 1 picolitre drop are possible. However that does mean the nozzle is less than a hair’s thickness so it is liable to block at any impurity in the ink.

Putting Dots On a Page

An A4 page at 8×11 inches printed at 1200 dpi contains 126,720,000 points or with 4 colours potentially half a billion dots.

Read more...

An inket page might actually contain a lot more than that because 1200 dpi is a 20 micron dot. Many inkjets use picolitre drops that are likely to be 12 microns across on the page (dot gain) – so there will be four or five dots to give cover and often two colours overlapping – possibly 5 billion drops on a photographic page.

64 megabytes of memory is nothing for today’s computers which typically come with several gigabytes. It was significant until about 2008 though. Luckily for inkjet makers they didn’t have to give the printer all that memory, the inkjet can stop at the end of a line and wait for the computer to do the work. Laser printers couldn’t stop and needed both memory and processor power. That was one reason they were more expensive.

If one nozzle achieves 20kHz it looks as though it will need 25,344 nozzles to print a 1200 dpi page in a second. That has now become practical but only quite recently.

It isn’t quite that simple because dots from a nozzle are approximately circular. Only approximately, because the printhead is moving so there is a tendency for then to be oval or tear-drop shaped. If the dots don’t join up solid colours will be lighter than expected. To overcome this the printer might use nozzles closer spaced, with overlapping domains on the page. Alternatively it might infill on the next pass of the head. After infilling, overlapping dots will be darker.

Actually there aren’t just 8 possible colours because overprinting magenta on cyan gives a different blue to cyan on magenta. Overprinting one, waiting until it dries and then overprinting gives less mixing but less colour-bleed as well.

InkJet software (preferably in the printer, probably in the computer) should do some picture processing to determine what the effects of the colour range available, overprinting, dot shape, overlap and so on, will have on the printed product. It might use different techniques for text and images, it might distinguish between sky, woodland and faces to get a best effect. Software can enhance what an inkjet does.

There is another advantage to having all those overlapping nozzles. If one fails, and the printer can detect it, it can compensate.

Drop Size and Nozzle Count

Using very small droplets creates a few difficulties:

- They must emerge from the nozzles very quickly. Achievable frequencies range from about 10 to 100 kHz (drops per second) and there is a non-linear relationship between frequency, droplet size and power used.

- To get the print speed up on a photograph a printhead ideally requires hundreds or even thousands of nozzles rather than a dozen.

Read more...

Printheads are complex to make but the four (or five) companies still competing in the consumer inkjet game seem to believe they can make money. Photographic printing can be made better by incorporating more inks giving a wider colour gamut (the customer gets better photos but buys more cartridges). Inkjets have tended to be slow and too erratic to be trusted as office printers but a new generation with nozzle counts in the tens of thousands arranged across the page can print as fast as laser printers. Improved understanding of droplet formation and separation allow the heads to stay clean and polymer inks dry almost instantly on the page. Better service stations keep the heads clean and restore ink flow.

Development costs are high though. Kodak spent over three billion dollars to develop inkjet technology and critics liked the product but they couldn’t take sufficient market share. Lexmark withdrew from making inkjets a couple of years ago; they struggled with reliability. Oki had a brief experiment with the idea and stuck to electrophotography and dot matrix. Dell has withdrawn from the print market altogether and in Autumn 2016 Samsung sold their printer business to HP.

If you think inks are rip-off prices, the companies aren’t making much from it in the end. And the future for conventional print looks limited. As screens get ubiquitous, home and office printing will never quite die away, but it will decline.

Strangely though, those low cost screens may be printed by inkjets. Inkjets with organic semiconductor and conductive inks are beginning to make the next generation of electronic devices. These are not consumer inkjets.

This HP tricolour cartridge has the printhead built in. Printers using this technique cost more to run but have the advantage of simplicity. When it goes wrong, replace it. There is little risk to using compatible inks as there are not many parts of the printer to damage.

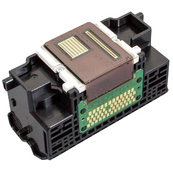

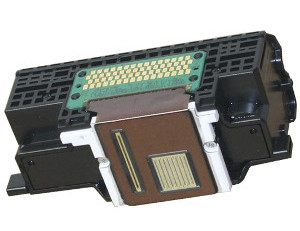

This HP tricolour cartridge has the printhead built in. Printers using this technique cost more to run but have the advantage of simplicity. When it goes wrong, replace it. There is little risk to using compatible inks as there are not many parts of the printer to damage. Canon PIXMA MG6120 printhead QY6-0078.

Canon PIXMA MG6120 printhead QY6-0078.Note the black head has a wide swath and the six colours share one narrower head.

HP Photosmart printhead for 7520, B8550, B8553, etc seen from the cartridge side.

HP Photosmart printhead for 7520, B8550, B8553, etc seen from the cartridge side.Again the black head has a wide swath, evidenced by the need for a large ink cartridge filter. There are three colours, and a photo-black.

These are cartridge-on-carriage models; that limits the ink cartridge size.

The Canon PF-03 printhead for their wide-body printers costs more than most consumer inkjet printers.

New printheads are simply part of the expected cost of running a printer.

Inkjet printhead life tends to be rather unpredictable and people don’t like that.

Why Printheads Fail

Inkjet printheads fail when something gets trapped in the fine nozzle. Usually that will be the ink. It could be congealed pigment. It could also be an impurity within the ink, a fragment of something in the colourant or the many additional substances. It could be something biological growing in the ink, like a yeast or algae. Air bubbles are a particular enemy to inkjets, they are difficult to dislodge. Dust can also transfer from the paper onto a printhead and flow patterns can carry it into nozzles. The flow patterns around inkjet nozzles can be complex.

Read more...

A widespread problem is thought to be paper-strike. Paper may simply catch the printhead a glancing blow as it loads. If paper jams then the coating of chalk and kaolin meant to absorb ink is up against the nozzles of the head and when you pull the wreckage out it smears across the heads. Fibres are 20-40 microns across, kaolin 2-5 microns. Nozzles get blocked.

Then there is the service station. The purpose of the service station is to take minor failures and fix them. To do this the surface station is usually based on a wiper blade and a spittoon. The printhead nozzle attempts to spit ink droplets whilst the wiper blade goes back and forth removing any obstruction that emerges onto the surface. A certain amount of ink gets used. The service station might also incorporate the printhead parking caps – and they might be connected to a purge pump that will try to remove airlocks. HP’s pagewidth printer service station has a web of material for wiping the printheads. Service stations range from nothing to elaborate.

Incidentally, if the power fails whilst the printer is running it won’t be able to cap the printheads and if the condition lasts they will dry out. There isn’t a lot you can do as pushing the printhead home won’t necessarily raise the caps. Power outages rarely last – but it’s a point to note.

Recovering Printheads

If your printer has low cost cartridges with an integrated ink tank and printhead the causes are probably unimportant. Run the cleaning cycle and the deep-clean cycle. Read the user guide. Look of the manufacturer’s website and forums If that doesn’t work try standing the printhead nose down in water overnight – there isn’t much to lose. Prepare to buy a new cartridge.

Read more...

If your printer has separate ink tank and printhead it’s a bit more problematic. Separate heads are usually more complicated and costly to make – that is why they aren’t disposable. The main reason for the expense is to give photographic performance. Another is that brands have taken to making a whole set of half-a dozen printheads as one unit. When you replace the head it will also use quite a bit of ink as the reservoirs in the new head fill.

Experience suggests that

- The “permanent” thermal printhead of the kind used in Canon and HP printers lasts through about four to ten changes of cartridge. It is model dependent, of course. Printheads could have the longer life if the printer is frequently used because the inks don’t get so much opportunity to dry out. When an HP or Canon inkjet printer fails, changing the printhead works most of the time. Thermal printheads are probably most likely to die through blockage. Other causes are thermal stress cracking the resistor, as it goes on and off it swings from 20 to beyond 200 centigrade thousands of times per second and as the temperature changes a wave of pressure then vacuum passes over it. Then there is resistor burn-out, scale buildup (called kogation) and ink attack on printhead components are other possible causes. Thermal printheads can last some time but they will fail.

- Piezoelectric printheads used in Epson and Brother printers are intended to last the life of the printer. It would be more correct to say that they define the life of the low cost consumer printers as you almost certainly won’t want to buy a printhead and pay the service charge to have it professionally fitted. Piezo printheads don’t have the thermal stress, burnout and kogation issues. However the piezo material is likely to denature over time so it has a long but not infinite life and things like blockage and acid attack are possible. Air blocks seem to be a particular problem for piezo printheads; once the flow is stopped by a bubble it is difficult to restart.

Most things wear out through use. Some inkjet printheads will wear out after a given amount of use. Liquid passing through the head doesn’t create much wear in consumer inkjets but continual hot-cold cycles do. Another problem in thermal printheads is “kogation” – salts from the liquid gathering on the resistors that eject ink.

Counter-intuitively, inkjet printheads will also fail due to not using them. If they are not adequately protected by the service station, ink will dry in the hair-thin nozzles and on the service station itself. It may be this latter that is the greater problem because then the seal will not work well and so the problem worsens.

Printheads may last longer if the printer is left turned on. Some printers have software which will periodically shuffle the printheads to keep them moist and keep the air-seal intact. Which printers do what we couldn’t say: your user manual might (but probably not). It’s a matter of what the printer firmware tells it to do. There are simply too many varieties of printer for us to keep track.

With domestic inkjets you definitely should print in both black and colour a couple of times per week to keep wet ink present. No, we aren’t just saying that because we sell ink (there is little profit in brand original inks – the brands keep nearly all for themselves).

Some other pointers:

- Keep inkjet printers out of areas you know to be dusty – and away from fans and open windows.

- Don’t put paper in when it has been exposed to dust. You may need to be careful about paper quality as cheap office paper cut with a saw sometimes carries quite a lot of dust with it. Printer manufacturers like to sell special but expensive inkjet paper and because of the cost people keep it to one side. Keep it in a sealed plastic bag.

- If paper is left in the printer and the printer doesn’t have a drawer or dust flap then take the top sheet off before using the printer – otherwise the paper carries dust from the room into the machine.

- Inkjet printers are really creatures of the cool, dank cave. Keep them out of the sun and away from radiators and air conditioners because both of those will dry the innards.

If you put an inkjet printer away in a cupboard for six months it would be surprising if the printheads still worked when you take it out. If you use it every day then you will take 183 pages worth of ink and the wiper and head-seal caps will be a bit more worn but at least the printhead has a chance of surviving.

Printers on Holiday

If you are going on a long holiday you can’t really take the printer with you. The printer won’t get lonely, it will just gradually wither and dry up.

Read more...

HP used to make a little “humidor” for putting part used cartridges in – it went with the DeskJet C600 (we think) and was part number C2184-60026. It had a little clip to secure the cartridge with the nozzle on a pad. Alas, we can find no trace of it in HP recent literature – but a bit of web research suggests it didn’t work well anyway. HP have a US design patent on cartridge humidors dated 2002. (US D479853).

Cartridges come in foil sealed bags with a seal strip over the nose. That is difficult to imitate; obviously you cant put sellotape over the nozzle sticky side down. You could make an area of blank tape by putting an inch of sellotape sticky side down on the inside and putting that over the nozzle. Most Sellotape seems hygroscopic though, so perhaps it’s the wrong material?

Manufacturer: usually understood as a business that has factories, can make parts and assemble products. Manufacturers have always subcontracted though. | Brand: a business with a recognised logo, name and marketing. Copyrights, patents, secret proprietary procedures and non-disclosure agreements with sub-contractors. Brands may own some factories for critical products. HP has its own printhead factory. |

Original, OEM or “printer brand” cartridges. – Cartridges carrying the same brand logo as your printer -. HP and Canon both make inkjet printers. (So far as we know Canon doesn’t make them for HP as they do with laser printers, they are made under contract by Flextronics etc).

Refill cartridges are simply those that have been refilled with ink. Integrated inkjet printheads will typically last two or three times longer than the ink they are initially charged with. Epson cartridges are just tanks with a killer chip.

Remanufactured cartridges exist for laser printers. The part of an inkjet cartridge that would need remanufacture is the printhead, but there are few (if any) factories that could supply such a thing.

Compatible cartridges have been made new to fit into the printer. Compatible cartridges exist in huge numbers for any sort of inkjet where the cartridge is only an ink-tank. If they exactly imitate the brand original they may be illegal because the brand will have (dubiously valid) patents on its plastic box and less arguable copyright. Many of the important patents on laser printers have expired and that is one reason the brands prefer inkjet technology. Their R&D investment isn’t simply appropriated by others.

Counterfeit cartridges are either of the above packaged and marked as though made by the brand.

The printer brands run a fairly continual campaign of court action against people making and selling compatible and counterfeit ink.

Your problem as a buyer is that you can have very little idea of the provenance of that “compatible” ink and whether it could wreck your printhead.

Given the brand-name legal campaign against them, some of the compatible vendors don’t expect to be in business for long. They won’t spend much on R&D. An approach we note is to recruit someone with an inside track on what the brands do, create a name, push product through Adwords and close down just before the court judgement. Re-appear a few months later under a new name.

Branded Ink Cartridges

There are four sizeable consumer- oriented inkjet printer manufacturers: Brother, Canon, Epson and HP. There is a certain amount of competition for business even, we might suggest, a price war. With only four corporates playing they clearly monitor one another at every step.

If you have just paid £199 for a printer it may not be evident that it was “cheap”, but it is. Printers are largely mechanical parts. Other mechanical things like washing machines, refrigerators, bicycles and cars tend to go up in price. Printers have fallen in price. The HP DeskJet 500 cost over £500 in 1993. A rough equivalent today would cost under £50.

Cartridges Subsidise Printers

Cartridge sales cross subsidise printer prices. Printer brands use low priced printers to gain market share. They all have much the same strategy. The main weapon is to push the price of printers down, then make that back up on cartridge sales. Printer brands push the price of ink cartridges as high as possible to compensate for their low revenues from printers.

Read more...

Brands don’t like to admit this, and will come out with phrases like “we make a profit on everything we do”. It would be difficult to prove otherwise because costs are opaque. There is clearly an R&D cost to launching new models all the time. But, rather rudely, we would suggest that printers aren’t getting dramatically better. Inkjets have got faster and less unreliable – and may be able to challenge laser printing for cost effectiveness. But printing in general is not coming on leaps and bounds. The core improvement most users want is LOWER COST.

Printers have not generally got cheaper to use. Printers have acquired copier-scanner mechanisms and a nicer control panel, WiFi and Near-Field print. Some of them have OCR and document management features. Printers are trying to be indispensable. None of those features are really needed in a printer. Printers are full of things the DeskJet 500 lacked – if you wanted scan copy and fax features you bought the relevant part: scanner; fax-modem, OCR software. Printers themselves are the same old thing dressed in new clothes.

The problem with the cheap printer / expensive cartridge approach is that a cartridge is essentially a cheap plastic box with a few millilitres of ink in and that attracts a host of imitators, refill and compatible makers to the market.

With every office and about 80% of households in Europe and the US having a printer of some kind the market for cartridges is large. A rough guess at a worldwide figure for cartridge sales of all types is in excess 350 million per year.

Read more...

Not surprisingly there are hundreds of manufacturers trying to muscle in on the ink market.

We know from contacts that Epson cartridge that normally sell for £9 can be bought in container-loads from China for under a dollar each and sold in the UK for £6. A very healthy mark up and worth some trouble. Or rather, they can until Epson’s lawyers catch up.

There are also ink refill kits which provide a bottle of ink, a syringe and one or two other plastic gizmos that may help to get ink flowing. Businesses selling these tend to sell through eBay and stay small.

Continuous ink systems deliver ink from bottles through into the printheads via delivery pipework. This off-axis delivery is actually what is found in most larger printers. The problem with a retrofit kit is that the printer was not designed for it – quite the contrary so now the printer brand definitely won’t honour warranty or take any support calls.

Let’s be clear. If you do a lot of printing you can save a fortune using a continuous ink system (CIS). But you have to be technically inclined, not mind the printer running with its top off, and willing to take the knock when a bad batch of ink wrecks the printhead.

Epson found the CIS systems sufficiently troubling that they have taken the “can’t beat em, join em” attitude and launched a printer series that includes ink tanks. Obviously it isn’t as cheap as buying litre bottles of unbranded ink.

We stopped selling compatible cartridges and continuous ink systems for inkjets ten years ago because there were far too many support calls.

There aren’t actually hundreds of colourant and ink manufacturers: Coates, Flint, Toyo, VanSon – they seem to stay away from the fray over compatible inks. Presumably they sell to whoever asks but don’t offend the major print brands.

Brands keep the compatible inks at bay by design churn; printer designs are continually changing in minor ways. The easiest is to put a “killer chip” on the cartridge; the printer must sense that chip or it won’t work. When most of the ink is used the printer “kills” the chip so the cartridge won’t work if it is refilled. The dialogue between printer and chip is encrypted so that chip resetters won’t always work. There is a small industry making chip resetters and clone chips.

We are firm believers in using manufacturers original inks in the current generation of inkjet printers. Ink formulation is complex as suggested above and only the brand is likely to be able to get composition, purity and colour right.

If you use anything other than the brand ink you have very little idea of its provenance. For instance, it may contain isopropyl or an equivalent volatile component that will attack the plastic or the glues in the printhead. Likewise with acids used to bind to the paper. Change cartridge from original to compatible – or the other way round and it is possible for the ink to coagulate in the printhead.

We have asked refill and “compatible” manufacturers about their processes and have yet to find one that can give a satisfactory account. Furthermore they provide no documentation and change what they do on a sixpence to make more money. Most actually have no control over ink composition, they are buying it in from Asia in bottles where they are uncertain of its true provenance. Compatible ink is certainly much cheaper to buy but in our experience it will cause printhead Trouble!.

There is obviously a judgement call here. Brand original ink is expensive. So are some printheads:

- If you have a cartridge with an integral printhead then there is no harm trying to refill it as nothing much is lost when it doesn’t work. We used to refill the old DeskJet 500 cartridges with Quink and quite often it worked! It almost certainly won’t work well with recent printheads because they have many more and much finer nozzles. To be honest, we’ve never bothered to try refilling in a decade. (We heed our own advice and use a mono laser printer).

- If you have an HP printer with separate printheads then the savings in ink might justify trouble with the printheads. If you are a keen experimenter you can always try cleaning out the printhead – more below. (After all, you have nothing to lose).

- If you have a one-piece 12-colour printhead costing over £100+vat (as used in some of the Canon devices) we would advise steering clear of compatible inks. One bad cartridge will wreck that printhead. But you won’t be absolutely certain what caused the problem and will fiddle around wasting ink and trying to rescue that expensive printer.

Printhead Types

There are two broad types of printhead: thermal and piezoelectric.

HP and Canon use thermal printheads. A thermal printhead uses a small resistor in the nozzle to create a vapour bubble by boiling that forces a droplet out. Ultimately some resistors are likely to fail because of the hot-cold cycles so that the printer is designed with the idea that the printhead will be changed. Changing an HP or Canon printhead should work. We have good experience with HP printers. Canon printer heads are often more complex, with up to a dozen inks, so we are a bit more sceptical

We will usually advise against changing Epson or Brother printheads – these are piezoelectric designs. The ink is ejected by movement of a crystal of “PZT” which could last forever in principle. Piezo printheads are complex to make, expensive to buy and normally need special setup software that you will not easily be able to get. You will get no support from the print brands for changing an inkjet printhead if you are not an authorised dealer – and probably not if you are.

Inkjet printheads have a simple problem. To get the photographic quality inkjet buyers typically demand needs thousands of dots per inch. Translated into a printhead that means hundreds or thousands of nozzles about 8-10 microns across – far less than the diameter of a typical hair. The nozzles are only visible under a microscope. Any impurity in the ink or anything from the paper that gets pushed into a nozzle will cause a blockage. Blockage will often be fatal to the nozzle in a thermal printhead, it will overheat, carbonise the blockage and burn out. Piezo printhead innards can’t move vigorously enough to shift a blockage.

Counterfeit Printheads

Compatible and counterfeit printheads are unknown. It is almost impossible.

Read more...

Vendors often put “Genuine Canon Printhead” and other such things on products – we sometimes do it ourselves. No harm in reassuring the customer. Counterfeit printheads are almost unknown and in November 2016 a search in Google for “counterfeit printhead” turned up one person in the US claiming on an HP forum that he’d been sold one on eBay.

Fake printheads are possible, but to work at all they would be recycled – and as we discuss below getting one that has failed to work again is difficult. A printhead would have to be incredibly well tested, clean and dry before it could be put into stock with any hope of working – so eBay vendors trying to sell them will get poor ratings.

Making new compatibles would be a multi-million dollar project. If you can make fake printheads go the whole way and make the printers too. Start your own printer company and profit from ink sales. If anyone is making fake printheads they are nuts; stick to fake watches.

Printhead Return

Printheads come in sealed packs. Once you open the pack you own the head.

Read more...

Diagnosing inkjet faults is problematic. There are too many different designs, a new batch every month or so from the four companies that make them as they jockey for market appeal. For any one printer there is no great mass of experience out there – it’s all shifting sand.

For the most part there are no manuals and no diagnostics. You can’t have a “take it home and try it” service. Once a printhead has been used it won’t keep because the ink will dry out – even if you wash it out or keep it in a box with a damp cloth. Printheads cannot be cleaned and re-used. Printheads can’t even necessarily be swapped to another printer to test. Factories test printheads before despatch in a diagnostic jig that probably only addresses the electronics – it could conceivably fire distilled water or isopropyl. Printhead factories are very secretive about their processes.

New printheads do come with a warranty – usually 90 days or a “fair use” limit. If the printhead doesn’t work and you return it as “faulty” the manufacturer may test it and refund or replace. They may not. If they assert it was not faulty you won’t get a refund but will be liable for the return carriage. But of course it still won’t work because the fault lies in the printer, not the printhead. We haven’t found the brands to be mean about returns but it would be remiss not to point out that they could be and that policies change all the time. The reason brands won’t deal with the public directly is that they don’t want the hassle.

Faults that Look Like a Printhead Problem

Other than breakages, almost every fault an inkjet can develop is likely to give streaky print and look like it is the printhead. Things that could be at fault when an inkjet does not print properly are the cartridge and head connectors, cartridge seating and alignment, the cartridge is out of ink but the killer chip says not, service-station wiper blade and purge pump, trailing cables, feed pipes and the electronics themselves.

The service station for the HP DesignJet T2300. It’s a substantial mechanism and at nearly £200 costs more than many home inkjet printers. The machines it fits in cost £2,000 and up.

The service station for the HP DesignJet T2300. It’s a substantial mechanism and at nearly £200 costs more than many home inkjet printers. The machines it fits in cost £2,000 and up.Service Station

The service station is intended to cap the printheads when they are not in use, clean the printhead at startup and intermittently during print-jobs. It usually has four main subsections, the wiper blade, cartridge cups, purge pump, possibly a pressure pump and almost certainly an ink absorber. In expensive printers these may all be separate items and there may be a droplet detector as well.

Read more...

A worn wiper blade will commonly cause some nozzles to fail and then things will get progressively worse. The wiper blade functions somewhat like a windscreen wiper, it is intended to make a clean sharp sweep across the glassy front of the head. It will encounter some wear from adhesions. It is also likely to be worn by the pits where the nozzles are. It will have a limited life.

Most service stations also have some sort of vacuum pump to pull ink through during the purge or prime process. Some printers also have a pump to feed air pressure to the cartridges to force ink out. Pump design varies hugely but it is clearly possible for gaskets to wear or bellows to develop a hole.

When the printer is not in use for a few minutes it will usually cap its printhead. Caps are made of a soft silicone rubber or perhaps polypropylene. Choice of materials in a cheap machine will be based on cost not longevity. Caps will wear out, develop an air-leak and make the printheads more likely to dry out.

A typical wiper blade, this one is for an Epson Stylus Pro. They are available for a couple of pounds – largely the logistics cost. Changing one is messy though.

A typical wiper blade, this one is for an Epson Stylus Pro. They are available for a couple of pounds – largely the logistics cost. Changing one is messy though.Service stations with their various components can be complex assemblies. Manufacturers cut corners to get the price of low cost printers down. Wear to the rubber components is inevitable. Mechanical failures happen. Big professional printers (£2000 class) often have complete service stations and even parts like wiper blades available as spares. Printers sold for home and small business use have a greatly simplified service station and neither it, nor its component parts, are commonly available.

One failure mode that can come from the service station is if the ducts leading from the caps to the ink absorber are blocked. Then when the printer raises the cap onto the head, it forces air (which cannot escape down the blocked ducts) into the nozzles – very much not what is wanted particularly with a piezoelectric head but also giving a potential overheat and burnout in a thermal head.

Another possibility in a printer is the “pillar of crud”. Ink builds up on the absorber and forms a pillar in the “spittoon” area which the printhead then runs into.

If the service station mechanisms are faulty then replacing the printhead may solve the problem temporarily because a new printhead needs purging but not cleaning. That needn’t last – a bad scraper blade remains a liability. If the part was not designed to be removable or it there are no spares that is effectively the end of the printer!

The DesignJet 130 carriage cable was made available – but it is “captive” as part of the carriage so changing it isn’t easy. Spare trailing cables aren’t usually available for consumer inkjets.

The DesignJet 130 carriage cable was made available – but it is “captive” as part of the carriage so changing it isn’t easy. Spare trailing cables aren’t usually available for consumer inkjets.Trailing Cable

Trailing cables are necessary in moving-head printers to carry power and data to what is sometimes called the intimate electronics

in the printhead. Most modern inkjet printers use several serial data streams carried to a demultiplexer in the head which then addresses the power transistors driving hundreds or thousands of nozzles. The trailing cable itself is usually a plastic ribbon about 15 – 20 inches long depending on whether the printer is A4, A3 or wider containing something between 20 and 40 parallel metal traces – it is sometimes called an FFC (Flexible Flat Cable). Quite often there are two parallel cables because a set of colour printheads need a lot of signals.

Read more...

Trailing cables continually flex as the print carriage moves. Any plastic or metal that does this will develop hairline fractures. Initially the result might be intermittent loss of one of the serial channels so that some nozzles don’t work – and perhaps only when the cable is maximally flexed at one side of the page. Fracture lines can sometimes be seen in transparent copper-coloured trailing cable but the more common white material shows nothing on the surface. The test with old dot-matrix cables was to “bell it out” – test for continuity with a circuit that rings on each contact. The cables to inkjet heads usually have lots of conductors very closely spaced and there may be no socket at the ends of the cable, so testing continuity manually is nearly impossible.

To get reliability during warranty there is an incentive for manufacturers to make the cable unchangeable by soldering it down. If there is a trailing cable socket poor seating into the electronics can reduce reliability. So manufacturers usually fit the FCC into a socket on the printer electronics board but sometimes they solder it to the board in the print-carriage.

Ink Supply

Larger industrial quality inkjet printers frequently have flexible pipes carrying ink from the base to the carriage. The ink supply station can be quite complex with a pump and cartridge sensors. Canon have even been known to put LEDs in the cartridges to verify when they have been correctly inserted and identified.

Ink supply tubes are generally made of a silicone / polythene / polypropylene material, this will also flex and will ultimately fracture. Flexible pipes are also prone to air-bubbles developed from ink that was not properly de-aerated in the factory and from biological contamination again caused by bad inks. Using anything other than the manufacturers brand ink can give these problems. It may be possible to shift an air lock by squeezing the pipe with finger pressure. Another possibility is to disconnect the pipe and use a syringe to suck the airlock through followed by good ink. Our experience is that it is difficult to remove air-locks in the feed pipes and if the real problem is the nozzle cap or purge pump it may work then fail again.

Epson 2131352/2113688 etc TM-88IV main board. Part of a receipt printer. At £270 upwards receipt printers are regarded as worth the effort of repair and can be straight-forward but you need to watch out for board and firmware revisions.

Epson 2131352/2113688 etc TM-88IV main board. Part of a receipt printer. At £270 upwards receipt printers are regarded as worth the effort of repair and can be straight-forward but you need to watch out for board and firmware revisions.Electronics

The drive electronics is also capable of failure – but it isn’t likely. Inkjet printers are built to a low cost so there is usually just one main circuit board that holds the processor, communications, motor and printhead driver chip. Low cost is not usually an issue with electronics unless you plan to operate in the Antarctic.

Read more...

We suspect the most likely cause of electronic failure is static-electric discharge from people in polyester clothes in dry environments trying to fix printers! If you don’t have an anti-static kit, touch a radiator or something earthed to make sure you carry no charge immediately before going near the printer electronic contacts. If you are getting static jolts in your work environment then touching the printer will damage it. (It will damage other computer equipment as well – so get some anti-static spray or a ground-strap).

People commonly assume that electronics have gone wrong in a printer. Electronic parts (other than power supplies) in a printer are not very prone to failure. Electronic circuits in a printer do not encounter much unexpected stress and certainly not in a way that would cause streaky or no print. If there are control panel lights and motor action then the electronics is probably all OK. However it’s a moot point because new main boards for inkjets are either not available as spares, or only at extortionate prices and/or perhaps only on eBay.

Incidentally, as a commercial technician it is unlikely that you can strip an inkjet printer, replace the electronics (run whatever setup software might be needed) and rebuild and re-align it for less than the cost of a new printer.

Inkjets aren’t made to be serviced because there is an assumption that no professional will try. They don’t come apart easily. There are no diagnostics. There are few spares. There are usually no service manuals.

Diagnostics

Many if not all inkjet printers do have factory diagnostics which could in principle give you information about what precisely has failed. HP and the other manufacturers have “secret menus” that reveal what dates parts were manufactured, warranty type, usage figures, whether you have used a non-HP cartridge and so forth.

This though is of very limited practical use because there are no service manuals for most inkjets. Even if there are service manuals they do not give any support for using the diagnostic information or even tell you how to access it. The tests are there for factory and warranty triage purposes. Electronic items have a facility called the JTAG boundary test; manufacturers scarcely ever give information on how to use it.

Manuals and Spares

Products usually come with a user guide. With inkjet printers they tell you how to load paper, how to insert the cartridges and what the flashing lights on the control panel mean; very little else. All technical information is carefully purged from user-space either because

- It would “scare” the readers. Inkjet printers are often sold to people who don’t really want to know anything about computers.

- Or because it might empower them. Once the the printer is a couple of years old the brands would prefer you to buy a new one.

HP Inkjet Service

Many products also have a service guide. In fact they are more or less required to have a factory setup, test, warranty service and triage guide. In HP’s case there are service manuals for the DesignJet series. There are no service manuals available to the public or the trade for any of the low cost inkjets. There were some in the early days for printers like the CP1700 series but what happens is that there has to be an engineering demand to make producing the manuals worthwhile – and if the value of the printer doesn’t pay for the engineer there is no service manual. The only spares available are usually the printhead and the power adapter. No other spare is available – not even the tray flaps which break off, the cartridge clamps which often break or the paper pickup rollers.

Read more...

Pickup rollers are readily available for HP laser printers – but not inkjets. We suspect that the pickup rollers are not available for HP inkjet printers because (frankly) no inkjet ever lasts long enough to wear them out.

The service component that often is available is a complete printer chassis – possibly in a brown box without consumables or the CD. Initially these are cheaper than a new printer. There is a problem that the initial price of an inkjet is often double it’s realistic street price and that is double its end-of-line hurry-while-stocks-last disposal price – so the stripped down replacement spare might be twice the price of a brand new printer with consumables and a year’s warranty.

Canon Inkjet Service

Canon printers do sometimes have service manuals available and may even list spares. It may not be easy to find the manuals because Canon don’t make them freely available so it’s a hard Google search to find them at times. The situation is no better though because few spares cost less than £60 and that means no-one stocks them.

Brother Inkjet Service

Brother printers often do have manuals and some spares. Some of Brother’s inkjet service manuals contain an excellent explanation of how the printer works so if you are technically inclined they are worth a look.

However the fault usually is the printhead and it costs nearly as much as the printer, requires a setup disk and no – they won’t supply that software.

Same issue with Epson; but spares supply can take so long you will have bought another printer before it arrives.

The Role of Inkjet Printers

Summed up in one phrase: most are cheap little printers for home use.

If you want a neat little printer that produces colour photographs then you will buy an inkjet. We can’t really recommend a good one; we don’t believe there are any. We have a certain amount of time for HP’s OfficeJet series, there are a lot of them out there and most people have been happy with them. Brother printers are usually good value, lots of features for the money.

If you want photography (or giclée reproduction of art) then you need an inkjet. The photographic quality of Canon’s printers usually get a good review.

Read more...

If you want to make t-shirt transfers or turn the printer into a labelling machine the choice is usually an Epson with its Piezoelectric printhead. Epson don’t like people “abusing” their printers for industrial purposes but it’s all part of the game.

Industrial quality “pagewide” and wide-body printers are usually quite reliable. That is how we know manufacturers can build a reliable inkjet. However a good service station is quite an expensive object – the mechanism for a Designjet is over £120 and hence you do not get such a thing in ordinary inkjets.

If you want a lasting printer for business purposes buy an office-quality laser printer for more than £300. It will cost more to buy but will cost a lot less to run and all the main manufacturers (HP, Canon and Brother) have some spares available.

If you really do want an inkjet despite everything said above (yes, we were trying to put you off) then look at the HP OfficeJet Pro-X and PageWide series. These use inkjet technology but they have much better service stations. HP claim they are “cheaper to run than a laser printer”. That is sometimes true but the comparison tends to be with small and mid range printers rather than the big laser printers. Ownership costs for printers are more about marketing appeal than technology.

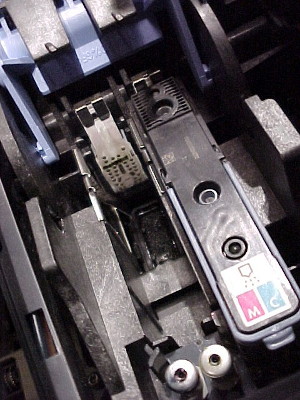

Innards of an inkjet. The printhead on the left has been removed and at the rear of the space the white strip holds the contacts. Clean it with a damp cotton bud, then let it dry.

The same goes for the electronic contacts on the cartridge. The four big contacts to the right are the “killer chip”; the brands view this as an important function so it gets nice big contacts!

Spares Availability

For professional wide-body printers HP, Epson and Canon make a full range of maintenance kits and spares available.

For domestic and small office printers HP make rather little available: basically the power supply and the printhead. Although Epson and Canon make spares lists available, in practice the parts prove too expensive compared with the price of a printer. Brother make a wide range of parts available, some at reasonable prices. If it’s the printhead it will be quite expensive; you will be lucky to get the setup software and the probability is that it will be cheaper to get a new printer.

Read more...

By the way there are no distributors guaranteeing next day spares delivery for inkjets and we aren’t promising it either. If a part is not in stock in UK distribution it normally takes 5-7 days to arrive but with some inkjet brands that has been known to extend to months. Don’t tell us your business needs this part now! – We can’t make print brands respond; it isn’t in our control.

The print brands make spares available to meet their warranty and service contract obligations. They aren’t very responsive about warranty. If you don’t have a service contract they don’t really care about providing spares and do it a bit reluctantly as a sort of social obligation – if at all.

Making Printheads Work

So now you are stuck?

Not quite. If you Google your printer model number there will be loads of forums giving advice. Much of it is anecdotal, like “I had an HP printer and the printhead failed after a year but the Canon I have now has lasted four years”. But if printhead failure is circumstantial and semi-random it would take great numbers of reports to amount to a pattern.

Deriving meaningful statistics from social media is an interesting exercise. Big IT brands attempt it. So far as we can tell there is no reliable choice between Brother, Canon, Epson and HP. Each forum has people saying they would never buy another. Inkjets are generally a bit unsatisfactory – but hey, they’re cheap.

Every now and then, someone swears they will buy laser printers in future and we cheer; someone saved from inkjet hell.

Contacts

When a printer reports the printhead or a cartridge is not present when it visibly is, there is a contact problem. Miss-seating, dirty or eroded contacts. Possibly miss-seated or fractured trailing cables. Possibly damaged printhead or printer logic. (But see above, it’s almost never the logic)

Read more...

Note that the cartridge and printer contacts are likely to be static sensitive. Wear an anti-static strap or ground yourself before working on them. Don’t touch them unnecessarily. But you do have to touch them with something!. There must be someone out there offering antistatic cotton buds, but honestly – how much do you want to spend on attempting to fix things? Ordinary cotton bud then.

Inks are often acid in nature. Acid won’t normally cut through gold but if the gold is thin and worn it will attack the copper tracks underneath and it will be difficult to get a reliable contact. How ink makes its way from the printhead to the contacts can be a bit mysterious. One route is that the wiper-blade flicks it all over the place. Inkjets also create a certain amount of particulates – ink drops that missed the paper and get airborne.

Don’t use acetone on the contacts – it will almost certainly destroy the plastic. We can’t recommend contact cleaner either because of its uncertain reaction with other parts of the printer – except perhaps as a last resort.

Ink in a printhead is intended to stain things. Ink is extremely messy and quite capable of dyeing enamel and aluminium pans – as well as all known kitchen surfaces, clothing and hands.

Read more...

Ink isn’t very toxic, manufacturers avoid that. Nor is ink guaranteed non-toxic, you aren’t meant to be in continual contact with it. There are edible inks (actually food dyes) – don’t presume those in an ordinary cartridge are.

If you have any doubt about ink, toner or cleaning substances get the manufacturers MSDS. Usually a search phrase on the lines of …

isopropyl MSDS filetype:pdf

… yields immediate results. The phrase filetype:pdf

biases the search towards portable document format (PDF) which are easily stored in your computer.

The most likely problem from attempting to fix a printhead is “Attack by Maddened Spouse” (or mother) owing to mess.

Printhead

Don’t touch the printhead nose with your fingers at all. (By nose, we mean its active surface). Fingers leave prints because they are always greasy. If you look at a finger under a microscope the pores are like volcanoes. If you plan to work on a printhead in any serious way you should probably wear rubber gloves anyway as the ink won’t just rinse away. But mainly, the printhead needs protection from you.

Read more...

As noted previously, the nozzles in printheads are small. As a rough guide, coarse human hair is about 180 microns in diameter and very fine hair 18 microns. A 1 picolitre nozzle is about 8 microns diameter . Individual inkjet droplets are intended to be below the threshold of visibility and the nozzles they come from are as well. Printheads differ, but those made for for home printers with photographs in mind all use fine nozzles and if something greasy gets stuck in there it will not easily come out.

Anything with fine but irregular strands like tissue or toilet paper probably shouldn’t come into contact with the head because there is a risk that strands will break off in the nozzles. Lint-free cloth should be OK and so should some types of cotton bud. Some people seem to like baby-wipes which are often fairly lint free and soaked in alcohol. They often contain soaps (good) and perfume (potentially bad) as well.

Water as Solvent

Once ink has dried in the wrong place getting it back towards liquid may be very difficult. To give a related example, gloss paint is very difficult to shift unless you use caustics to break down the molecular bonds or dichloromethane to swell and dissolve the material. Paint strippers are likely to destroy printhead plastics and take the thin film resistors clean out of the head.

Read more...

Most inkjet printers use “aqueous” inks. In other words, at least half of the ink vehicle is water. Tapwater shouldn’t be used because that contains various microscopic impurities. Fluorine may be good for children’s teeth but is not for inkjets. Bottled water is little or no better. Fizzy bottled water is mild carbonic acid so that won’t help. De-ionised water isn’t adequate. Ideally use distilled water which motor accessory shops and larger supermarkets sell to top up batteries.

Recovering a printhead is not a certain art.

Try standing the printhead with its nose in water – on a support like a spoon or nailbrush to let the water circulate a bit. Since most printheads are meant to handle water, it shouldn’t harm them.

Go Boil Your Head

Read more...

Detergents that might leave a residue are obviously not a good idea. Liquid detergents seem plausible.

Wikipedia on isopropyl

Wikipedia on isopropylIsopropyl

Read more...

Isopropyl boils at just under 83 centigrade. Most isopropyl is mixed with water and has a slightly lower boiling point, so as water get hotter it leaves the solution. Be wary of the fumes.

Isopropyl is used as hand sanitiser and as windscreen de-icer however we can’t recommend using them instead of isopropyl as they have additives such as soap that may tend to clog nozzles.

Ammonium Cleaner

Read more...

The critical ingredient seems to be ammonium hydroxide which is caustic and widely used in cleaning. A problem with household cleaners that contain it is that they also contain surfactants, scents and other things which may leave a residue. Again the reaction with components inside the printhead can only be a matter of speculation.

Another possibility is to use an ultrasonic jewellery cleaner on the nozzles. Other than leaving a stain in the cleaner we can’t think of an objection to trying it.

This wonderful picture from Zim 256 on Wikipedia demonstrates one way to get inkjet nozzles flowing – up the pressure a bit. A garden environment is desirable. It’s an Epson C20 though – 2001 vintage and fewer nozzles than today’s devices. And we don’t know whether it worked!

This wonderful picture from Zim 256 on Wikipedia demonstrates one way to get inkjet nozzles flowing – up the pressure a bit. A garden environment is desirable. It’s an Epson C20 though – 2001 vintage and fewer nozzles than today’s devices. And we don’t know whether it worked!Printhead Cleaning Kit

We don’t offer inkjet printhead cleaning kits directly – our own experience of them has not been good. On average we think they are water – possibly distilled water – with a squirt of isopropyl alcohol and a drop or two of glycol and detergent – which is more or less the formulation for ink. Some may use ammonia.

Read more...

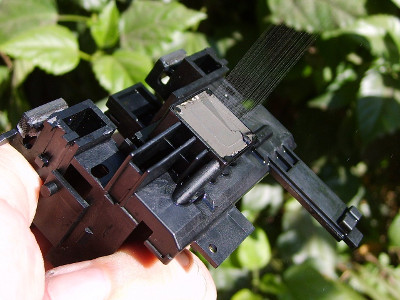

If you are quite sure you have an unshiftable streaky or no-print problem with an inkjet there is nothing to lose by trying to fix the head. We gather from various forums that people have succeeded in dismantling and rebuilding Canon printheads.

When you try to test a printhead the cartridge and printhead contacts need to be clean and dry, but the printhead itself needs to continue wet when you try it. Wipe the body but not the nozzles with a tissue. Try to get the contacts dry by gentle dabbing.

There are “professional” inkjet printhead cleaning machines aimed at some of the wide-format printers. These seem to combine cleaning fluids with a vacuum pump. Big printers can cost £5000 and printheads £500 so the complexity and time spent to recover a head may be worthwhile. To the best of our knowledge no-one offers such a service for little printers because they are too likely to prove uneconomic, waste a day of effort and achieve nothing.

So why isn’t it easier?

You might wonder why the printer manufacturers don’t give an approach to fixing a printhead. After all they would get to sell more ink if the printer were fixed. They monitor the forums and online generally and know cleaning and printhead issues are a hot topic. In the research labs they will have people who know. After all, testing things will break a lot of printheads.

Read more...

- In any specific case exactly what has gone wrong is probably unanswerable without cutting the thing up and, since we are working at microscopic scale, probably just outright unanswerable.

- In a lot of cases the answer will be that “compatible ink” didn’t perform as hoped – but people don’t like being told that.

- Simply selling a new printhead is less trouble.

- If they get free support some people will take up a lot of time on the phone. Technical support never costs less than £40 per hour to deliver – about 3 times the wage of the person providing it.

- Inkjet reliability is an issue the print brands don’t address. With the old-style integrated cartridge and head the printer could be potentially as reliable as dot matrix, if not more so. In practice this reliability didn’t happen. HP seems to have a habit of designing gears that are underrated for the job.